Bending radius

What is the bending radius of sheet metal?

The bending radius of sheet metal is a value required in sheet metal drawings, but it is difficult to determine the specific value in actual processing. It has a certain relationship with the material thickness, the pressure of the bending machine, the width of the lower die groove of the bending die, etc.

So how to get the radius of sheet metal bending?

1. Sheet metal thickness

First of all, the thickness of sheet metal is a major basis for determining the bending of sheet metal.

Generally, when the thickness of the plate is not more than 6mm, the plate thickness can be directly used as the bending radius inside the plate when bending.

When the plate thickness is greater than 6mm and less than 12mm, the bending radius inside the plate is generally 1.25 to 1.5 times the plate thickness. When the plate thickness is not less than 12mm, the bending radius inside the plate is generally 2 to 3 times the plate thickness.

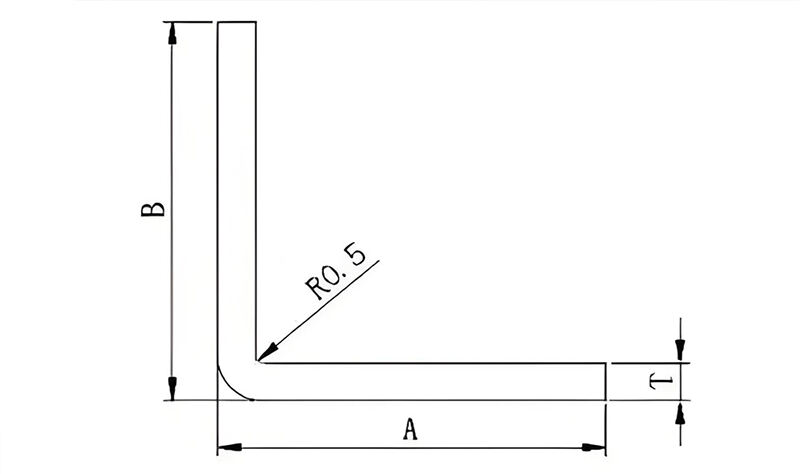

When the bending radius is R=0.5, the general sheet metal thickness T is equal to 0.5mm. If a radius size greater than or less than the plate thickness is required, a special mold is required for processing.

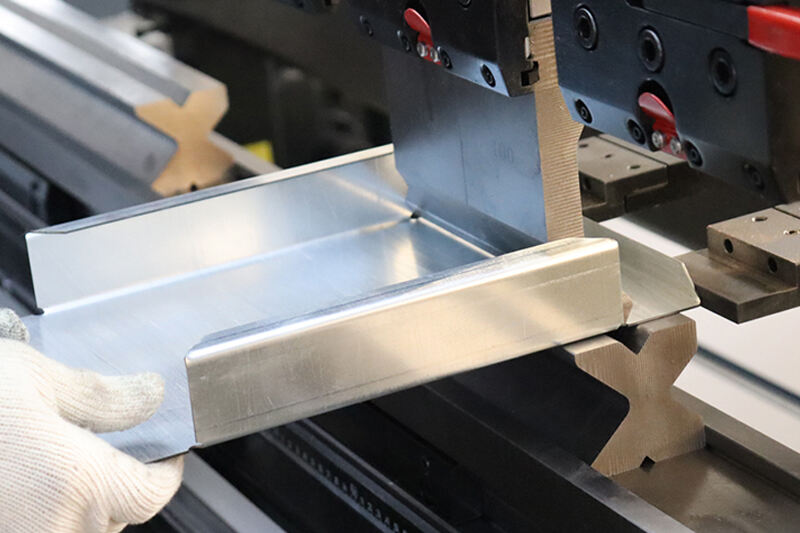

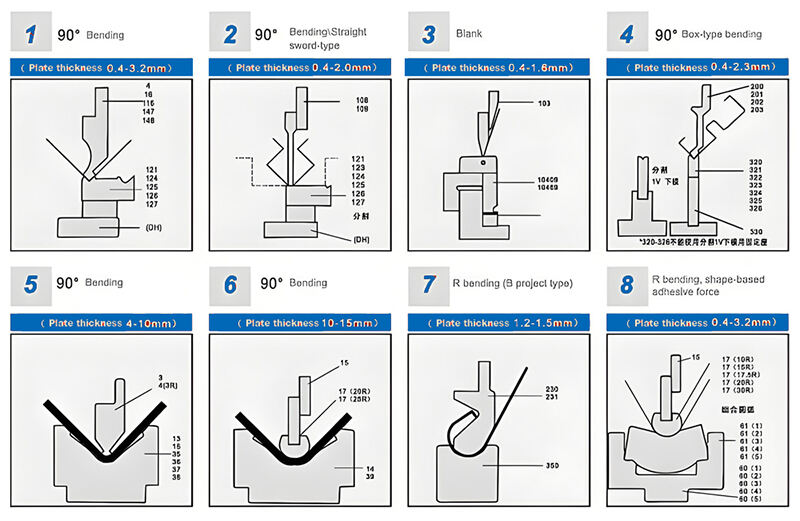

When the sheet metal drawing requires the sheet to be bent 90°, and the bending radius is particularly small, the sheet metal should be grooved first and then bent. Special upper and lower dies of the bending machine mold can also be processed.

2. The width of the lower die groove of the bending mold

At the same time, through a large number of experiments in sheet metal processing, it is found that the width of the lower die groove of the bending mold has a certain relationship with the size of the bending radius.

For example: 1.0mm sheet is bent with an 8mm groove width, so the bending radius pressed out is R1 under ideal conditions.

If a 20mm groove width is used for bending, since the upper die moves downward during bending, the depth of the stretched sheet reaches a certain angle.

Then we know that the area of the 20mm wide groove is larger than that of the 8mm wide groove. When bending with a 20mm wide groove, the stretching area also increases and the R angle also increases.

Therefore, when there is a requirement for the bending radius of the sheet without damaging the bending machine mold, we try to use a narrow groove for bending.

Under normal circumstances, it is recommended to operate according to the standard ratio of plate thickness to slot width of 1:8. The minimum ratio should not be less than 1:6. Sheet metal bending can be slightly smaller, but not less than 1:4.

Suggestion: If the strength allows, it is preferred to use the method of planing grooves first and then bending to make a small sheet metal bending radius.