The difference between plasma cutting machine and fiber laser cutting machine

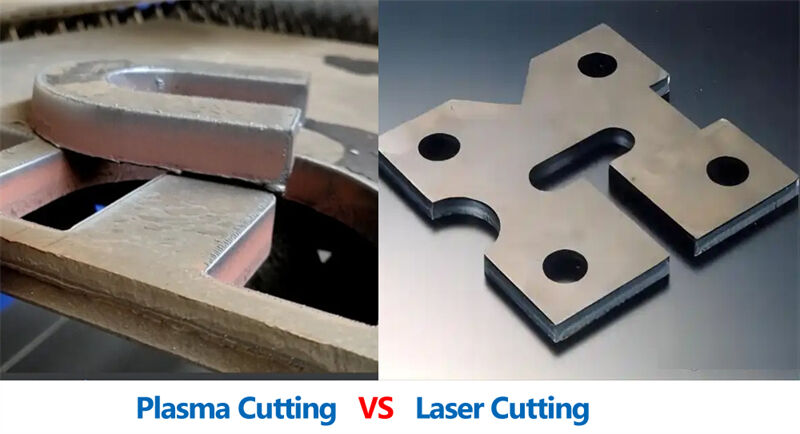

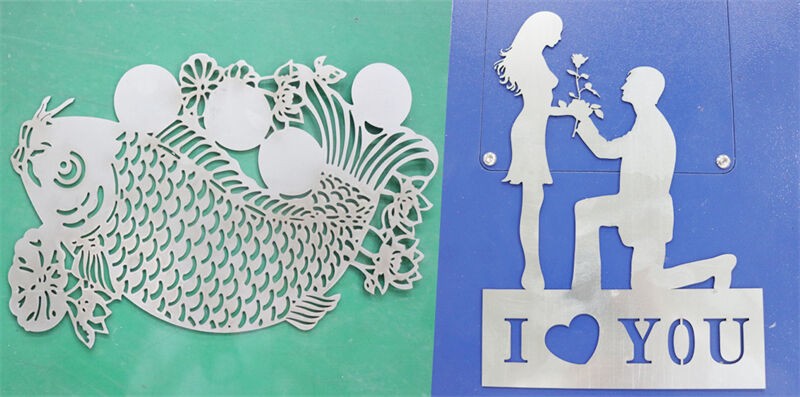

Fiber laser cutting, because it is an invisible beam that replaces the traditional mechanical knife, the mechanical part of the laser cutter head has no contact with the workpiece, and will not scratch the work surface during work; laser cutting is fast, the cutting is smooth and flat, and generally does not require subsequent processing; the cutting heat affected zone is small. The plasma machine is a thermal cutting equipment. Its working principle is to use the heat of the high-temperature plasma arc to partially melt the metal at the incision of the workpiece, and use the momentum of the high-speed plasma to remove the molten metal to form a processing method of incision.

Why does the plasma laser machine cut thicker than the fiber and cheaper than the fiber?

1. The surface of the plasma cutting machine is rough, it has advantages in cutting thick plates, and the price is low.

2. The cutting surface of laser cutting is smooth, and the plasma is rough, so people need to be sent to repair the burrs. The surface of laser cutting is smooth, the compensation precision is relatively high, and it is a little more expensive. In terms of cost, plasma is about 1/3 cheaper than laser.

3. The disadvantage of plasma is the slit width, which is about 3MM. The most important part of plasma is the power supply, which is equivalent to the laser of the laser cutting machine. Plasma consumes a lot of power, and the commonly used spare parts, electrode protection nozzles, are also quite expensive, especially electrode drilling.

4. Plasma is often used for thick plate cutting, while fiber laser cutting machines are often used for thin plate cutting. Plasma cutting requires people to repair burrs, while laser cutting can be formed in one step. No secondary processing is required.

Detailed distinction between laser cutting machine and plasma cutting machine:

1. Compared with plasma cutting, laser cutting is much more precise, with a much smaller heat-affected zone and a much smaller slit;

2. If you want precise cutting, small slits, small heat-affected zones, and small plate deformation, it is recommended to choose a laser cutting machine;

3. Plasma cutting uses compressed air as the working gas, high-temperature and high-speed plasma arc as the heat source, partially melts the metal to be cut, and blows away the melted metal with high-speed airflow to form a cut;

4. The heat-affected zone of plasma cutting is relatively large, and the slit is relatively wide. It is not suitable for cutting thin plates because the plate will deform due to heat;

5. The price of laser cutting machine is a little more expensive than that of plasma cutting machine.

The above is the full content of "What is the difference between plasma cutting machine and fiber laser cutting machine?" If you have any questions, please leave a message or consult customer service.