Factors affecting laser cutting quality

The quality of laser cutting is determined by the dimensional accuracy of the

cut and the surface finish of the cut edge. The surface quality is typically

evaluated based on the following four criteria: the width and roughness of the

cut surface, the width of the heat-affected zone, the waviness of the cut

cross-section, and the presence of dross on the cut cross-section or lower

surface. The main factors influencing the surface quality of laser cutting are

as follows:

Laser Characteristics

The laser used for cutting must exhibit high beam quality. Since laser cutting is a thermal-based process, achieving a high power density and a fine cut requires a small focused spot diameter. Additionally, to ensure consistent cutting quality across different directions, the laser beam should possess excellent rotational symmetry around the optical axis, circular polarization, and high directional stability to maintain a stable focal spot position. Modern lasers should also feature continuous and high-repetition output with rapid switching capabilities to ensure high-quality cuts for complex contours.

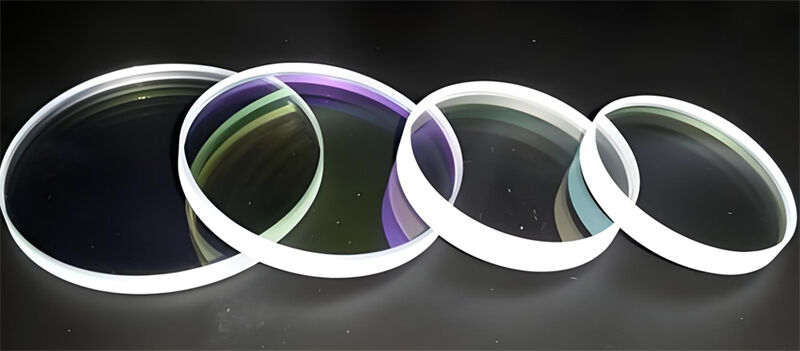

Focusing Lens and Material Thickness

The focal length of the lens should be selected based on the thickness of the material being cut, balancing the focused spot diameter and the depth of focus. For thicker materials, a longer focal length is preferable, while a shorter focal length is suitable for thinner materials. The focal spot position should be close to the workpiece surface, typically placed slightly below the upper surface of the material, approximately one-third of the material thickness.

Gas Flow and Nozzle

In laser cutting machines, the gas flow serves to expel molten material, protect the focusing lens, and even contribute some of the cutting energy. Gas pressure and flow rate are critical factors affecting cutting quality. Insufficient pressure may fail to remove molten material from the cut, while excessive pressure can create vortices on the workpiece surface, impairing the gas flow's ability to clear molten material. Practical experience has shown that nozzles with different designs can also significantly influence cutting performance.

Cutting Speed

The cutting speed depends on the laser power density, the thermal properties of the material, and its thickness. For a given set of cutting conditions, there is an optimal range of cutting speeds. If the speed is too high, the cut may be incomplete or leave residual slag. Conversely, if the speed is too low, excessive burning can occur, resulting in a wider cut and a larger heat-affected zone.

Cutting Path

For parts with complex contours or sharp corners, changes in acceleration can lead to overheating and melting at the corners, causing them to collapse. Therefore, optimizing the cutting path is an effective way to mitigate this issue.

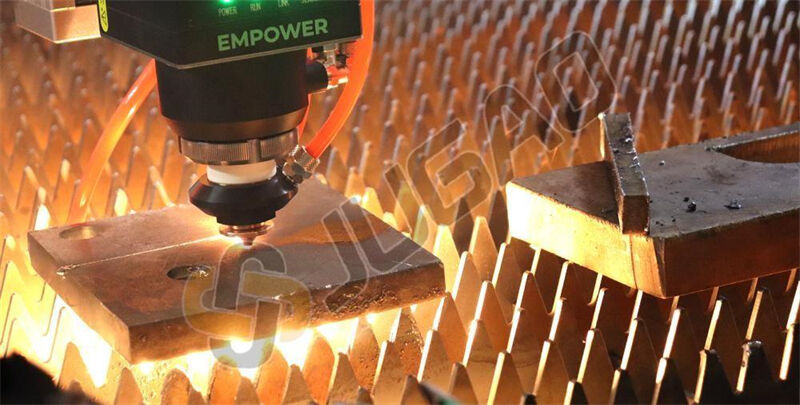

JUGAO CNC MACHINE's main products include laser cutting machines, CNC hydraulic bending machines, laser welding machines, shearing machines and pipe bending machines, etc., which are used in sheet metal processing, chassis cabinets, lighting, mobile phones, 3C, kitchenware, bathroom, auto parts machining and hardware industries.Welcome to consult online to learn more about the machine information.