Basic knowledge of bending molds

1. Bending upper die

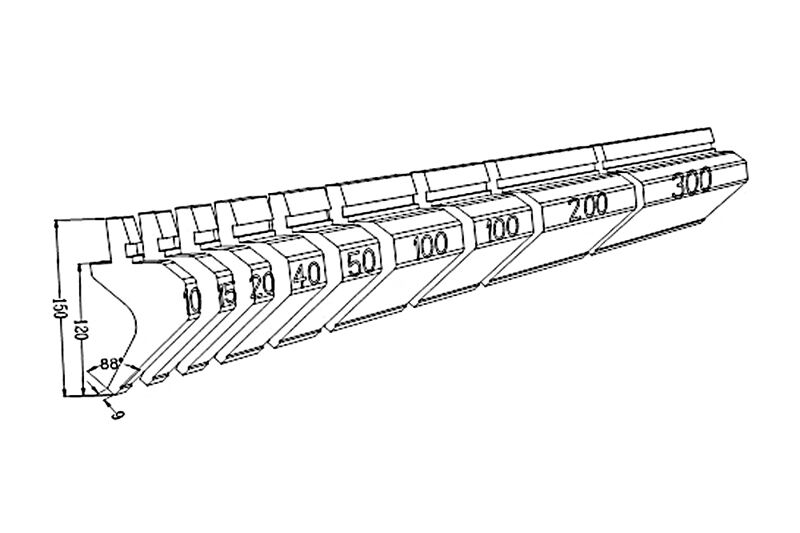

The upper die is also called a folding knife. It is divided into two types: integral and split. The length of the integral upper die is 415mm and 835mm. The length of the split type is 10, 15, 20, 40, 50, 100 (left ear), 100 (right ear), 200, 300 (mm); the split die can be combined into different bending lengths.

The upper die is divided into four types: straight knife, curved knife, arc knife, and special knife.

(1) Types and processing characteristics of straight knives

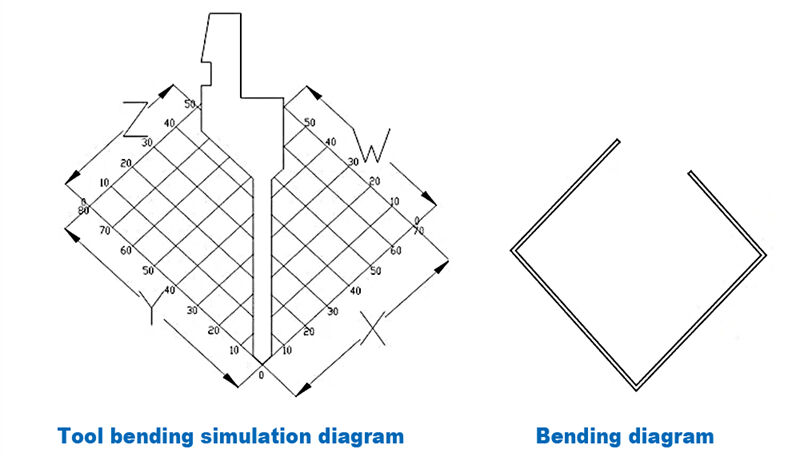

Suitable for bending symmetrical products, the front and rear directions can be avoided, the tool thickness is 6mm, so the bending opening can be as small as 6mm.

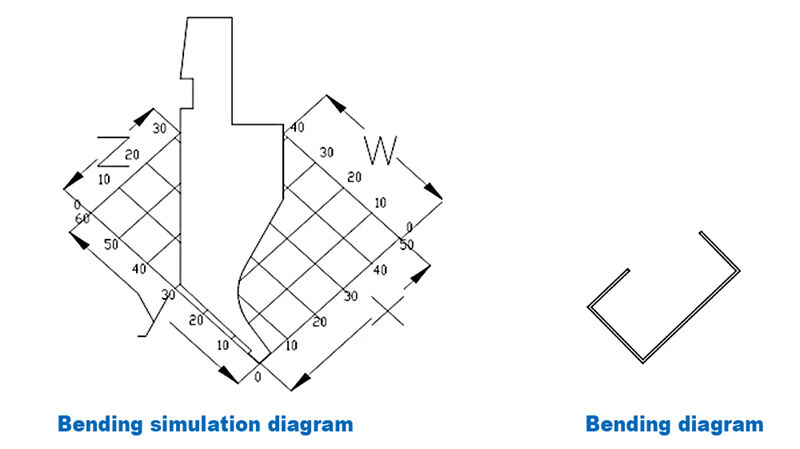

From the tool bending simulation diagram, it can be seen that the front and rear directions of the tool can be avoided, but the length of Z and W is smaller than the length of X and Y. The tip angle of this tool is 88 degrees, and the tip R angle is 0.2. In addition, tools with tip angles of 30 degrees and 45 degrees are commonly used.

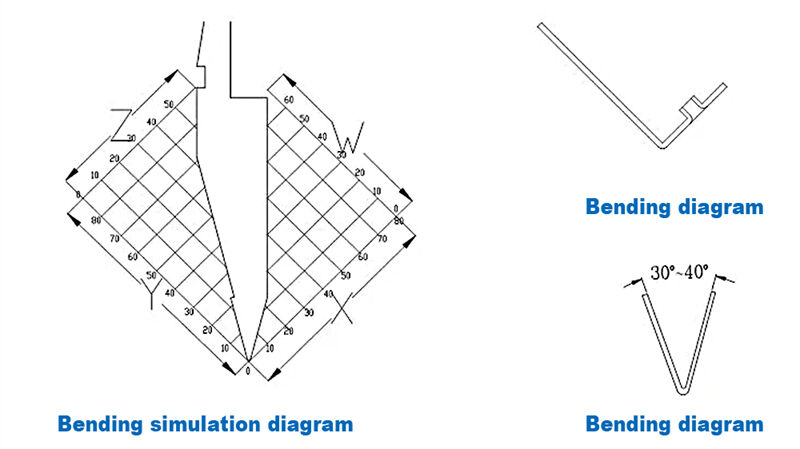

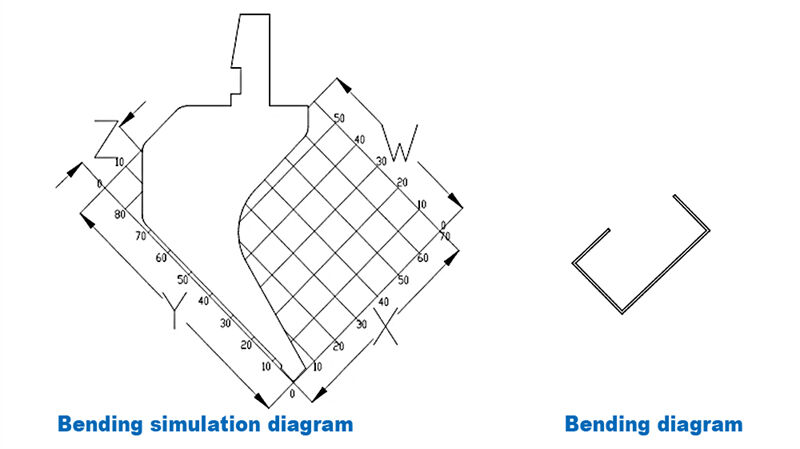

The tip angle is 30 degrees, and the tip R angle is 0.67, so the bending angle can be 30 to 180 degrees. The small angle of the tip of the tool can be used to avoid the bud hole or nut, etc. It can also be used as a deep insertion mold, and the tool can avoid the front and back.

(2) Types and processing characteristics of curved knives

During the bending process, the tool mainly uses the avoidance in the W direction. When X>15MM, the avoidance effect becomes worse and worse. When Y>30, the bending condition is met, otherwise it will hit the back of the knife. This type of tool is commonly known as a small curved knife.

During the bending process, the tool mainly uses the avoidance in the W direction. When X>25MM, the avoidance effect becomes worse and worse. When Y>75, the bending condition is met, otherwise it will hit the back of the knife. This type of tool is commonly known as a large curved knife.

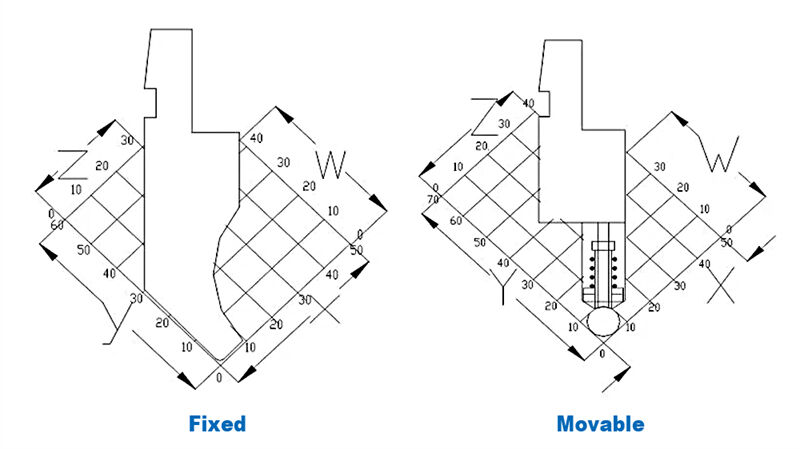

(3) Types and processing characteristics of arc cutters

Arc cutters are divided into fixed and movable types. Arc cutters meet different arc bending processing conditions by replacing round bars. When the X dimension of a fixed arc cutter is >10MM, its avoidance effect is the same as that of a small curved cutter. The general selection standard for the lower die V-groove is the diameter of the arc plus two plate thicknesses.

(4) Types and processing characteristics of special tools

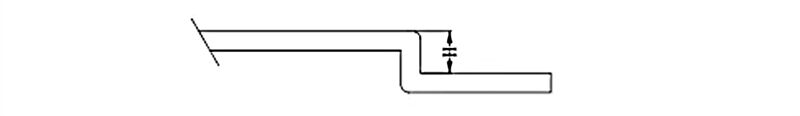

The special tools of the folding machine include step-down dies, flattening dies and some special-shaped bending upper dies.

a: The existing step-down dies are divided into two types: 415mm and 835mm. The size specifications of the segmented shape are consistent with the specifications of the tool segmentation. The bending shape of the forming diagram specifications is formed. However, when the thickness of the plate is thicker, such as T=2.0, considering the severe indentation and the limitations of the mold itself, it will be difficult to form.

b: The upper mold of the flattening mold is a flat mold, and the lower mold can be replaced by an ordinary bending lower mold, but avoid the V groove. It is mainly used for processing methods such as dead edge flattening and riveting nuts.

2. Bending lower mold

The lower die of the folding machine includes bending lower die, insertion lower die, flattening lower die, etc.

(1) Bending lower die

The selection of the bending lower die of the folding machine is mainly based on the plate thickness of the processed product. At present, the lower die selection standard of Yixin Company is 6T, which is used as the standard for on-site operations unless there are special circumstances. When large V or small V groove processing is required due to processing restrictions, the bending coefficient needs to be adjusted accordingly.

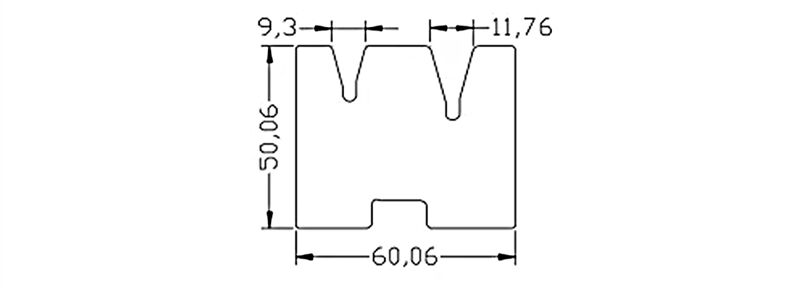

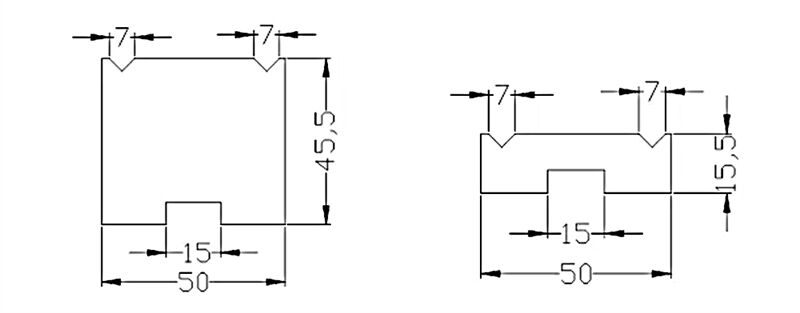

Mold analysis: The figure shows one type of lower die. The types of V grooves mainly include 4V, 6V, 7V, 8V, 10V, 12, 16V, 25V and some special large V groove bending tools. This type of bending lower die is mainly divided into 46 high and 26 high according to the height.

(2) Insertion depth lower die

Mold analysis: The figure shows one of the insertion depth lower dies. The types of V grooves mainly include 4V, 6V, 8V, 12 and some special insertion depth lower dies. It is suitable for bending and inserting any angle between 30-180 degrees.