Enhancing Bending Efficiency with V-Opening Multi-V Die Press Brakes

Are you facing challenges with inconsistent bending results or frequent tooling changes? A V-Opening Multi-V Die Press Brake could be the solution to elevate your metalworking precision and operational efficiency. This advanced tooling system offers unparalleled flexibility, allowing for quick adjustments to accommodate diverse bending requirements without the need for multiple die sets.

Understanding Multi-V Dies: A Versatile Tooling Solution

A Multi-V die, also known as a multi-groove die, features multiple V-shaped grooves of varying widths on its sides. This innovative design enables operators to swiftly switch between different V-openings by simply rotating the die block, significantly reducing setup time and enhancing workflow efficiency. Each V-opening is tailored to specific material thicknesses and bend radii, making it an indispensable tool for modern press brake operations.

Key Benefits of Multi-V Dies:

Reduced Downtime: Eliminates the need for frequent die changes, keeping production lines running smoothly.

Enhanced Precision: Ensures consistent bend quality across different material types and thicknesses.

Cost Efficiency: Minimizes the investment in multiple single-V dies by consolidating functionality into one versatile tool.

The Critical Role of V-Opening Selection

Choosing the correct V-opening is paramount to achieving optimal bending results. The general rule of thumb is to select a V-opening that is 6 to 12 times the material thickness. For example:

A 4 mm thick sheet typically requires a V-opening between 24 mm and 48 mm.

A 10 mm thick material may need a V-opening ranging from 60 mm to 120 mm.

Why V-Opening Matters:

1. Bend Quality: The right V-opening ensures a smooth bend with the desired radius, avoiding defects like cracking or wrinkling.

2. Tool Longevity: Proper V-opening selection reduces stress on the punch and die, extending their service life.

3. Material Integrity: Prevents excessive force that could compromise the structural integrity of the workpiece.

Step-by-Step Guide to Changing V-Openings

Follow these steps to safely and efficiently adjust the V-opening on your Multi-V die:

1. Power Down and Secure the Machine

Ensure the press brake is completely powered off and locked out to prevent accidental activation.

Follow lockout/tagout (LOTO) procedures to guarantee a safe working environment.

2. Loosen the Die Retention System

Use the appropriate tools to slightly loosen the clamps or bolts securing the die. Avoid removing them entirely to prevent the die from falling.

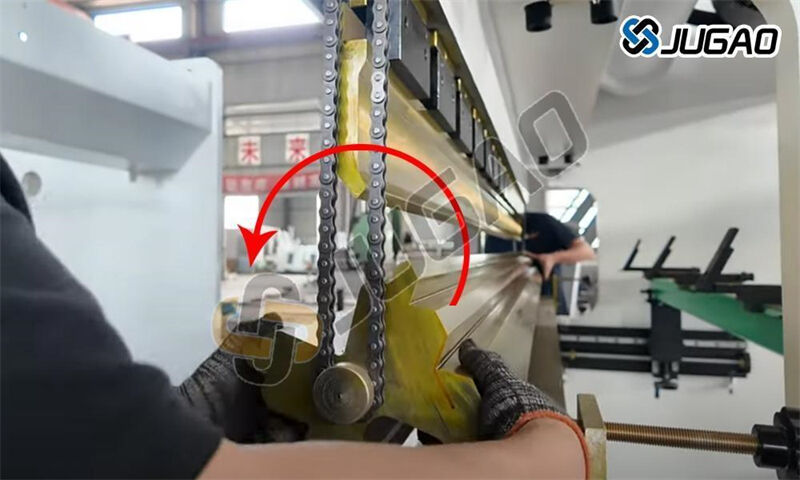

3. Lift and Rotate the Die

Gently lift the die to disengage it from the holder. For heavier dies, employ lifting equipment to ensure safety.

Rotate the die to align the desired V-opening with the bending axis. Most dies are marked for easy identification of groove sizes.

4. Secure the Die and Verify Alignment

Lower the die back into place and tighten the clamps or bolts securely.

Double-check the alignment to ensure the die is perfectly seated and level.

5. Adjust Machine Settings

Update the press brake's control system (e.g., Delem DA66T, E21) with the new V-opening dimensions, material thickness, and bend angle.

Reposition the backgauge to accommodate the new setup.

6. Conduct a Test Bend

Perform a trial bend on scrap material to validate the setup. Make fine adjustments to the backgauge or punch position if necessary.

Safety Best Practices

Working with press brakes demands strict adherence to safety protocols:

Personal Protective Equipment (PPE): Always wear safety gloves, goggles, and steel-toe boots.

Proper Handling: Use mechanical aids for lifting heavy dies to prevent injuries.

Regular Inspections: Check dies and tooling for wear or damage before each use to avoid accidents.

Conclusion

The V-Opening Multi-V Die Press Brake is a game-changer for metal fabrication, offering unmatched flexibility and efficiency. By mastering the process of changing V-openings and adhering to safety guidelines, operators can achieve superior bending results while maximizing productivity. Invest in the right tooling and techniques to transform your press brake operations and stay ahead in the competitive manufacturing landscape.