Hydraulic clamping system: the core technology to improve the performance of bending machines

Table of contents

1. Guide to the whole process of mold replacement

2. Key points of hydraulic clamping system operation

3. Video operation demonstration

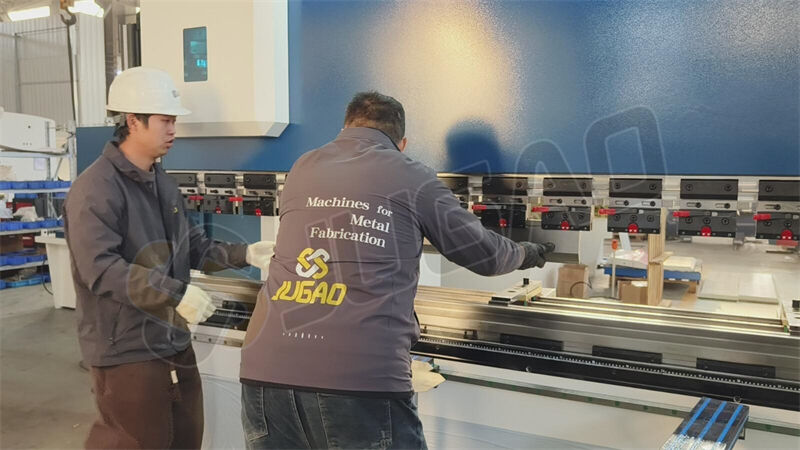

In the field of modern metal processing, hydraulic clamping system has become a key configuration to improve the operating efficiency of bending machines. This innovative system uses hydraulic power to quickly lock the mold, greatly improving processing accuracy and production efficiency.

As an important optional component of the bending machine, WILA brand has developed this revolutionary hydraulic clamping solution after years of technological accumulation. Its outstanding advantages include:

3-4 seconds to complete mold clamping

One-time calibration and lifelong adjustment

Supports double-sided mold installation and automatic centering

A full set of mold replacement takes only 3 minutes

The mold can be freely moved and positioned

Standardized process for mold replacement

Step 1: Release the hydraulic lock

During operation, lightly touch the soft switch on the control panel to release the hydraulic lock. The system will automatically enter the safety protection mode, at which time the equipment operation function will be locked, and the screen will display a warning message to ensure that the equipment cannot be started before the mold is properly fixed, effectively preventing operational risks.

Step 2: Mold disassembly tips

Find the spring locking device and press it continuously to safely release the mold. This design ensures that the disassembly process is smooth and controllable to avoid damage to the mold. Special attention: Be sure to cut off the power supply before operation and take safety precautions.

Step 3: New mold installation specifications

When installing a new mold, keep the spring button pressed continuously and push the mold accurately into the slot. After confirming that it is in place, release the button to complete the locking. It is recommended to perform a trial bend test after installation to verify the stability of the system.

Hydraulic clamping system activation

After completing the mold installation, click the soft switch on the control panel again to activate the hydraulic clamping. The system will automatically complete the pressure calibration, and the equipment can be put into normal use at this time.

This intelligent clamping system not only simplifies the mold replacement process, but also provides reliable protection for operators through multiple safety protection mechanisms. Its fast response characteristics increase the efficiency of mold switching in mass production by more than 60%, making it an ideal choice for modern sheet metal workshops.