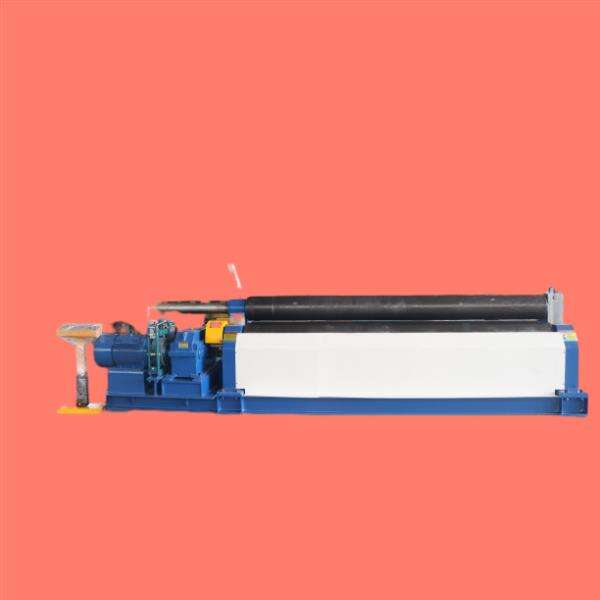

We thought we’d chat with you today about metal plate rollers. Ever wondered how metal can be twisted and bent into new shapes? Metal plate roller A metal plate roller is a special machine used to form metal plates into different shapes. Lets discover the metal plate rollers and how work!

You use pressure to bend metal plates into shapes with metal plate rollers. The metal plate feeds through the machine and is rolled down upon. This is gradually pushing the metal into the shape that we desire. It requires skill to ensure the end product is tailored just right.

Factories that rely heavy on metal to do their job, like places that make things out of metal tend to use sets of metal plate rollers. In places such as construction, cars and airplanes, machines that roll metal plate into parts and structures are not uncommon. These machines shape metal plates fast, which is critical to producing many products.

One of the amazing things about metal plate rollers is that they can create bends and curves with an extraordinary level of precision. Workers can adjust the pressure on the metal by altering the settings on the machine. This contributes to get sharp shapes. That precision is a big deal if you’re making small metal parts.

Metal plate rollers are versatile equipment that can work with a variety of metals and thicknesses. Aluminum, Steel, Copper These metal plate rollers can bend whole sheets of metal into cylinders and are even strong enough for making heavy-duty coils. These are capable of forming a wide variety of curves and bends, and so can be used for a variety of metalworking applications.

As technology allows for more advancement, steel plate roller manufacturing companies are continuously discovering new techniques to make their machines better. Some new features, such as computerized controls and automatic adjustments, have made metal plate rollers faster and more precise. It speeds up the process and helps produce quality metal products.