Bend Shape Basics

1. L-bending processing

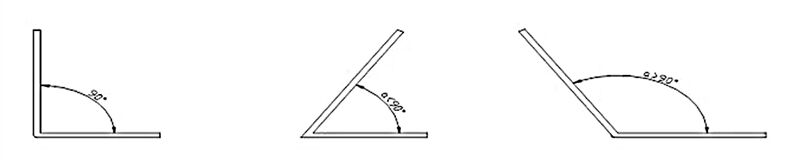

The basic shape of the bending, the bending angle is between 30 degrees and 180 degrees.

When bending sharp angles, you need to select a deep lower die and a sharp upper die. When bending 90 degrees or obtuse angles, you can choose any die for processing.

(1) The positioning principle of L-bending processing a: The principle of positioning is to use two rear gauges (two points) and position according to the shape of the workpiece. b: When positioning a rear gauge, pay attention to the deflection and require it to be on the same center line as the bending size of the workpiece. c: When bending small bends, reverse positioning processing is the best. d: It is better to position it in the middle and lower part of the rear gauge (the rear gauge is not easy to tilt when positioning). e: The positioning side is closer to the rear gauge. f: It is better to position it on the long side. g: Use a jig as an auxiliary positioning (positioning and bending of beveled and irregular sides).

(2) Precautions for L internal bending

a: When bending with the mold in place, the rear gauge needs to be pulled back to prevent the workpiece from deforming during the bending process;

b: When bending a large workpiece internally, the workpiece has a large shape and a small bending area, making it difficult for the tool and the bending area to overlap, resulting in difficulty in positioning the bent workpiece or damage to the bent workpiece.

(3) Precautions for L external bending

a: When bending a small size, check whether the upper die and the rear gauge interfere with each other;

b: When the hole is close to the bending line or the bending edge size is less than half of the V groove, pay attention to the bending pull.

(4) Special bending methods for L bending

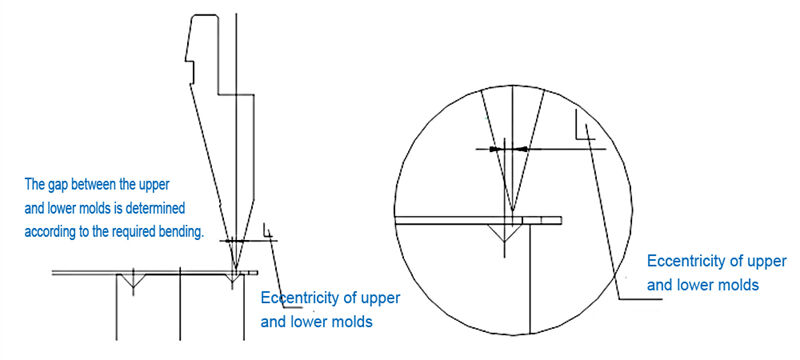

a: Eccentric bending method

Eccentric bending has the difference between the positive and negative installation of the lower die. During processing, the difference is made depending on whether the pull is on the inside or outside of the bending line. In addition, eccentric bending is a special processing method with certain risks. It is not used unless under special circumstances.

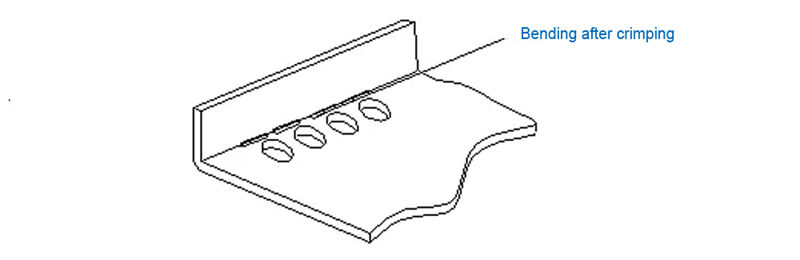

b: Bending after crimping

Since eccentric bending has a shearing effect, it is not suitable for some products with high surface requirements. The timing of crimping bending is the same as that of eccentric bending. Before bending, you can use an 88-degree tool or a special crimping die to crimp the bending line, and then use a normal die to bend.

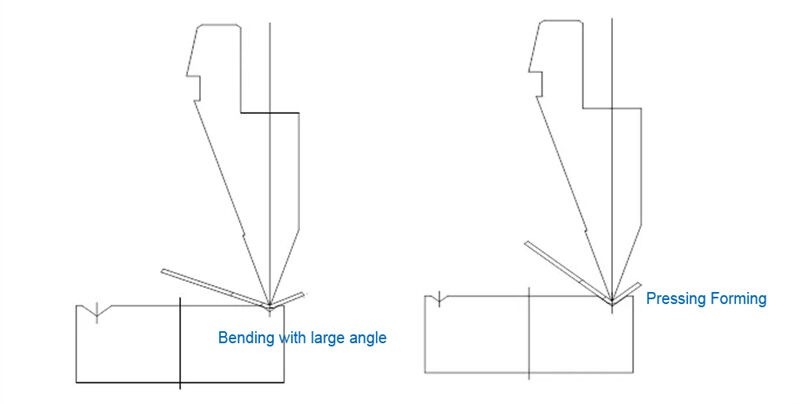

c: Small V-bending with large angle and large V-pressing

First bend with a small V groove to a large angle, and then bend with a normal die. This processing method can avoid the small unfolded size caused by direct bending of the small V groove.

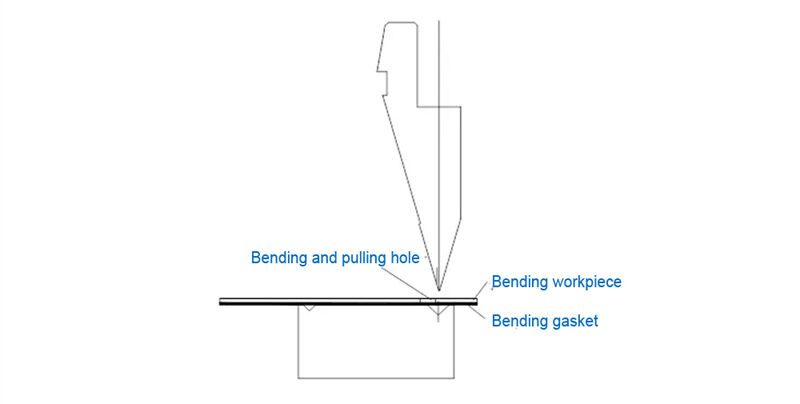

d: Bending with gasket and material

This processing method is mostly suitable for products with strict requirements on the appearance of the workpiece. In addition, due to cost considerations, it is mostly limited to sample processing.

The above four processing methods can also be used in combination, and the molding effect will be more ideal.

2. Z-bending processing

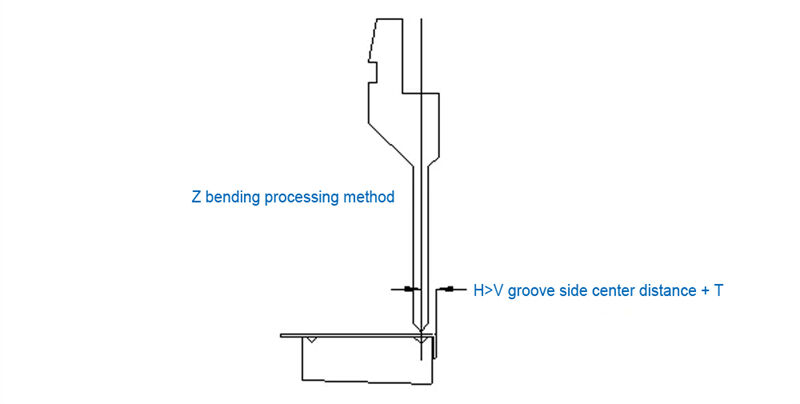

Any bend that is formed into one reverse and one positive is a Z-type bend.

The processing range of standard bending: Z-bending height>V-groove side center distance plus T.

The minimum processing size is limited by the mold used in the processing, and the maximum processing size is determined by the shape of the processing machine.

(1) Z processing Z steps

a: First process L fold according to the L fold processing method;

b: Process Z fold with L fold positioning; (or process Z fold with the other side of L fold.)

(2) Z processing Z fold positioning principle

a: Positioning premise, convenient positioning, good stability;

b: Generally, positioning is the same as L fold;

c: The workpiece and the lower die are required to be flush during the secondary positioning processing;

(3) Z processing precautions

a: The processing angle of L fold must be in place, generally requiring about 89.5 degrees to 90 degrees;

b: The rear setting gauge should be set to pull back to prevent the workpiece from deformation.

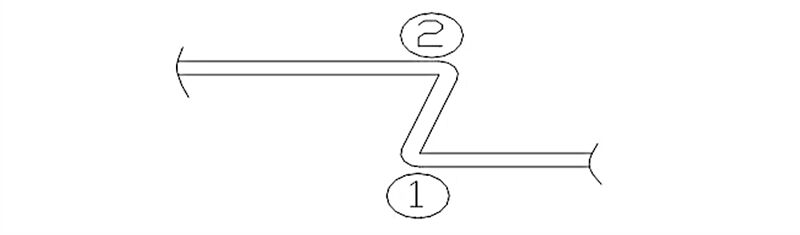

(4) Z general processing method

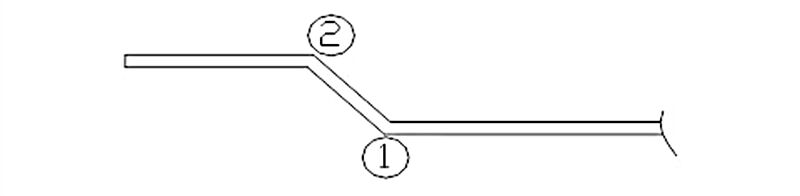

a: The processing order should be considered in the figure below, first bend 1 and then bend 2;

b: Another type of first bend L and then process Z fold, and confirm whether the Z fold processing interferes with the machine;

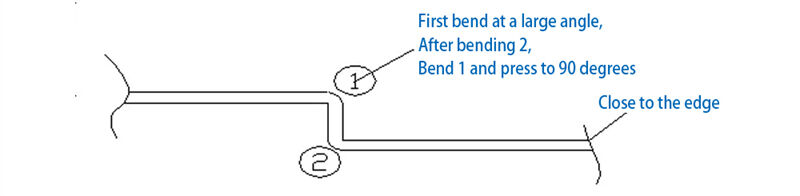

If there is interference, first bend 1 to a large angle, then bend 2, and then press 1;

If there is no interference, follow the general Z fold processing method, first bend 1 and then bend 2;

c: Two sharp-angle Z bends, first bend to 90 degrees, then insert 2, and insert 1;

(5) Special processing methods for Z-bending:

a: Eccentric processing of the lower mold;

b: Processing with a small V-groove;

c: Bend at a large angle first and then pressurize;

d: Use a grinding lower mold;

(6) Other processing methods for Z-bending:

a: Processing with a step-down mold:

b: Processing with an easy mold:

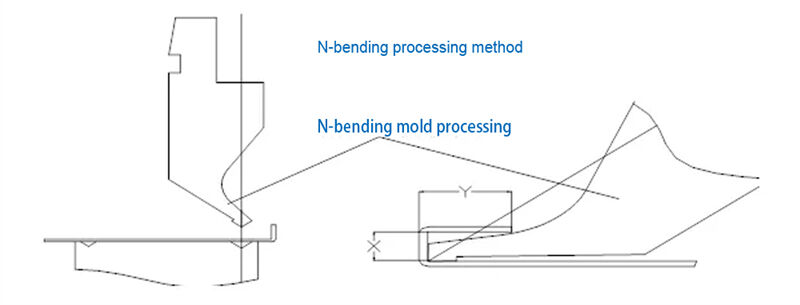

3. N bending processing

Continuous processing twice on the same processing surface is called N-fold processing.

(1) General processing precautions for N-bending:

a: The processing angle of the first fold should be less than or equal to 90 degrees;

b: When processing the second fold, the final gauge should be based on the processing surface as the reference surface.

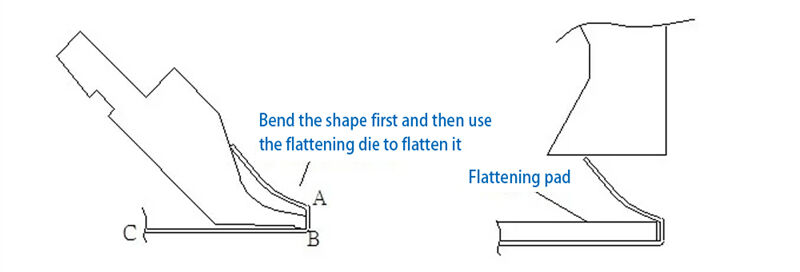

(2) Special processing methods for N-bending:

a: When the Y dimension of the N-bending interferes slightly with the upper die ==> After bending N-bending, use a flattening die to shape it;

b: When the Y dimension of the N-bending interferes greatly with the upper die ==> After bending A, bend it to the interference point, bend B-bending with C as the support, and then use (flattening die + padding) to shape it;

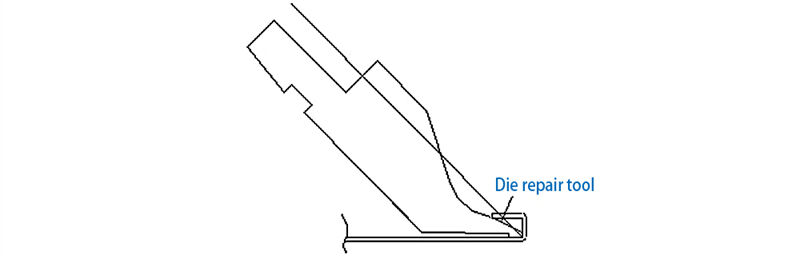

c: Process with a die repair tool;

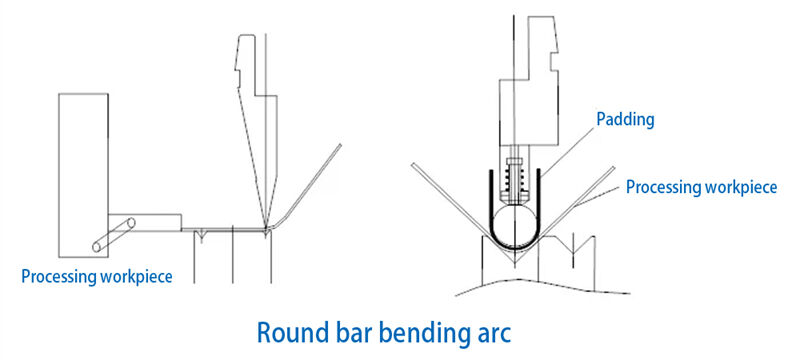

4. Arc processing

Arc processing is divided into two types: using a bending die to cut a circle and using an arc knife. The arc knife is divided into two types: fixed type and round rod type.

Processing precautions:

a: When using a 90-degree lower die for processing, the processing may not be in place, so it is necessary to push it by hand or choose an 88-degree lower die if conditions permit;

b: Use more inspection jigs to ensure the appearance size of the workpiece;

c: When processing a 90-degree arc, choose 2 (R+T) for the lower die.