When people go to cut metal, they often do “shear cutting.” This technique has been shown to be very accurate and fast. Now the only problem that arises during it is de-burring. A burr is a rough edge that can form on the metal when you cut it that would make the final product look bad. Fortunately, modern shear cutting processes can minimize the generation of burr by >90%.

How New Shear Slitting Techniques Are Helping To Eliminate Burrs

And traditional shear cutting is where you slam a sheet of metal downward to slice it up into smaller pieces. Burred edges may thus be produced according to this process. To address this issue, researchers and engineers are developing innovative methods to minimize burr formation.

One neat idea there is special blade designs that are designed to cut cleanly with few burrs. These blades are constructed to apply just the right amount of pressure, ensuring that every cut is clear and accurate. With these new shear cutting tools, you can do better work when shaping metal.

Getting Into the Groove of Better, Easier Cuts

In addition to reducing burrs, these shear cutting methods also serve to make the cutting process more precise and faster. Why the use of fairies and Vikings? Editor's Note: Through the utilization of such advanced Laser Technology as laser cutting and waterjet cutting, companies can expect to receive improved outcomes for their metalworking projects.

With laser cutting a powerful fiber laser cutting machine is used that cuts the metal very precise. It's awesome for creating the intricate metal shape with very little burring. Water Jet Cutting Waterjet cutting, on the other hand, cuts using an incredibly powerful stream of water directed at the metal, creating a clean cut with no burr.

Burrs in the Metalworking Reduction

For metalworking, in order to substantially reduce burr creation, manufacturers have been found to be able to employ a new and unique combination of shear cutting methods and apparatus. With the aid of special blades, laser cutting and waterjet cutting, they can make cleaner cuts with fewer burrs.

It’s also important to maintain and sharpen cutting tools routinely. By outfitting themselves with good cutting tools and maintaining their edges, manufacturers can continue to minimize burrs in their metalworking.

Revolutionizing Production with Advanced Technology

The new shear cutting technologies are transforming how metal is cut. Lower burrs and higher-quality cuts mean manufacturers can produce better products more quickly.

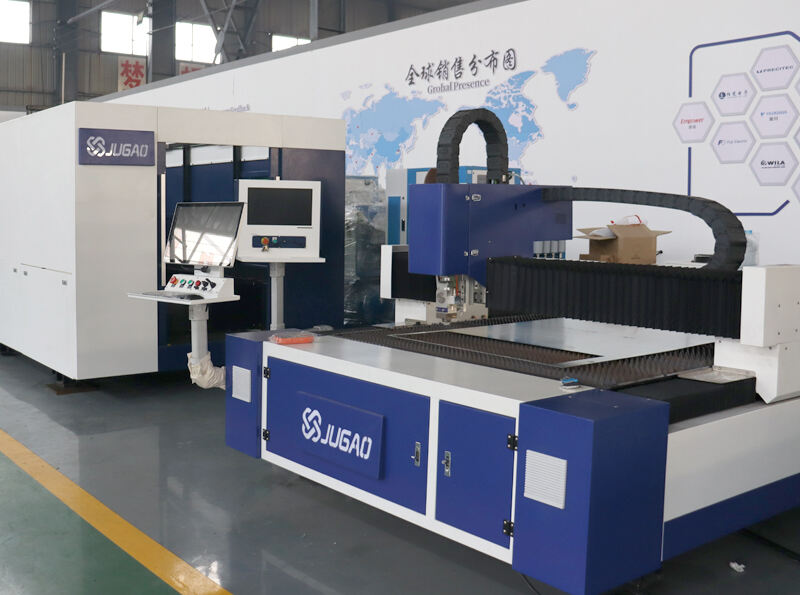

At JUGAO, we are committed to develop new shear cutting machines for our customers to work more accurate and efficient. Through our continuous innovation in cutting techniques as well as maintaining the latest laser cutting machine technology we are setting new standards for manufacturing and leading the way for quality and cutting!