Strategic Customization Solutions for Press Brakes

Table of Contents

Core Elements of Press Brakes Customization

○ Precision Tooling Systems: Foundation of Process Flexibility

○ Intelligent Control Systems: Synergy of Accuracy and Efficiency

○ Back Gauge System Upgrades: Multiplier of Production Efficiency

○ Power and Stroke Extensions: Reliability for Heavy-Duty Processing

○ Safety and Compliance Configurations: Dual-Layer Risk Mitigation

Value Transformation of Customization in Production Systems

In-Depth Analysis of Key Questions

○ How to Achieve Millimeter-Level Precision Through Customization?

○ Which Configurations Maximize Downtime Reduction?

○ Feasibility and Implementation Paths for Power Upgrades

Conclusion: Strategic Significance of Customization Investment

Optimization Value of Customization for Press Brakes

In the metal fabrication industry, customized modifications to press brakes are a core strategy to overcome production bottlenecks. By precisely matching tooling configurations, intelligent control modules, and safety protection systems, enterprises can achieve a leap from basic processing to high-precision manufacturing. This article systematically analyzes five critical customization modules to empower production decision-makers in constructing optimal equipment configurations.

Core Elements of Press Brakes Customization

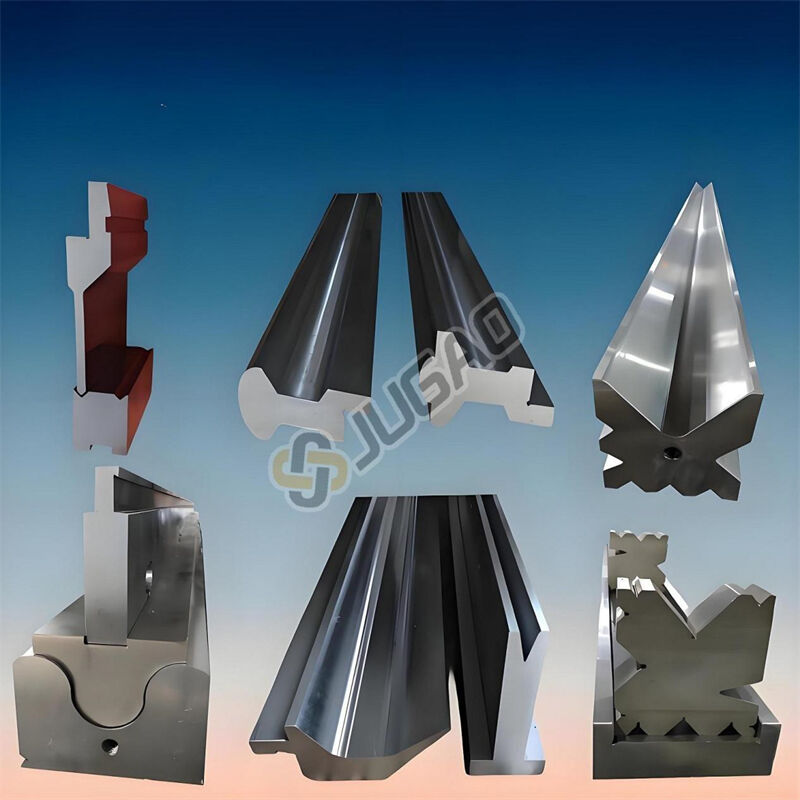

Precision Tooling Systems: Foundation of Process Flexibility

Tooling system customization directly impacts processing range and product accuracy. Recommended solutions include:

Modular Segmented Tooling: Enables rapid die changes for multi-specification workpiece demands.

Dynamic Compensation Mechanisms: Eliminates deflection deviations during long sheet metal bending.

Hydraulic Quick-Change Systems: Reduces die replacement time to 30% of traditional methods.

Industry practices show that professional tooling configurations can improve bending accuracy by 0.05mm and material adaptability by 40%.

Intelligent Control Systems: Synergy of Accuracy and Efficiency

Integration of CNC systems (e.g., DELEM DA-69T) enables:

3D Simulation Previews: Validates programs upfront, minimizing trial-and-error costs.

Process Parameter Databases: Automatically matches material properties with bending parameters.

Multi-Axis Synchronization: Coordinates back gauge and ram movements in real time.

A case study from an automotive parts manufacturer revealed 22% shorter processing cycles and scrap rates below 0.8% post-upgrade.

Back Gauge System Upgrades: Multiplier of Production Efficiency

6-Axis Servo Drive: Positioning accuracy of ±0.01mm.

Adaptive Compensation Algorithms: Real-time correction of sheet springback errors.

Memory Storage Function: Instant access to 200+ bending programs.

An appliance manufacturer achieved 35% higher daily output and sub-5-minute setup times after implementing multi-axis back gauge systems.

Power and Stroke Extensions: Reliability for Heavy-Duty Processing

For large structural components:

Hydraulic System Reinforcement: Maximum pressure up to 3000kN.

Extended Bed Design: Effective bending length expanded to 6m.

Dual-Cylinder Synchronization: Ensures pressure balance in ultra-long strokes.

An engineering machinery enterprise successfully fulfilled an order for 800 crane arms (25mm thickness) post-retrofitting.

Safety and Compliance Configurations: Dual-Layer Risk Mitigation

Essential configurations include:

Laser Scanning Protection: Safety light curtains with 0.1-second response.

Two-Hand Trigger Mechanism: Compliant with ISO 12100 standards.

Overload Self-Diagnostics: Preemptively detects hydraulic anomalies.

A stamping workshop reduced annual accident rates from 1.2% to 0.15% and obtained TÜV safety certification post-upgrade.

Value Transformation of Customization in Production Systems

Customization not only enhances individual machine performance but also reshapes production systems through:

1. Process Chain Integration: Seamless workflow from blanking to forming.

2. Flexible Production Capability: Rapid response to small-batch, high-variety orders.

3. Lifecycle Management: Data interfaces for MES system integration.

An aerospace component supplier compressed new product lead times from 45 days to 18 days via deep customization.

In-Depth Analysis of Key Questions

How to Achieve Millimeter-Level Precision Through Customization?

Implement closed-loop feedback control for real-time positional corrections.

Integrate temperature compensation modules to neutralize hydraulic oil thermal drift.

Conduct quarterly laser interferometer calibrations.

Which Configurations Maximize Downtime Reduction?

Deploy smart predictive maintenance systems (e.g., vibration monitoring).

Adopt standardized quick-change tooling systems.

Build preventive maintenance databases based on OEE analytics.

Feasibility and Implementation Paths for Power Upgrades

Assess frame rigidity compatibility with enhanced power requirements.

Phased implementation: Upgrade hydraulic pumps first, then reinforce frames.

Post-retrofit 72-hour continuous load testing is mandatory.

Conclusion: Strategic Significance of Customization Investment

Press brake customization is pivotal for manufacturers to achieve differentiated competitiveness. By strategically configuring functional modules, enterprises gain not only short-term efficiency but also agile manufacturing capabilities to navigate market shifts. Recommended implementation strategy:

1. Diagnose Bottlenecks: Use OEE analysis to identify improvement areas.

2. Modular Retrofitting: Prioritize high-ROI configurations.

3. Digital Integration: Connect machine data with management systems.

A precision sheet metal company boosted Overall Equipment Effectiveness (OEE) from 58% to 82% over three years, with a 14-month ROI period.