The tandem press brake is a crucial component of a machine that is intended to bend metal sheets in a precise manner. It functions in much the same way as an arm that moves up and down to fold the metal. Understanding how to operate the press brake axis is critical to getting good results with sheet metal. In this article, we’re going to introduce the press brake axis, learn how to use it to perform a bending operation, why it requires calibration, common situations of the press brake axis going wrong, and how to solve the problems. By getting the most out of your press brake axis, you can ensure high-quality metal bends – every time.

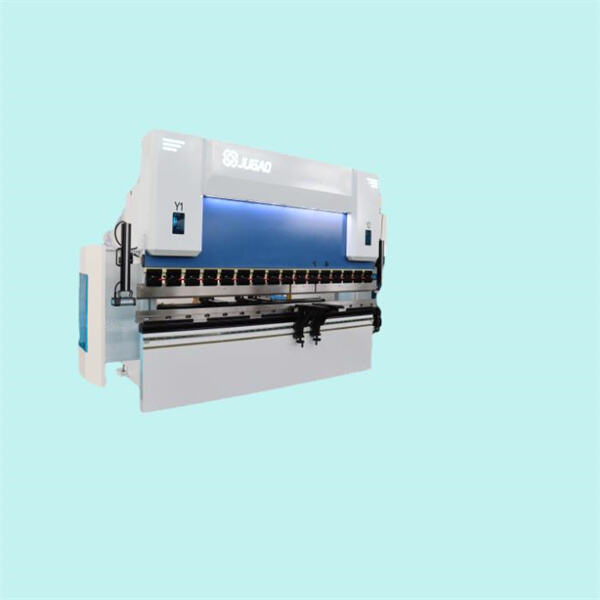

A press brake machine axes The press brake axis regulates the bending tool's motion on a press brake machine. It can travel in different directions to fold the metal sheet to your desire shape. The axis is there to ensure you put the perfect amount of pressure to make the metal bend without breaking it. When you know and make good use of the press brake axis, you will be able to use it properly for smooth bends.

To use the tandem press brake machine to correct bending, these simple steps can be taken. First off, ensure the metal sheet is clamped firmly on the machinery. Then, set the press brake axis to the accurate angle and bend you want the metal and the die to be. Now you can gently apply pressure to the bending tool, the entire length of the bend. At last, release the pressure, open the bending tool and there we have the angels with extracted metal sheet.

Accurately calibrate your press brake axis when making bent parts. The alignment of the axis may become misaligned or worn out over time, leading to crooked bends. Another side benefit to calibrating your press brake axis is that it runs effectively and gives you precision bends every time you run it. This makes your machine last longer and makes your work even better.

Every machine has issues every now and then and press brake axes are no exception. Some common complaints are that the fixtures are misaligned, get worn out, or that the controls don’t work correctly. So if you notice any of these issues, it’s important to address them fast to prevent harm to the machine. The user manual of your press brake axis or a professional that can help you troubleshoot and repair problems. You can save money and downtime by fixing problems fast.

There are several maintenance and operating steps to remember to get the most out of your press brake axis. Check and clean the machine regularly, calibrate the axis, and apply proper bending methods. That can have a number of benefits: increasing the quality of your work, extending the life of your machine and minimizing the amount of time you spend cleaning your saw. By keeping your press brake an axis properly maintained and by running it as you should be, you can expect great results every time you are working with metal sheets where this equipment is concerned.