Precautions when laser cutting carbon steel plates

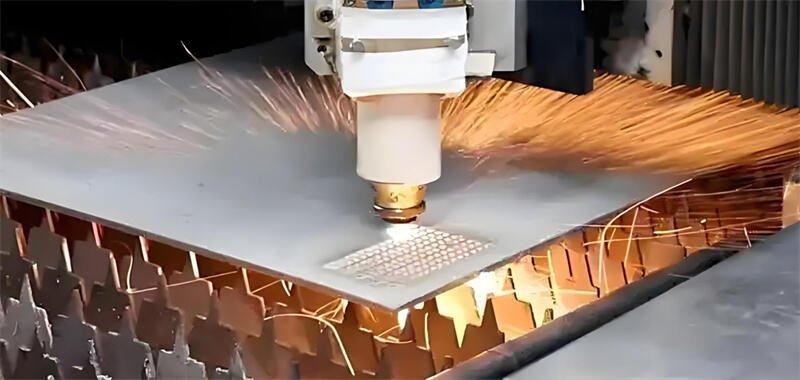

Laser cutting of carbon steel materials mainly uses fiber laser cutting machines. However, due to the high hardness of carbon steel, in order to avoid problems, the fiber optic equipment should be checked and maintained frequently. If problems occur during processing, the laser cutting machine should be checked from all aspects.

When all cutting conditions are normal, the cutting effect of carbon steel should be burr-free and the traction line should be consistent.

1. Burrs appear on the workpiece when laser cutting carbon steel

Possible reasons include:

(1) The laser focus position is offset. Perform a focus position test and adjust according to the offset of the laser focus;

(2) The output power of the laser is not enough. It is necessary to check whether the laser generator is working normally. If it is normal, observe whether the output value of the laser control button is correct. If not, adjust it;

(3) The cutting line speed is too slow. It is necessary to increase the line speed during operation and control;

(4) The cutting gas purity is not enough. It is necessary to provide high-quality cutting working gas;

(5) The instability caused by the long-term operation of the machine tool requires shutdown and restart.

2. Incomplete laser cutting

Reasons for incomplete laser cutting:

(1) The selection of the laser nozzle does not match the thickness of the processing plate, replace the nozzle or the processing plate;

(2) The laser cutting line speed is too fast, and the operation control needs to reduce the line speed.

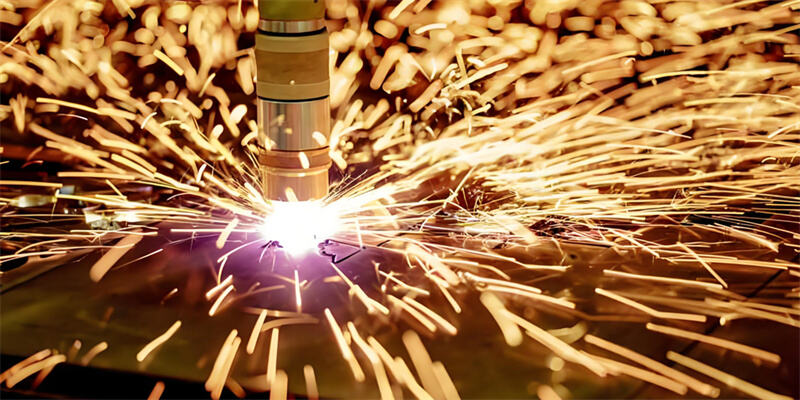

3. Abnormal sparks when cutting low carbon steel

When cutting low carbon steel normally, the spark beam is long and flat, with less forking. Abnormal sparks will affect the smoothness and processing quality of the cut section of the workpiece.

At this time, if other parameters are normal, the following situations should be considered:

(1) The laser head nozzle is seriously worn out and the nozzle should be replaced in time;

(2) In the absence of a new nozzle for replacement, the cutting working gas pressure should be increased;

(3) If the thread at the connection between the nozzle and the laser head is loose, the cutting should be stopped immediately, the laser head connection status should be checked, and the thread should be re-threaded.

How many watts of fiber laser cutting machine can cut 10mm carbon steel?

We recommend 3000W or 4000W fiber laser cutting machines. If the plates you cut are all below 10mm, you can consider a 3000W fiber laser cutting machine. The cutting speed of this wattage equipment can be guaranteed, and it is also easy to cut objects with precision requirements. If you are cutting large quantities of metal plates of about 10mm±2mm, you should consider a higher 4000W machine.