The process of CNC bending is a unique method for forming metal. The process involves a computer that helps to bend the metal just so. Metal is put in a machine, and the computer instructs the machine how much and where to bend the metal.

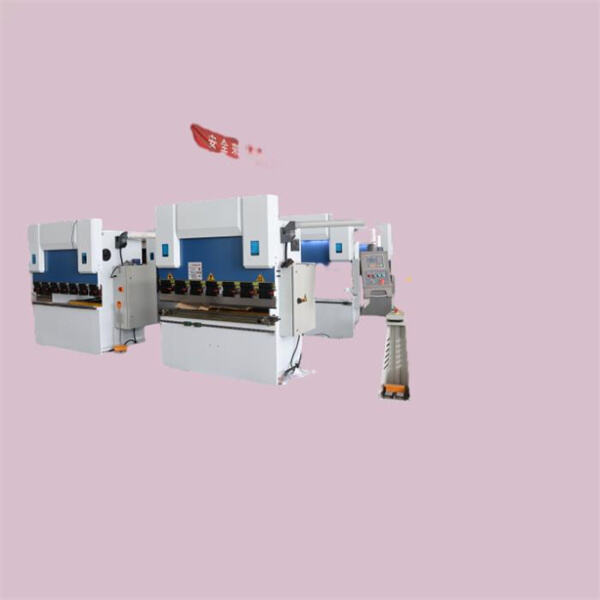

Computer numerical control bending is abbreviated as CNC bending. This means that the bending of the metal is computer-controlled. The material is in a press brake between a punch and die on a CNC bending machine. The computer then determines how hard the metal is pressed, causing it to curve into the shape we want. It is a highly accurate process and very effective for complex shapes.

CNC Bending in Metal Work There are so many advantages to using CNC bending in metal work. One big advantage is how precise it is. The computerized workflow ensures that each bend is right, and that every bend is the same, ensuring high-quality production parts. CNC bending also helps to speed up parts because the computer can move fast. And, CNC bending can form complex shapes that may be difficult to achieve using other bending methods.

CNC bending is employed in a wide range of industries for different applications. Within the car industry, CNC bending is used to produce metal components for cars and trucks. In construction, CNC bending is used to produce metal beams and supports for buildings. CNC bending is employed in manufacturing to form parts for machines and equipment. Conclusion Overall, CNC bending is a helpful procedure that opens up all sorts of possibilities for creating many different types of metal parts.

There are a few things you will want to consider when selecting a CNC bending machine for your project. First, think about the size of the metal pieces that you’ll need to bend. Ensure the CNC bending machine is capable of handling the size of the parts. You should also consider how complex the shapes are you have to bend. There are machines that are best for simple bends and other that can manage more complex shapes. Lastly, figure out how many pieces you have to produce. Select a CNC bending machine that will accommodate your project requirements.

Here are a few tips for getting the best bends possible on your CNC. Step 1: Check your position on the CNC bending machine First, ensure that your metal is positioned properly on the CNC bending machine. This equalizes all the bends so they are equal and true. Second, re-measure before you launch the bending program. This will prevent the error and wrong bend mistakes. And lastly, take care of your CNC bending machine, so it can take care of you too- in producing high-quality parts.