What key points should you consider when purchasing a press brake?

Purchasing a press brake is a technical decision that requires comprehensive consideration of many factors. To help you make the right choice, here are some key points to consider:

1. Determining the Part's Bend Radius

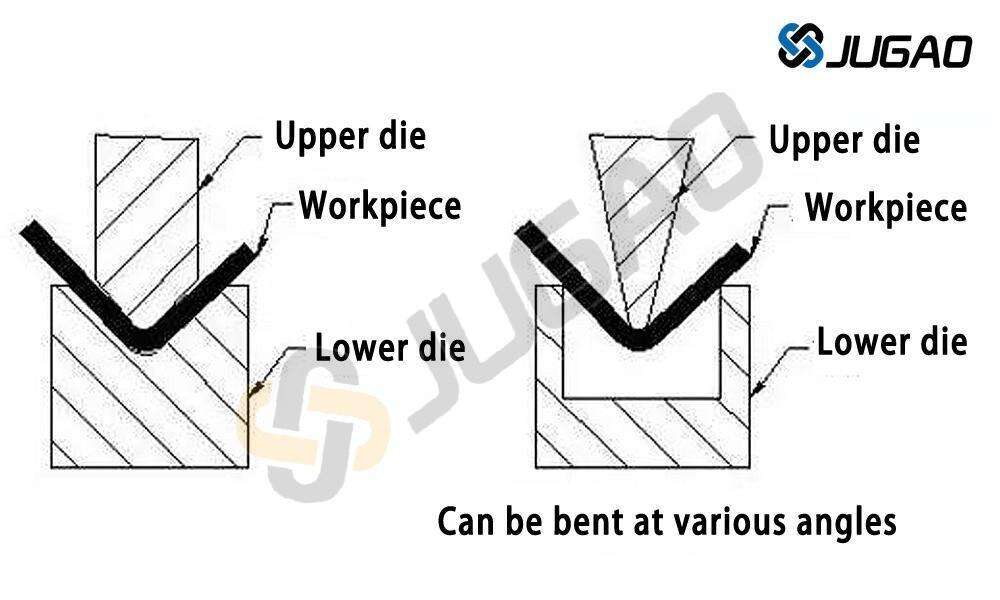

In free-form bending, the bend radius is typically 0.156 times the die opening width, which is generally recommended to be 8 times the material thickness. For example, using a 1/2-inch (approximately 12.7 mm) die opening on mild steel sheet results in a bend radius of approximately 0.078 inches (approximately 1.98 mm). In practice, pay attention to the clearance between the punch and die at the bottom of the stroke, allowing for adequate overbending to compensate for material springback and ultimately achieve a bend angle close to 90°.

If using the lower die forming method, the die angle is typically designed between 86° and 90°. At the end of the stroke, the gap between the punch and die should be slightly greater than the material thickness. Because die bending requires approximately four times the pressure of free-bending, springback-induced stress is significantly reduced, helping to achieve more accurate forming angles.

Imprint bending is similar to die bending, except that the punch tip is machined to the desired bend radius, and the clearance between the punch and die at the end of travel is less than the material thickness. By applying sufficient pressure to press the punch tip into the material, springback can be virtually eliminated.

When selecting equipment, it is recommended to target a bend radius greater than the material thickness and prioritize free-bending processes. Larger bend radii generally do not negatively impact workpiece quality or subsequent use.

2. Accuracy Requirements and Equipment Selection

Bending accuracy is a key factor in determining whether to choose a CNC press brake or a manual press brake. If angle accuracy of ±1° is required and no variation is permitted, a CNC machine should be preferred. CNC press brakes offer slide repeatability of up to ±0.0004 inches (approximately 0.01 mm), and when used with high-precision tooling, they can achieve extremely precise angle forming.

In contrast, the slide repeatability of manual press brakes is typically ±0.002 inches (approximately 0.05 mm). Even with high-quality tooling, the typical deviation is within ±2-3°. Furthermore, modern press brakes are often equipped with quick tool change systems, making them particularly suitable for small-batch, high-mix production.

3. Considering the practical impact of bend length

For example, to bend a 5×10-foot (approximately 1.5×3-meter) mild steel plate 90°, the press brake requires an additional force of approximately 7.5 tons to lift the plate, in addition to the basic bending force. The operator must overcome approximately 280 pounds (approximately 127 kg) of downward force. Processing such large workpieces often requires the assistance of multiple strong operators or even lifting equipment. Therefore, when selecting equipment, it is important to fully consider the range of common workpiece sizes, and press brake operations primarily focus on processing long edges.