The CNC laser pipe cutting machines are pretty awesome, especially those from JUGAO. They assist in turning metal pipes into other shapes and sizes without making any mistakes. So let’s find out more about that — how these machines work and why they matter when it comes to making things.

CNC laser pipe cutting machines have to have a significant advantage: That they’re able to cut pipe incredibly fast and very precisely. That means less of time wasted fixing mistakes, which can save both time and money. And they can cut with great precision as well, so they can readily handle complex cuts. And they work fast, cutting through large numbers of pipes efficiently.

CNC laser pipe cutting machines have revolutionized the way things are made. People used to have to cut pipe by hand before these machines, and it would take a long time, and it wasn’t always accurate. Now, companies can cut their pipes with speed and precision, creating better products in less time. That has resulted in faster and cheaper manufacturing.

CNC laser pipe cutting is widely used in various fields. And in the car industry, such machines cut pipes for exhaust systems. In construction you cut pipes for distributing water and air. In the airplane business, they used saws to cut tubing for fuel lines. CNC laser pipe cutting technology has many applications.

Through the utilization of CNC laser tube cutting machines, larger numbers of products can be produced. These machines work nonstop, slicing pipes in a row without a break. This makes more pipes cut more quickly, which is good business, since businesses can be more productive and earn more money.

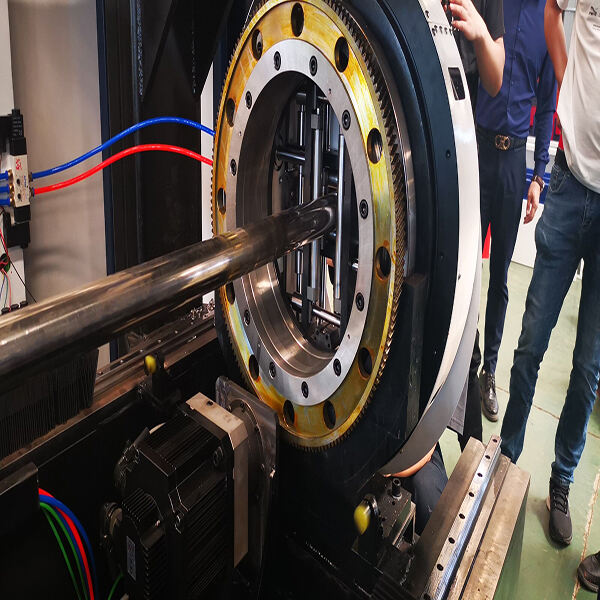

There are plenty of awesome features to cnc laser pipe cutting machines that make them so efficient. For instance, they have powerful lasers that can slice through heavy metal pipes like butter. They also have computer systems that can make the cuts extremely precise. They also have sensors to detect errors, and can correct them immediately. These features interact to bring CNC laser pipe cutting machines at the top of the preferences for manufacturing plants.