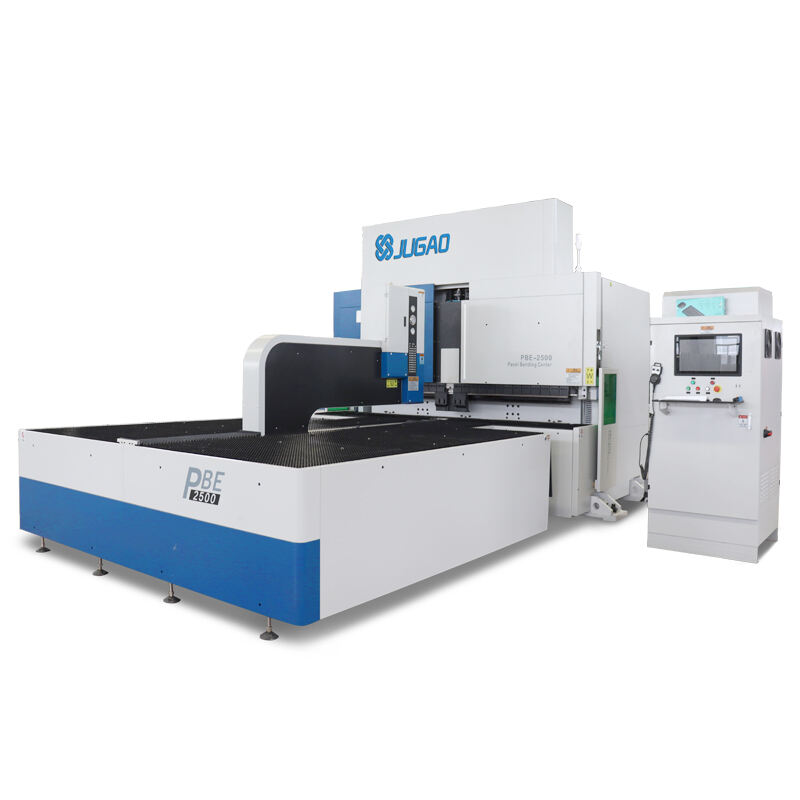

Bending flat sheets of metal into shapes is a fun (if challenging) activity. With a bending roll, you can create curves and circles of sheet metal of varying degrees to make such things as pipes and cylinders. In this guide, we'll learn about bending rolls and how they can be used to process metal.

If you are inexperienced in metal work, the bending rolls are a necessity. You use these machines to form metal sheets in order to bend and cut them into your desired shape. Bending rolls are available in a range of sizes, so it’s important to choose the right size for your project.

BENDING ROLLS There are many different types of bending roll. Each variety is created for different work. Bending Rolls for Plate are commonly used for hardened metal plate. Angle rolls form metal into corners and curves. Section bending rolls is used to curve or bend the metal components (beams channels, bars, etc).

Precision just really matters when you're doing metal. Bending rolls are used to bend sheet metal accurately. You need to use the correct bending rolls and set them properly so your shapes are spot on.

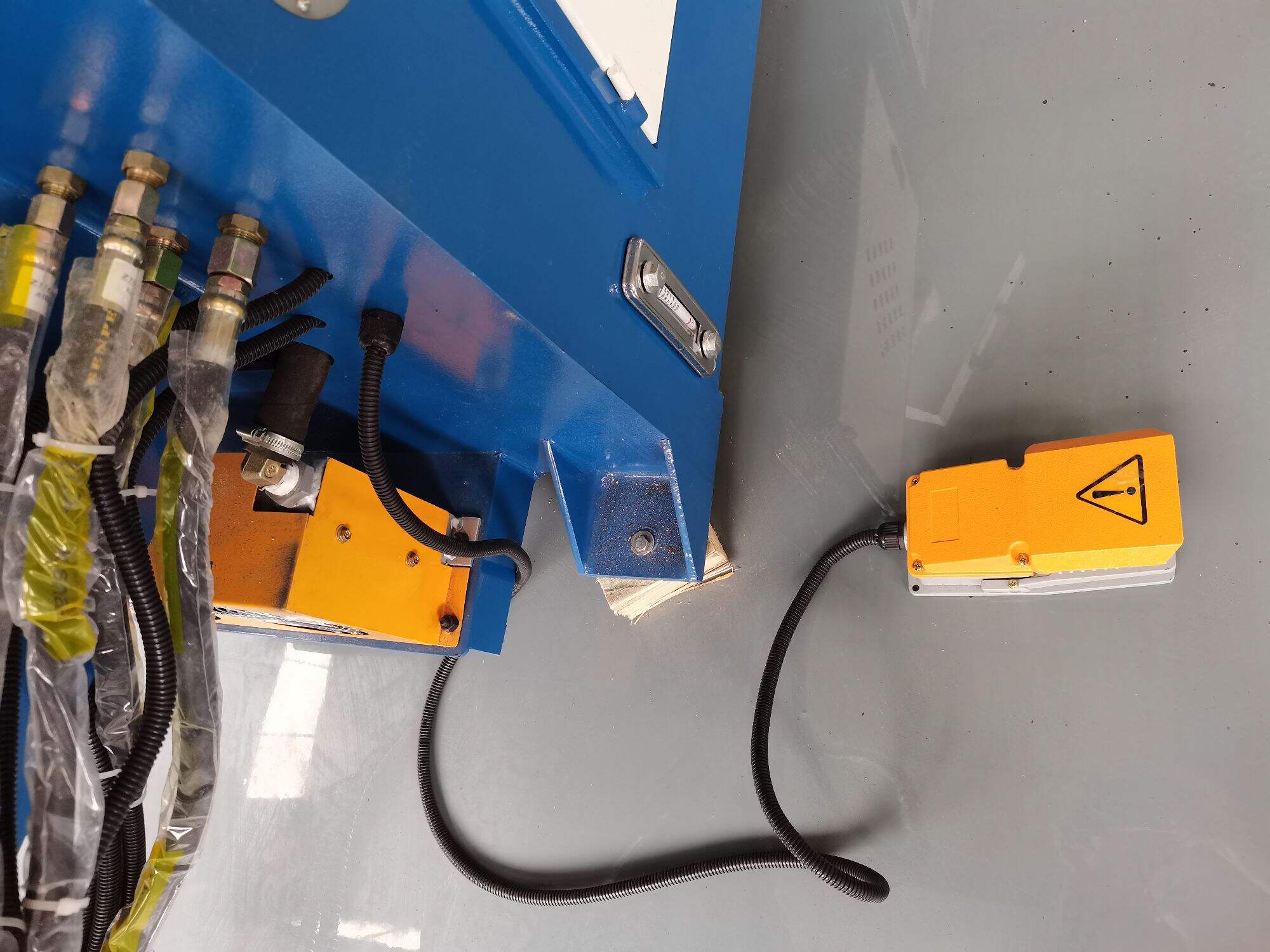

Always keep the safety in when operating bending rolls. And always use safety equipment, including gloves and goggles, to keep yourself safe. Read the manufacturers directions and don’t over do it with the machine.

When you are considering purchasing bending rolls for your project, there are several points to keep in mind. Consider the gauge and weight of the metal sheets you will be cutting and the cuts you want to make. “I would also recommend that you select your bending rolls from a reputable manufacturer to ensure that they perform as they should.