Press Brake Preparation Steps – Detailed Operating Guide

For first-time operators of the JUGAO Hydraulic Bending Machine, correctly

starting and setting up the machine can be challenging. Improper setup may lead

to reduced bending accuracy, mold damage, or even affect the equipment’s

lifespan.

This guide provides a detailed breakdown of the key steps in preparing the bending machine, ensuring precise bends every time while improving production efficiency and processing quality.

Press Brake Preparation Steps

Follow this procedure to ensure proper startup and stable operation:

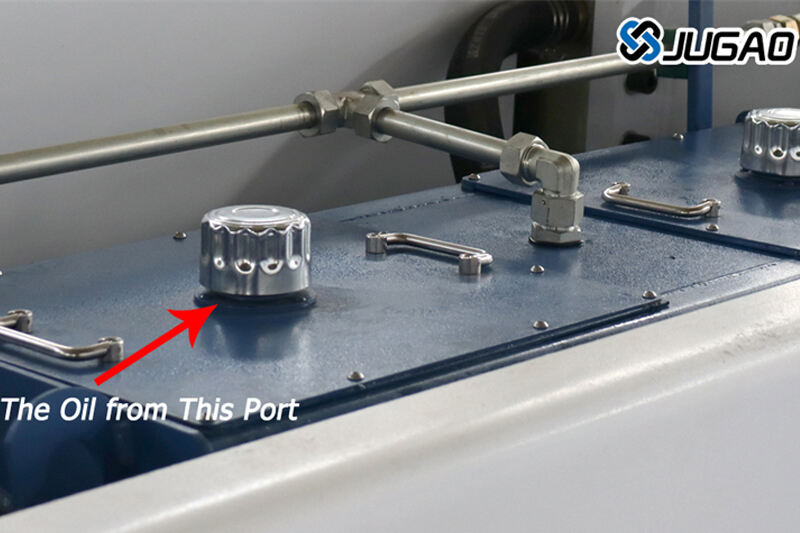

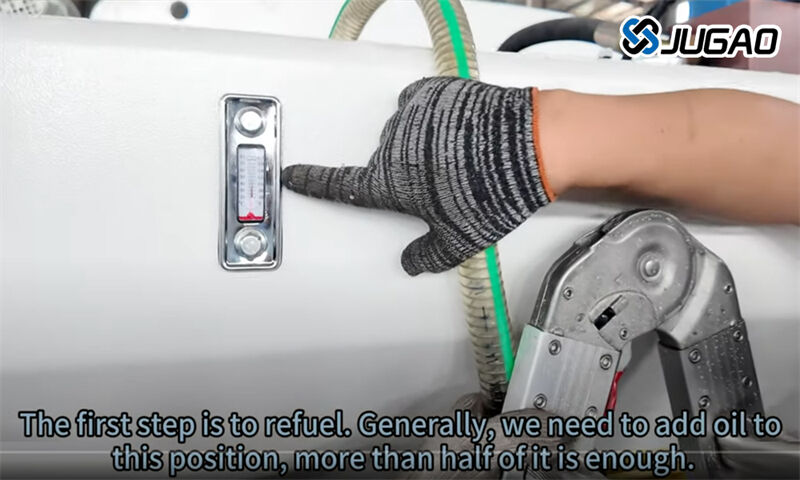

1. Fill with Hydraulic Oil

Use No. 46 anti-wear hydraulic oil, maintaining the oil level at the midpoint of the gauge.

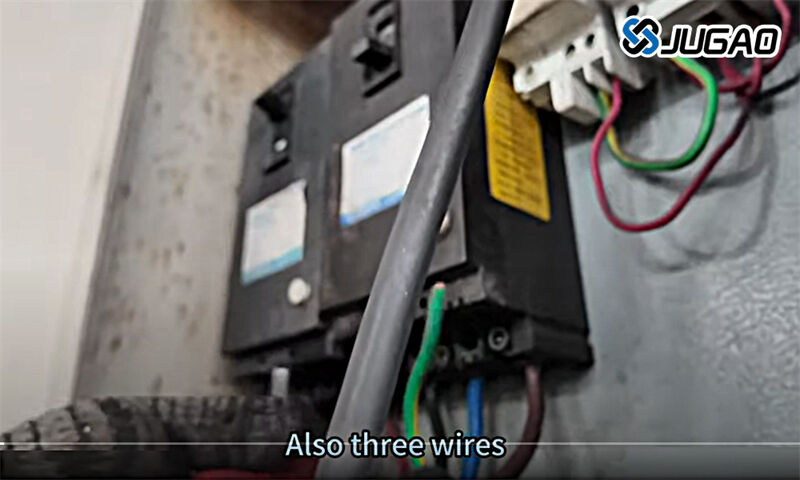

2. Power Connection

Ensure stable power supply (3-phase 380V ±10%) with proper grounding.

3. Install Foot Pedal Switch

Connect the foot control cable and test the emergency stop function for responsiveness.

4. Start the Hydraulic Pump

Release the emergency stop button, briefly start the pump, and observe if the pressure gauge reads normally.

Press the "Oil Pump Start" button on the control panel (jog mode)

Observation:

1. Motor direction (direction indicated by the sign)

2. Instantaneous value of pressure gauge (should be ≤2MPa)

3. Abnormal sound detection (with the assistance of a stethoscope)

5. Check Motor Rotation Direction

Start the main motor briefly and confirm the fan rotates clockwise (reverse rotation requires adjusting the power phase sequence).

6. Formal Operation

After confirmation, power on and conduct a no-load test to ensure smooth operation of all components.

By following these steps, you can ensure the bending machine operates at peak performance, minimizing errors and maximizing efficiency. For further optimization, regular machine calibration and mold wear inspection are recommended.

Video Demo

https://www.youtube.com/watch?v=oAq44kwGxDI&t=392s