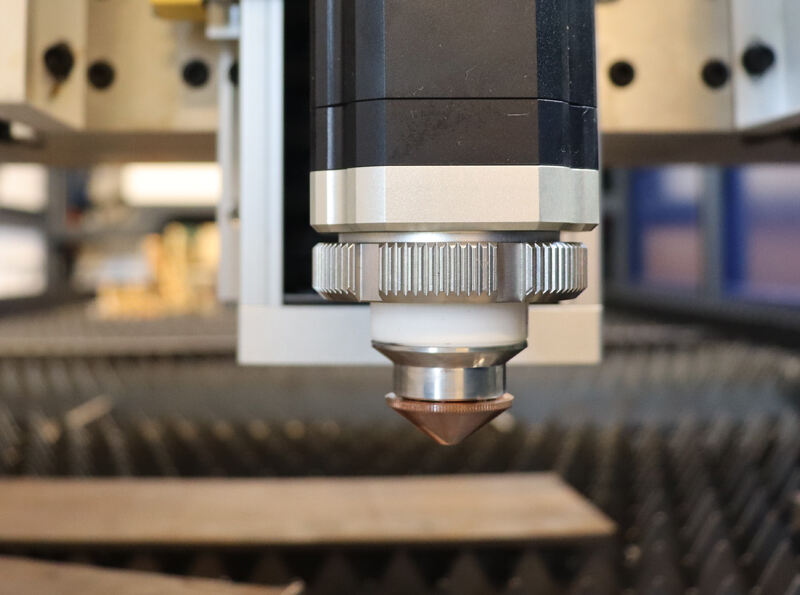

The spacing of the laser nozzles is also of great significance to the quality of the cuts you get from your laser metal cutting machine. How the machine cuts is part due to the space between the nozzles. In this article, we'll examine: Why Nozzle Spacing Is Important for Making Accurate Cuts How Varying the Nozzle Spacing Leads to Better Cut Quality We will also take a look at nozzle spacing and how it relates to smooth edges, the optimum spacing for different materials, and how it contributes to waste and overheating reduction.

The Importance of Laser Nozzle Spacing for Cutting Efficiency:

Precision is key when working with a laser cutter. How far apart the nozzles are placed may actually determine just how well the machine worked in terms of cutting through a material. If the nozzles are too close to each other the laser beam can overlap, and the edges may come out rough and not cut straight.” If the nozzles are too spread apart, the cut could go too shallow, in which case it might not cut all the way through.

To make accurate cuts, the right distance between the nozzles is essential. This is to ensure that the laser beam will be evenly distributed across the material, producing clean and precise cuts each time.

How Variations in Nozzle Spacing Can Affect Cut Quality:

With adjustment of the spacing between nozzles, operators can improve cuts. When the nozzles are closer together, the laser welder prices beam also intensifies, allowing for faster and more precise cuts. It can help prevent the material from getting too hot and burning, resulting in a cleaner cut if the nozzles are further apart.

Operators will need to test and tinker with nozzle to nozzle distance to optimize for their material. Even small adjustments will make the cut quality better and achieve the outcomes they desire.

The Relationship between Nozzle Spacing and Edge Smoothness:

It’s also the space between the nozzles that determines how neat the edges of the cuts will be. Tight spacing can produce clean edges, while loose spacing may result in ragged edges.

Optimal Nozzle Spacing for Various Materials

For cutting materials that requires a smooth, clean edge, operators should consider the distance between nozzles. By varying the space, they can achieve exactly the smoothness they desire, and boost the quality of the cuts.