Matters needing attention after starting and starting the bending machine

Jan.25.2024

Matters needing attention after starting and starting the bending machine

PRESS BRAKE

#. Preparation before starting the bending machine

1. Complete the level adjustment of the bending machine.

2. Add reasonable hydraulic oil: The normal recommended model is #46 anti-wear hydraulic oil, and fill about 85% of the tank volume.

3. Connect a reasonable power cord: select the corresponding power cord according to the power of the equipment motor, and confirm whether the voltage of the machine tool is consistent with the actual voltage used.

4. Read the machine manual and operating system manual provided by JUGAO.

5. Connect the foot switch cable under the electrical box, and connect and fasten the foot switch in the direction of the aviation connector bayonet.

#. Precautions when starting up the bending machine and after starting up.

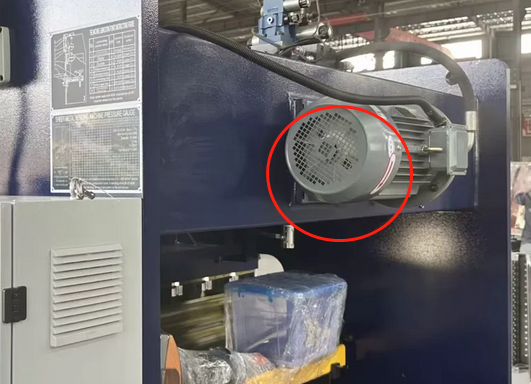

1. The direction of rotation of the motor oil pump: After completing the preparations before starting the machine. Turn on the power of the machine tool and all emergency stop switches. Press the start button of the oil pump and observe whether the motor rotates in the correct direction. Make sure that the rotation direction is consistent with the marked direction before continuing to start. If it is not consistent, just adjust the position of any two of the three wires of the power cord (rotating the direction of the motor can damage the oil pump).

2. Step on the foot switch and let the slider go up. Rotate jog or single state. Step on the foot switch to run the machine without load. Observe the no-load running state of the machine tool. The normal processing test can only be carried out after the machine tool runs stably.

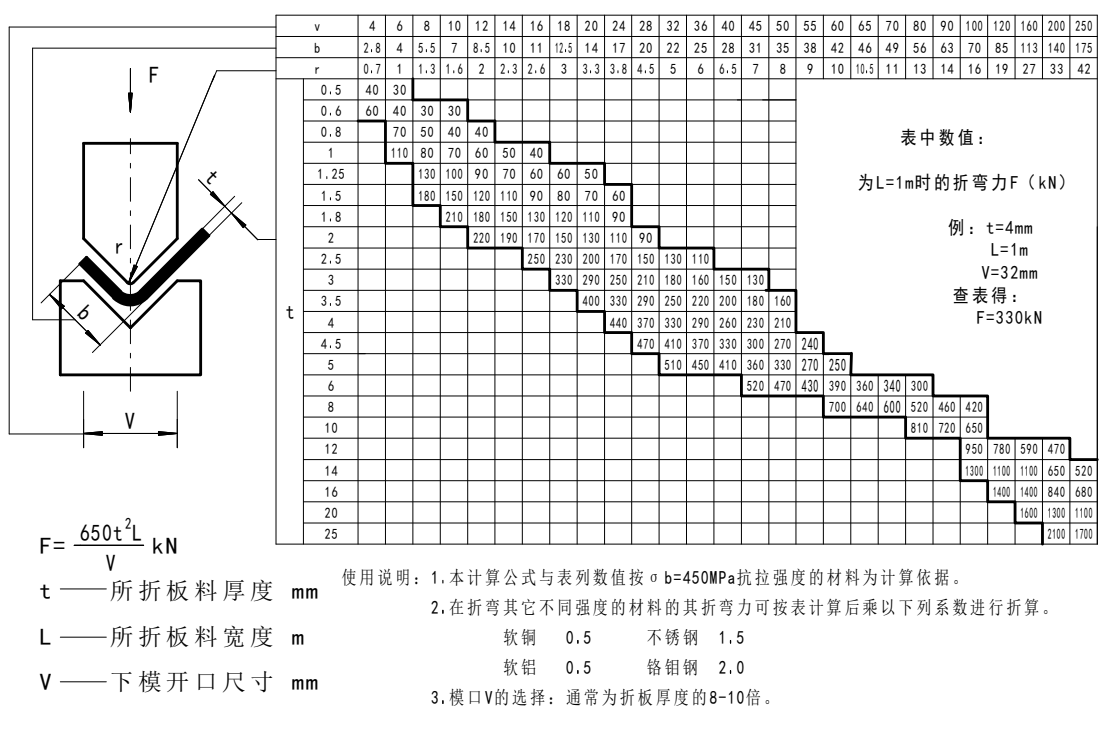

3. Select the appropriate notch according to the thickness of the plate to be processed (refer to the notch recommendation table). The normal recommended notch is 8 times the thickness of the plate. After adjusting the notch of the mold, it is necessary to ensure that the left and right gaps between the V groove and the upper mold are consistent. In addition, Y-axis (angle) parameters need to be set, and the setting values of different systems are different.

4. Initial test of sheet bending. After the setup is complete, do a preliminary test. It is recommended to carry out in jog mode. When bending 90°, it is found that the bending angle is less than 90° before pressurization, and pressurization cannot be performed, and the data needs to be corrected after returning. Otherwise, it is easy to damage the lower mold. In addition, short boards cannot be used to test the length of the board. Too short plate is easy to pressurize and concentrate, and crush the V groove of the lower die.

5. Save or record the data after the test is completed. It is convenient to process and call data later.

JUGAO Reminder: Read the instruction manual, system operation manual and start-up precautions before processing. Special reminder to pay attention to the damage of the oil pump and the damage of the V groove of the lower die!