How to Choose the Best Press Brake for Your Needs?

Table of Contents

Types of Press Brakes to Consider

1. Mechanical Press Brakes

2. Hydraulic Press Brakes

3. CNC Press Brakes

Core Features to Evaluate

1. Bending Capacity and Force

2. Backgauge System

3. Tooling Compatibility

Key Selection Factors

1. Production Volume

2. Budget Planning

3. Workspace Layout

FAQ Section

1. How to Determine the Right Tonnage?

2. Advantages of CNC Press Brakes

3. Are Toolings Universal Across Press Brakes?

Conclusion

Selecting the best press brake from a wide range of options can be challenging. Whether you work with thick or thin materials, or require high precision for complex bends, choosing a machine that aligns with your specific needs is critical. This guide will break down the essential factors to help you optimize productivity and meet your manufacturing goals.

Types of Press Brakes to Consider

Different press brake types cater to diverse production scenarios. Understanding their strengths ensures an informed decision.

Mechanical Press Brakes

Driven by a flywheel mechanism, mechanical press brakes excel in high-speed, standardized production. They offer rapid cycle times and low maintenance costs but lack flexibility. Ideal for repetitive, high-volume tasks with fixed processes.

Hydraulic Press Brakes

Hydraulic models dominate the market due to their versatility. With precise force control via hydraulic systems, they handle varying metal thicknesses and are perfect for small-batch, custom jobs. Their adaptability ensures consistent bending accuracy.

CNC Press Brakes

CNC press brakes leverage computerized automation for unmatched precision and efficiency. Pre-programmed parameters enable complex bends, making them indispensable in aerospace and automotive industries. While initial costs are higher, automation reduces labor errors and long-term operational expenses.

Core Features to Evaluate

Focus on these critical features when selecting a press brake:

Bending Capacity and Force

Tonnage and throat depth determine bending capacity. Higher tonnage accommodates thicker materials. Match tonnage to your typical material type (e.g., stainless steel, aluminum) and thickness to avoid underperformance or resource waste.

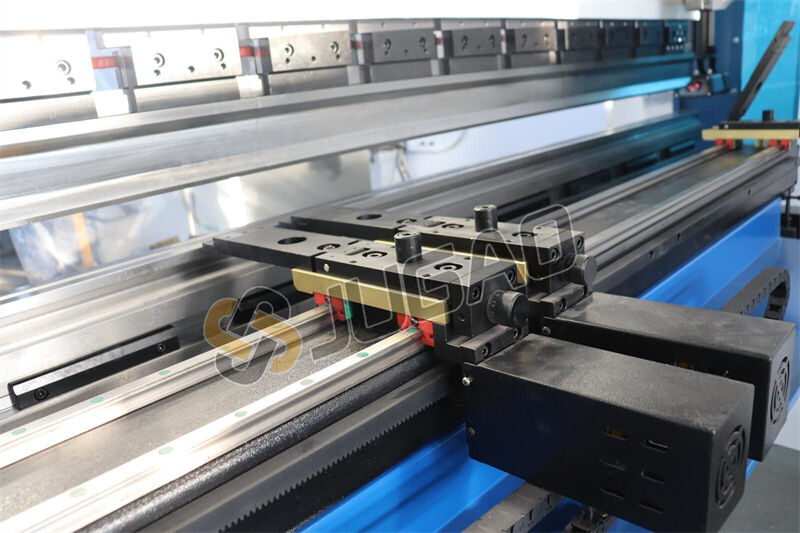

Backgauge System

A multi-axis adjustable backgauge ensures precise material positioning, especially for irregularly shaped workpieces. Prioritize models with user-friendly interfaces to streamline operations.

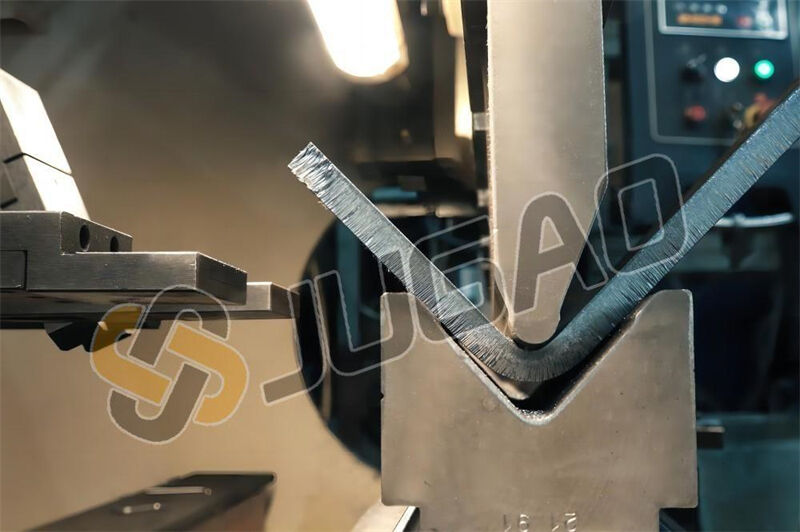

Tooling Compatibility

Tooling flexibility expands processing capabilities. Opt for machines compatible with diverse tooling (e.g., V-dies, R-dies) to handle varied tasks. Refer to the Tooling Selection Guide for detailed compatibility insights.

Key Selection Factors

Production Volume

1. High-volume production: Mechanical or CNC press brakes ensure speed and consistency.

2. Low-volume customization: Hydraulic models offer superior adaptability.

Budget Planning

3. High precision needs: CNC press brakes deliver long-term ROI despite higher upfront costs.

4. Balanced performance: Hydraulic brakes strike a cost-effective balance for SMEs.

5. Cost-sensitive scenarios: Mechanical brakes suit standardized processes with lower initial investment.

Workspace Layout

Match the machine size to your workshop. Compact C-frame designs fit tight spaces, while high-tonnage machines may require additional operational and maintenance clearance.

FAQ Section

How to Determine the Right Tonnage?

Calculate tonnage based on material thickness and type. For mild steel, required tonnage ≈ 8 tons per millimeter thickness (or ~20 tons per foot). Formula: Tonnage = Material Thickness (mm) × Material Factor × Bend Length (mm) / 1000.

Advantages of CNC Press Brakes

Automation and repeatability are key. Pre-set programs enable rapid parameter adjustments, minimizing human error—ideal for complex, high-volume production.

Are Toolings Universal Across Press Brakes?

No. Tooling compatibility varies by brand and model. Verify specifications to avoid additional costs post-purchase.

Conclusion

Selecting the right press brake requires balancing production needs, budget, and workspace constraints. Mechanical, hydraulic, and CNC models each suit specific scenarios. Align core features like tonnage and tooling compatibility with your operational demands. For personalized guidance, contact our technical team to tailor the optimal solution for your business.