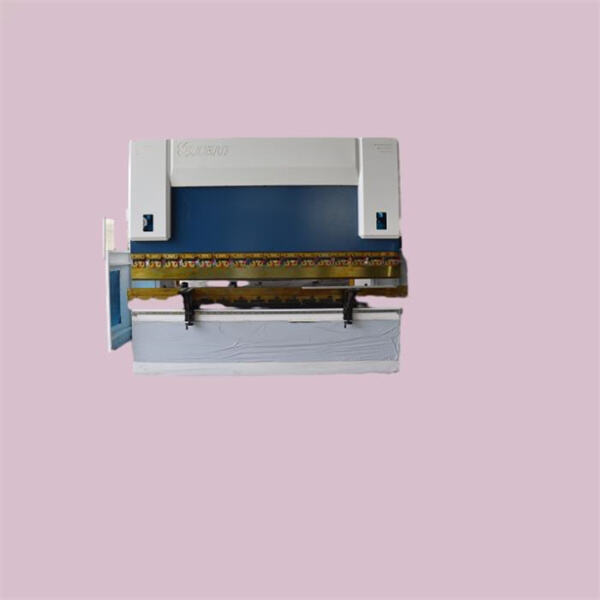

If you have ever seen a cool bent piece of metal on an incoming car part or around your toaster and fridge, then this may be the story for this modest-looking tool. That's where a press brake machine comes in handy for bending them. It takes great power and strength to bend the metal sheets into what we desire.

Simple as this press brake sheet follower is a specially designed tool that keeps the metal sheet steady when bend. This results in the sheet never shifting or moving out of place, to guarantee that after removing it from your printer you have a final product exactly how its supposed to look.

Working with this tool is not only about controlling things, but also time-saving and money-consciousness. How does it do that? In this way, the workers can indeed make finest quality metal ores and avoid wasting less of it. Press Brake Sheet FollowersCommitted fabricators make use of press brake sheet followers to enable these people perform their work promptly and also precisely.

Press brake sheet followers come in various forms and each one operates through its own unique process. Manual types are the ones require a man to handle them on bending. The other kinds are automatic, able to twist the metal into whatever form it needs and adjust themselves for however thick a sheet of metal they start with. Easy, enabling consumer=open-rate of up to "busiest times. "

So now Lets talk about the advantages offered by a press brake sheet follower. Here are the highlights!! The greatest advantage of this is the unified loading and how all the products would visually look alike. Every product consistent in itself makes customer happy and increase his trust on the quality for whatever he buys.

The task of bending metal becomes easier and quicker due to the presence of Press brake sheet followers as well. The employees can get the work done faster and with less flaws, which would also minimize the time needed for adjustments. This allows them to engage in more projects and better fulfill the expectations of their customers.

Consistency is a big problem in making metal products. Parts made of metal may not be compatible if these conditions are unsatisfied, meaning they will no longer fit together properly or produce the intended functionality. A press brake sheet follower ensures every bend is made just the way it should be.

recognize significance RD Press brake sheet follower. laser cutting machines, rolling machines pipe bending machines, products, provide entire range after-sales services includes Spanish after-sales service ensure customers enjoy hassle-free use. addition continue invest research development, help promote latest technology product development meet ever-changing needs customers, assist customers maintain position marketplace.

Press brake sheet follower efficiency precision, laser cutting machines handle wide range different materials. Rolling machines, outstanding forming capabilities speedy production meet demands many clients. Pipe bending machines utilized mass production due versatility stability. embody essence latest industrial technology enable manufacturing sector adapt various challenges quickly, precisely high degree flexibility.

Rolling Machines specialize metal sheet forming high-quality production. Press brake sheet follower offer flexible solutions pipe bent. product line centered around precision, efficiency stability order increase effectiveness quality products.

Quality Builds Trust. We dedicated sheet metal machines ensure every machine is par standards industry. committed providing highest quality products customers. laser cutters press brakes, pipe bending rolling machines.Rapid Market Response: leveraging efficient production supply chain management, quickly meet demands market. time deliver reduced week, if enough stock. enables rapid equipment purchases gain Press brake sheet follower advantages.