The Critical Role of Safety Light Curtains in CNC Hydraulic Press Brakes

In modern metal fabrication, CNC hydraulic press brakes represent both apowerful production tool and a significant safety challenge. Among the variousprotective measures available, safety light curtains have emerged as anindispensable component for operator protection. These advancedelectro-sensitive protective devices (ESPE) create an invisible safety barrierthat instantly halts machine operation when breached, preventing potentiallycatastrophic injuries.

How Safety Light Curtains Function

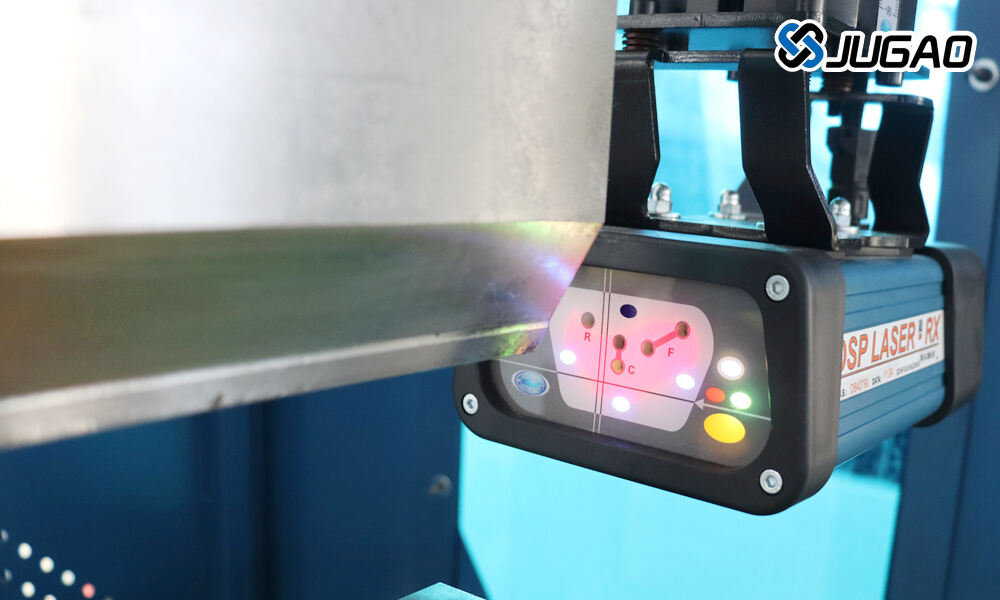

A safety light curtain system consists of two primary components:

1. Emitter Unit: Projects an array of synchronized infrared beams

2. Receiver Unit: Detects the integrity of the light beam pattern

When installed on a CNC hydraulic press brake, these components establish aprotective detection field around the hazardous area. The system continuouslymonitors this field at high frequency (typically 500-2,000 Hz). If any objectinterrupts the light beams - whether an operator's hand, tool, or other foreignmaterial - the system triggers an immediate safety response:

1. Sends a stop signal to the machine's safety-rated control system

2. Activates the press brake's dynamic braking mechanism

3. Maintains the stopped condition until manually reset

A safety light curtain is a kind of photoelectric protection device toavoidsafety accidents caused by operating workers or other people close totherunning machines.

Key Operational Advantages

Modern safety light curtains offer several critical benefits for press brakeapplications:

1. Enhanced Personnel Protection

Prevents crushing injuries during the bending cycle

Eliminates the need for physical guarding that can obstruct workflow

Complies with ISO 13855 safety standards for positioning

2. Improved Production Efficiency

Allows closer operator access than mechanical barriers

Enables faster setup and material handling

Reduces downtime compared to traditional safety systems

3. Advanced Safety Features

Self-checking circuitry for continuous reliability monitoring

Muting capability for automated material handling

Cascaded shutdown zones for different risk levels

Technical Specifications

| Parameter | TypicalValue | Importance |

| Resolution | 14-30mm | Determinesminimum object detection size |

| ResponseTime | <10ms | Ensurestimely machine stoppage |

| ProtectionHeight | 300-1800mm | Coversthe entire hazardous area |

| SafetyCategory | PLd/Cat.3(ISO 13849) | Meetsstringent safety requirements |

Implementation Considerations

Proper installation requires attention to several critical factors:

1. Positioning: Must maintain minimum safe distance per ISO 13855calculations

2. Alignment: Precoptical alignment ensures uninterrupted beam detection

3. Integration: Must interface with the machine's safety relay or PLC

4. Testing: Regular function checks including daily test cycles

Safety Light Curtains for CNC Hydraulic Press Brakes serve as a protectivebarrier, ensuring operator safety by detecting obstacles. They immediately stopthe machine if a person or object is detected, minimizing accidents andenhancing operational efficiency. The emitter sends light emissions to thereceiver on the other end and then the protective zone is formed. Once anobstruction (such as operator’s finger or other unexpected items) enters theprotection zone, the light curtain will immediately send a signal to thecontroller and stop the movement of the slider simultaneously.

Conclusion

Safety light curtains represent a sophisticated engineering solution thatbridges the gap between productivity and operator protection in CNC hydraulicpress brake operations. By implementing these systems, manufacturers canachieve:

Compliance with international safety standards (ISO 12100, ISO 13849)

Reduction in workplace accidents and associated costs

Improved operational efficiency through intelligent safety design

For optimal performance, always consult with safety specialists to ensureproper system selection, installation, and maintenance based on your specificpress brake configuration and operational requirements.