Press brake bending is a neat way to put metal sheets into their desired shape. If you’re interested in finding out more about tandem press brake, continue on with this guide to fine tuning your craft even further.

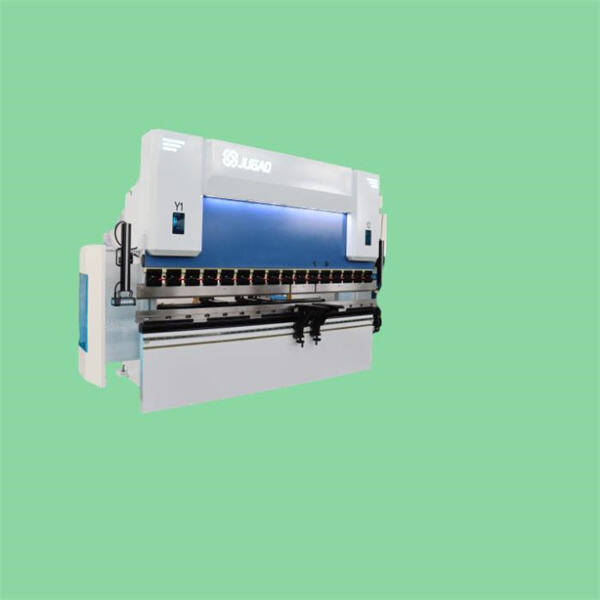

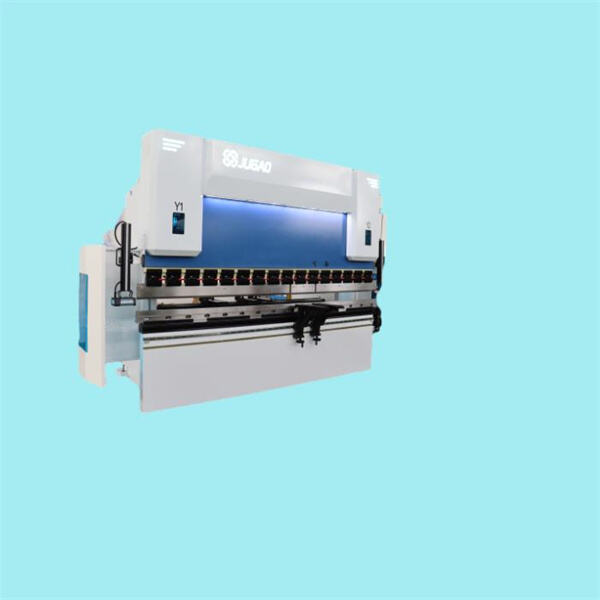

Press brake bending may sound difficult, but it’s pretty easy once you understand it. First thing is, you need a press brake machine. It’s a big machine that can make big sheets of metal bend. It comes with a special tool known as a punch and die that work in tandem to bend the metal. You simply slip the sheet of metal between the punch and die and press a button to bend it. It's like magic!

There is some must-know practices to become good in tandem press brake machine. One trick is to measure the metal sheet carefully before you bend it. You’ve also got to make sure the punch and die are correct to obtain the proper angle and shape. Keep going and soon you’ll be bending metal like a pro, because practice makes perfect!

There’s more than one way to bend metal with a press brake machine. One of this favorite methods is known as air bending in which the metal is only partially bent between the punch and die. Another method is known as bottoming, in which the metal is bent to the bottom of the die. Each method has its strengths and weaknesses, so it’s important to understand how they differ, and choose the right method for your project.

Caring for Your Press Brake Tooling and Machine is Critical for Effective Press Brake Bending. It is important that the punch and die remain in good condition to produce a clean bend. Proper upkeep, such as taking care to clean and oil the machine, is also necessary to help mitigate wear and tear. For example, when you are going to bend metal, you can also expect to get great and consistent results if you care for your machine and tools.

Here are some things you will want to keep in mind if you are looking for consistent results with the press brake machine. The first step is to double-check your measurements before bending any metal to ensure no bad calculation errors. Second, have the right tool for the job for your optimum result. And finally, don’t be in a hurry — get it set up the machine properly and make sure everything is ready before hitting the button. With these suggestions, you'll an press brake bending guru!