Current Market Dynamics for Plate Rolling Machinery

Table of Contents

1.Key Industry Shifts Driving Demand

2.Customized Production and Small-Batch Orders

3.Renewable Energy and Infrastructure Expansion

4.Technological Evolution in Plate Rolling Systems

5.Automation and CNC Integration

6.IoT Connectivity and Predictive Maintenance

7.Sustainable Manufacturing and Energy Efficiency

8.Eco-Conscious Forming Operations

9.Processing Recycled Materials

10.Future Projections and Market Forecast

11.Emerging Market Opportunities

12.Modular and Intelligent System Designs

13.FAQs

Which plate rolling machine configurations dominate current demand?

How does automation impact ROI for rolling equipment?

Do energy-efficient machines justify capital expenditure?

14. Conclusion

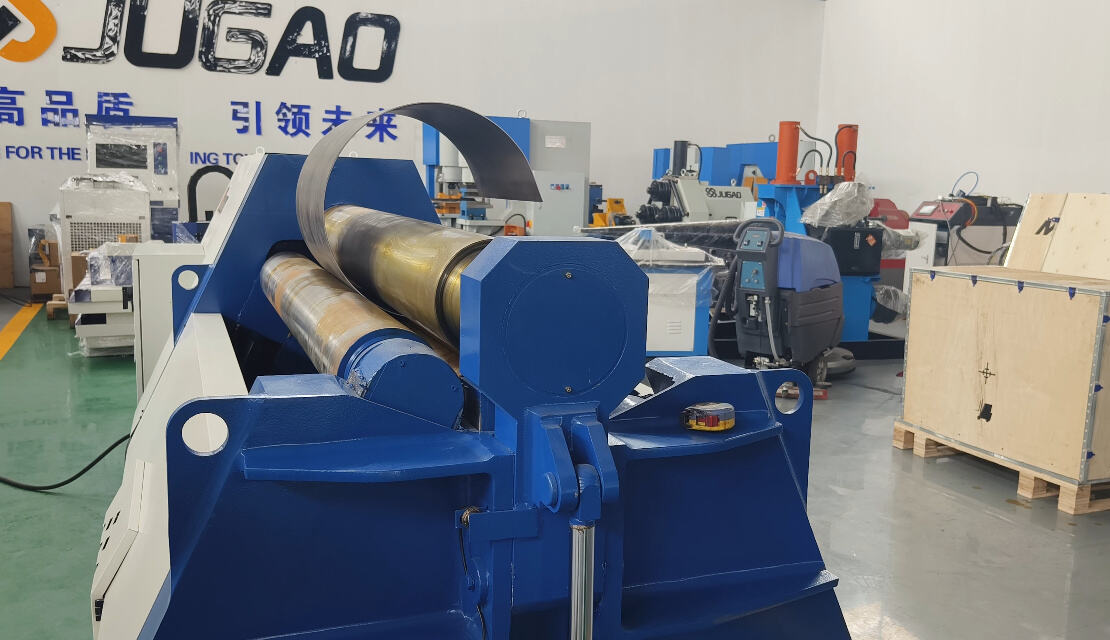

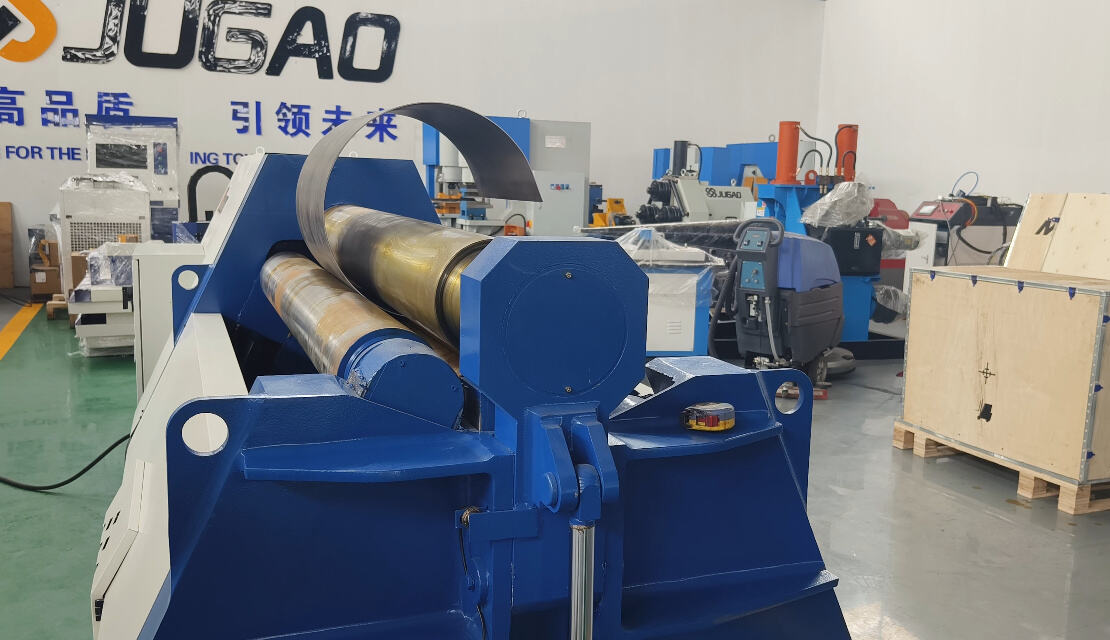

Introduction

For professionals evaluating capital investments in metal forming equipment, understanding Plate Rolling Machinery Market Dynamics is critical for strategic decision-making. Whether modernizing production lines or expanding capacity, anticipating industry evolution provides competitive advantages. This analysis examines technological advancements, key demand drivers, automation integration, and future trajectories for plate rolling systems. Those considering equipment acquisition or upgrades will gain insights for aligning strategies with market developments.

Key Industry Shifts Driving Demand

Customized Production and Small-Batch Orders

A defining trend is the surge in demand for tailored manufacturing solutions. Customers increasingly prioritize limited-run, high-tolerance components over standardized mass production. Consequently, equipment purchasers favor machinery featuring rapid tool-change systems, advanced PLCs (Programmable Logic Controllers), and intelligent material handling systems to accommodate flexible production requirements.

Renewable Energy and Infrastructure Expansion

The renewable energy sector—particularly wind tower fabrication and solar mounting structures—drives demand for heavy-plate rolling systems with capacities exceeding 100mm thickness. Concurrently, global infrastructure investments necessitate equipment capable of forming structural components for bridges, pipelines, and heavy machinery.

Technological Evolution in Plate Rolling Systems

Automation and CNC Integration

CNC-controlled plate rolling machines with automated feed systems, precision pre-bending functionality, and servo-hydraulic positioning have become industry standards. These systems deliver micron-level repeatability, reduced operator dependency, and accelerated cycle times. Modern equipment typically integrates with plant-wide ERP/MES platforms for operational synchronization.

IoT Connectivity and Predictive Maintenance

Leading manufacturers incorporate embedded sensors and IIoT (Industrial Internet of Things) analytics to continuously monitor bearing wear, roll deflection, and drive system performance. Predictive maintenance algorithms minimize unplanned downtime through data-driven component replacement scheduling.

Sustainable Manufacturing and Energy Efficiency

Eco-Conscious Forming Operations

Regulatory compliance and operational economics drive development of energy-optimized machinery. Standard features now include:

Variable Frequency Drives (VFDs) for motor control

Regenerative power systems capturing braking energy

Finite Element Analysis (FEA)-optimized frame designs

These innovations maintain forming tonnage while reducing energy consumption by 15-30%.

Processing Recycled Materials

Growing demand exists for machinery capable of forming high-tensile recycled alloys (e.g., EN 1.4021 stainless). This necessitates exceptional structural rigidity (≥300 MPa yield strength), adaptive crowning systems, and programmable springback compensation algorithms.

Future Projections and Market Forecast

Emerging Market Opportunities

Industrialization across Southeast Asia, MENA (Middle East/North Africa), and Sub-Saharan Africa will drive demand for robust, cost-effective plate rolls (3-roll initial pinch models predominating). Key requirements balance 12-25mm capacity with minimal foundation requirements.

Modular and Intelligent System Designs

Future developments will emphasize:

Modular architectures enabling retrofittable upgrades (auxiliary side supports, pressure-boosting packages)

Integrated edge deburring units

AI-powered diagnostic systems with remote OTA (Over-The-Air) updates

AR (Augmented Reality)-assisted maintenance interfaces

FAQs

Which plate rolling machine configurations dominate current demand?

CNC 4-roll plate bending machines with automatic workpiece alignment and real-time deflection compensation are preferred for aerospace and energy applications requiring ≤0.1mm/m straightness tolerance.

How does automation impact ROI for rolling equipment?

While increasing initial investment by 20-35%, automated systems reduce labor costs by 40-60% and material waste by 15-25%, typically achieving payback within 18-30 months through improved OEE (Overall Equipment Effectiveness).

Do energy-efficient machines justify capital expenditure?

Affirmative. Modern systems with regenerative drives reduce energy consumption by 25-40% versus conventional hydromechanical designs. For continuous operations, this translates to ≥$15,000 annual savings per machine at 0.12/kWh electricity rates.

Conclusion

Navigating Plate Rolling Machinery Market Dynamics enables strategic advantage. Investments in automation, sustainable technologies, and application-optimized equipment position enterprises for evolving industrial requirements. When considering plate rolling system acquisition or modernization, consult JUGAO engineering specialists for:

Application-specific machine specifications

ROI analysis with operational cost modeling

Integrated plant automation solutions

Lifetime technical support programs

Contact JUGAO for comprehensive metal forming solutions engineered for precision, efficiency, and long-term productivity.