Cool Metal Press Fabrication Metal press fabrication is a cool thing that assists in making much of the metal things. It’s sort of like the clay mold shapes you use for cute little shapes, but with metal! This is part of the recipe that makes things so strong and hard.

With press steel production, it is when metal sheets are cut and formed into specific sizes and shapes with very close tolerances. It is similar to making shapes out of metal with a big cookie cutter. This matters because it allows the metal parts to mesh together exactly.

Metal press fabrication can help produce metal parts that are incredibly durable and long lasting. They are the basic building blocks of a lot of stuff — cars, machines, buildings, you name it. They are designed to be robust and can withstand heavy use. This process can also be used to create metal objects that are detailed and complex in shape.

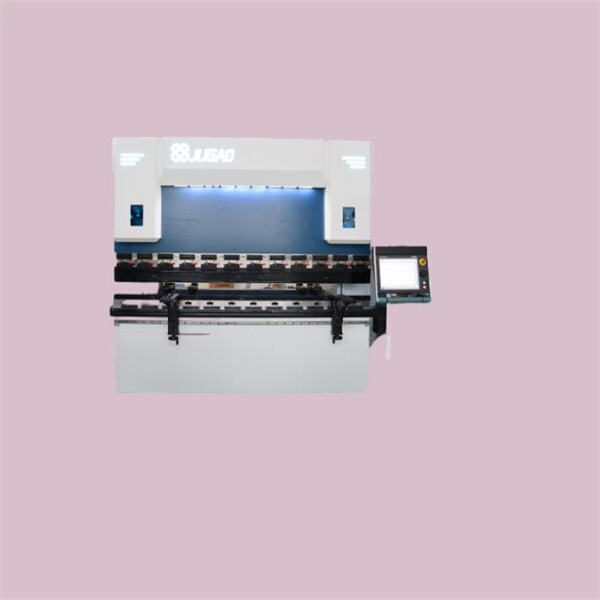

Metal press construction is a lot more modern and makes everything faster and more simple for people to be able to get. This means that we can make many metal parts fast. Machines are used to cut and shape and assemble the metal parts. Metal press fabrication has also been facilitated by technology, allowing it to meet the increasing demand for metal parts.

Putting together press metal fabrication requires professionals who will know how to handle the machines accordingly. And on the other side are specialists who are capable of producing top-notch metal parts that are safe to use. The machines are one element of the equation too, to form the metal parts to a shape precisely.

Various industries require various metals parts. Metal press fabrication can fabricate custom parts to fit individual tasks. With applications ranging from cars, to airplanes, to buildings, this process has the capability to serve these different industries. Custom metal parts make sure everything goes together just so.