Laser cutting machine selection and power drop processing method

How to choose a laser cutting machine?

1. Cutting format: It is the size of the equipment to be cut. You can choose the cutting format according to your factory area, the size of the material and the size of the material. .If your place is relatively large, or you want to put a whole sheet of paper on the cutting table, you can choose large-format cutting; if your place is relatively small, or the product cutting accuracy is relatively high, you can choose a small-format cutting table. Beam laser

2. Laser power: The stronger the power, the faster the cutting speed. If you are cutting sheets, or the material is thicker and has a higher density, choose high power; if the density of the cutting material is relatively low, or there is no requirement for the cutting speed, choose low power.

3. Equipment transmission: Common transmission methods include belts, gear racks, and lead screws. Leather is used for non-metallic cutting, gear racks are used for industries with faster cutting speeds, and screws are used for industries with higher cutting size requirements.

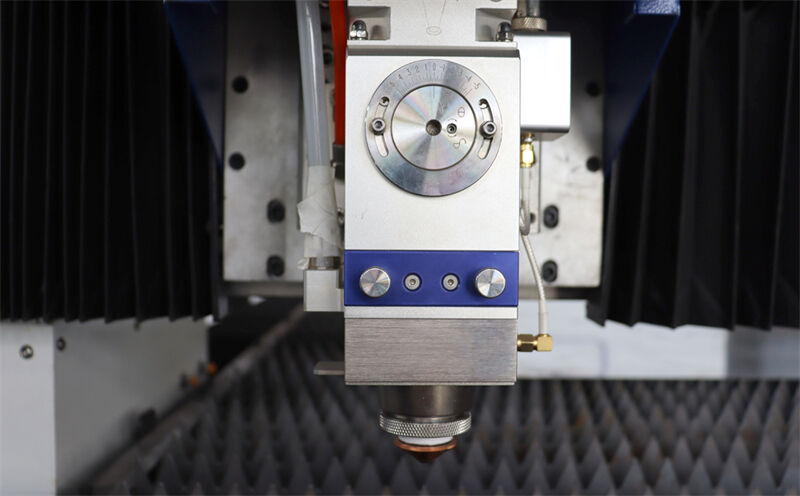

4. Light source selection: There are two light sources for laser cutting machines, one is carbon dioxide and the other is optical fiber; carbon dioxide is used for cutting non-metals, and optical fiber is used for cutting metals.

How to choose the power of a laser cutting machine?

Laser cutting machines can be divided into low, medium and high power according to power. For thin stainless steel and carbon steel plates, low-power fiber laser cutting machines can be used to cut well while ensuring a high cutting speed, which not only ensures work efficiency but also saves costs. Therefore, when purchasing a laser cutting machine, you must make a reasonable choice based on your material, material thickness, etc., and don't blindly pursue high power. Of course, if the plates you process include thick plates and thin plates, and the production capacity demand is very large, then a high-power laser cutting machine within your affordable price range is also a better choice. Because by properly adjusting the cutting speed, changing the auxiliary gas, etc., the high-power laser cutting machine can also control the cutting quality well when cutting thinner plates.

It is recommended that customers consider two points when choosing a high-power laser cutting machine.

Meet the customer's cutting requirements;

The price is within your own tolerance. The power of the laser cutting machine is one of the important factors you need to consider, but this does not mean that you should blindly pursue high power.

There are many factors to consider when purchasing a laser cutting machine. In addition to considering the maximum size of the workpiece being processed, the material, the maximum thickness to be cut, and the size of the raw material format, more consideration should be given to the future development direction, such as the maximum size of the workpiece to be processed after the technical modification of the product, the format of the material provided by the steel market, which is the most material-saving for your own product, the loading and unloading time, etc. Generally speaking, it is recommended to use a laser cutting machine for cutting metal materials such as carbon steel plates within 12mm and stainless steel plates within 10mm. The laser cutting machine has no cutting force and no deformation during processing: no tool wear, good material adaptability: whether it is simple or complex parts, it can be cut with laser for precise and rapid prototyping at one time: its cutting slit is narrow, the cutting quality is good, the degree of automation is high, the operation is simple, the labor intensity is low, and there is no pollution: it can realize automatic cutting and nesting, improve material utilization, low production cost, and good economic benefits.

How to repair the power drop of the laser cutting machine?

The laser cutting machine stands out in metal processing with its advantages such as high processing efficiency and good cutting effect. After using any equipment for a period of time, there will be some problems. For example, after a period of use, the laser cutting machine will have problems such as slow cutting speed and reduced cutting accuracy. There are many reasons for this.

What are the reasons for the power reduction of the laser cutting machine?

1. Power: After the machine is used for a long time, the power of the laser will decrease more or less, which will directly affect the cutting performance of the laser cutting machine;

2. Distance: The distance between the workpiece and the nozzle also affects the cutting effect of the laser cutting machine, so it is necessary to adjust the appropriate distance so as not to affect the cutting performance;

3. Position: The focal position directly affects the cutting progress. The diameter of the focal spot should be as small as possible, thereby producing a narrow slit. If the cutting performance decreases, adjusting the focal position is a good method;

4. Long-term overload production, lack of maintenance and improper operation by operators are all reasons for the decline in the performance of cutting equipment.

How to deal with the power reduction of the laser cutting machine

1. Pay attention to the maintenance of the machine at ordinary times. Long-term processing of the fiber laser cutting machine will cause wear of the parts, which will inevitably affect the cutting performance of the machine, so daily maintenance is very important. Daily maintenance can be carried out according to the daily maintenance table of the production company.

2. Standardize the operation of the machine. At present, the larger fiber laser cutting machine manufacturers will let customers arrange special personnel to receive training and train the machine operation process. Only after the training is qualified will they be arranged to work on the job. Special personnel operation is not only conducive to the normal operation of the fiber laser cutting machine, but also effectively avoids safety accidents.

Laser cutting machine is a technological revolution in sheet metal processing and is the "processing center" in sheet metal processing; laser cutting machine has high flexibility, fast cutting speed, high production efficiency, and short product production cycle, which has won a wide market for customers. The effective life of this technology is long. Most of the plates with a thickness of more than 2 mm abroad use laser cutting machines. Many foreign experts unanimously believe that the next 30-40 years will be the golden period for the development of laser processing technology. JUGAO CNC MACHINE has multiple models of laser cutting machines to meet the different needs of users.