Professional Hydraulic Valve Group Maintenance Guide for Press Brakes

The hydraulic valve group is the core control unit of the hydraulic system.Its working state directly affects the equipment's operating efficiency andstability. Standardized maintenance can not only extend the service life of theequipment, but also prevent sudden failures and ensure production safety. Thefollowing is a professional-level maintenance operation process:

Comprehensive Maintenance Protocol

Pre-Maintenance Preparation

1. Safety Lockout Procedure

Engage main power disconnect

Install physical lockout devices with personal safety locks

Verify zero energy state by attempting to cycle machine

Release all hydraulic pressure from system

2. Workspace Setup

Clean, well-lit work area

Oil containment system (drip pans/absorbent materials)

Organized tool station with labeled containers

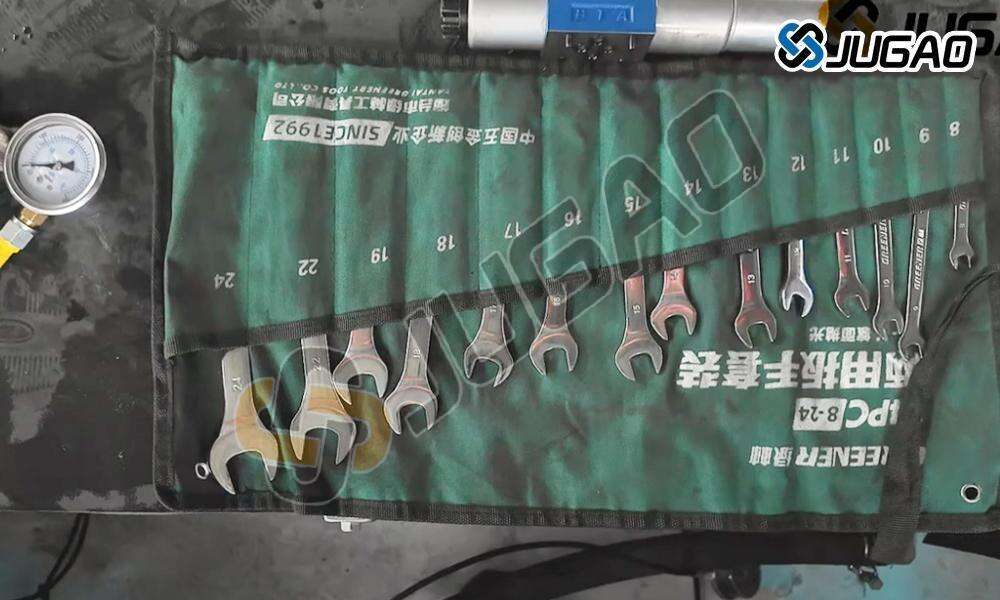

3. Required Tools & Materials

Metric hex wrench set (4mm-10mm)

Magnetic retrieval tools

Ultrasonic cleaning bath (optional)

Hydraulic seal kit (manufacturer specified)

Precision measuring instruments

Detailed Disassembly Procedure

Step 1: Valve Group Isolation

1) Locate primary hydraulic valve manifold

2) Tag and photograph all hydraulic connections

3) Drain residual hydraulic fluid into approved containers

4) Disconnect electrical solenoids (note wiring configuration)

Step 2: Systematic Disassembly

| ComponentLayer | FastenerSize | TorqueSpec | SpecialNotes |

| OuterCover Plate | M5Hex | 8-10Nm | Containsprimary O-ring |

| IntermediatePlate | M8Hex | 12-15Nm | Housesrelief valve spring |

| ValveCore Housing | M6Hex | 10-12Nm | Magneticretrieval recommended |

Step 3: Component Inspection

1. Valve Core Examination

Check for scoring/wear patterns (use 10× magnification)

Measure core diameter (tolerance ±0.01mm)

Verify smooth travel through bore

2. Spring Evaluation

Free length measurement

Compression test (compare to OEM specs)

Visual inspection for fatigue cracks

3. Seal Assessment

Hardness check (Shore A scale)

Cross-section deformation analysis

Surface imperfection detection

Advanced Cleaning Techniques

Mechanical Cleaning Process

1. Primary Debris Removal

Use lint-free swabs with mineral spirits

Magnetic particle extraction

Compressed air blast (regulated to 2 bar)

2. Precision Surface Treatment

Ultrasonic cleaning (20kHz, 60°C solution)

Micro-abrasive polishing (600+ grit)

Final solvent rinse (approved hydraulic fluid)

Contamination Analysis

Collect particulate samples for:

Metallurgical composition

Particle size distribution

Source identification (wear vs. contamination)

Reassembly & Testing Protocol

Precision Reassembly Steps

1. Component Lubrication

Apply manufacturer-specified assembly lubricant

Coat all sliding surfaces evenly

Protect seals with hydraulic fluid film

2. Torque Sequence

Follow star pattern tightening

Use calibrated torque wrench

Three-stage torque process (50%, 80%, 100%)

3. Alignment Verification

Dial indicator check (runout<0.02mm)

Solenoid actuation test (bench test)

Manual spool movement verification

System Commissioning

1. Pre-Start Checks

Verify fluid level and condition

Inspect for leaks (pressure-less)

Confirm electrical connections

2. Operational Testing

Low-pressure cycle test (25% rated)

Full stroke verification

Pressure ramp test (incrementally to 100%)

3. Performance Validation

Response time measurement

Pressure holding test

Cycle consistency evaluation

Maintenance Interval Recommendations

| Component | InspectionFrequency | ReplacementCriteria |

| ValveSpool | 500hours | >0.03mmwear |

| Seals | 2,000hours | Hardnesschange >15% |

| Springs | 5,000hours | >5%length deformation |

| EntireAssembly | 10,000hours | Cumulativewear indicators |

Troubleshooting Matrix

| Symptom | ProbableCause | CorrectiveAction |

| Delayedresponse | Contaminatedspool | Ultrasoniccleaning |

| Pressurefluctuation | Wornseals | Fullseal replacement |

| Externalleakage | Impropertorque | Re-torqueto spec |

| Erraticmovement | Springfatigue | Springkit replacement |

Advanced Maintenance Tips

1. Predictive Maintenance

Implement oil analysis program

Install particle counters

Trend performance data

2. Component Upgrades

Consider coated spools for extended life

Upgrade to high-cycle seals

Install quick-disconnect fittings

3. Documentation Standards

Maintain component history logs

Photograph critical stages

Record torque values

Safety Compliance Checklist

ANSI B11.3 machine safety standards

OSHA lockout/tagout requirements

NFPA hydraulic system guidelines

Manufacturer-specific warnings

Conclusion

This professional maintenance protocol extends valve group service life by40-60% while ensuring optimal press brake performance. Regular maintenancefollowing these procedures prevents 85% of hydraulic-related downtime. Alwaysconsult OEM manuals for model-specific requirements and keep detailed servicerecords for warranty compliance.