How Do Press Brake Electrical Components Enhance Safety and Efficiency?

Table of Content

Introduction

Main Electrical Cabinet

Power Supply Guidelines for 220V Machines

Key Electrical Components

Cable and Wiring Standards

Safety Measures and Maintenance Tips

Are your press brake electrical components designed to deliver both safety and efficiency? Reliable electrical systems are the backbone of seamless and secure bending operations, ensuring optimal performance and minimizing risks.

Introduction

The electrical components in a press brake are responsible for critical functions such as power distribution, safety interlocks, and emergency shutdowns. Properly maintaining and configuring these components not only enhances operational efficiency but also significantly reduces the likelihood of accidents and unplanned downtime.

Main Electrical Cabinet

The electrical cabinet is the heart of a press brake's electrical system, housing components that ensure smooth and reliable performance. Below, we delve into the key elements that contribute to the machine's functionality and safety.

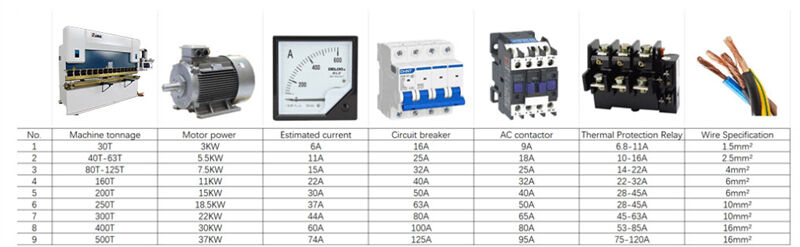

Press brake machines, like all industrial equipment, require precise electrical configurations to operate safely and efficiently. Selecting the appropriate power cable is a critical step, with current capacity being a primary consideration. To determine the correct cable size, start by calculating the maximum current draw of the machine, which depends on factors such as motor specifications, hydraulic system demands, and other electrical loads.

For your convenience, we provide the following reference table to assist in selecting the right components:

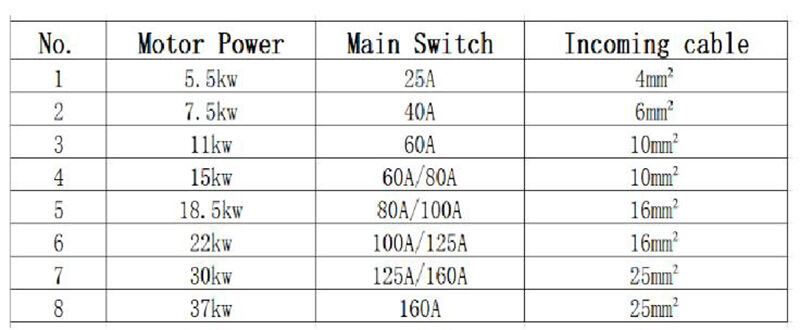

Power Supply Guidelines for 220V Machines

Many press brakes operate on a 220V power supply, making them ideal for small workshops or light-duty applications. Below is a reference chart to help you choose the correct main switches and cable sizes based on motor power. Always ensure the power supply is stable and properly grounded to avoid operational issues.

Key Electrical Components

Understanding the electrical components of a press brake is essential for safe and efficient operation.

Here’s an overview of the most critical elements:

Power Supply: Most press brakes require a three-phase power supply, with common voltages including 220V, 380V, or 440V, depending on the machine's size and capacity.

Circuit Breakers: These protect the electrical system from overloads and short circuits by interrupting the current flow during faults. The breaker’s amperage rating must align with the machine's maximum current requirements.

AC Contactors: These electromechanical switches control the power supply to the motor, enabling safe activation and deactivation of high-current circuits through the machine’s control system (e.g., PLC or manual switches).

Emergency Stop (E-Stop) System: Equipped with strategically placed buttons, this system ensures immediate power cutoff during emergencies, connected via safety relays or contactors for rapid response.

Control System: Advanced press brakes use Programmable Logic Controllers (PLCs) to manage operations such as bending speed, backgauge positioning, and safety interlocks, ensuring precision and reliability.

Limit Switches: These devices monitor the position of moving parts like the ram or backgauge, providing feedback to the control system to prevent overtravel and enhance accuracy.

Transformer: Used to adjust voltage levels to meet the requirements of specific electrical components.

Grounding: Proper grounding is vital for electrical safety, protecting operators from shocks and ensuring compliance with local regulations.

Safety Features: Beyond E-Stops, press brakes may include light curtains, safety mats, or two-hand controls to further mitigate risks.

Cable and Wiring Standards

Selecting the right power cable involves evaluating the machine’s maximum current draw, which is influenced by the motor, hydraulic system, and other electrical components. Proper cable sizing and installation are crucial to prevent overheating and ensure long-term reliability.

Safety Measures and Maintenance Tips

The electrical components of a press brake are pivotal to its performance and safety. From the control panel to the hydraulic systems, every element must function harmoniously to achieve high-quality results. By investing in premium press brake components, adhering to regular maintenance schedules, and prioritizing safety, you can maximize your machine’s efficiency and extend its operational lifespan.

For more information, explore our range of press brake solutions or contact our technical support team for personalized assistance.