Steel plate rolling machines are enormous machines we use to shape steel. They’re like giant robots that can build whatever you want out of steel!

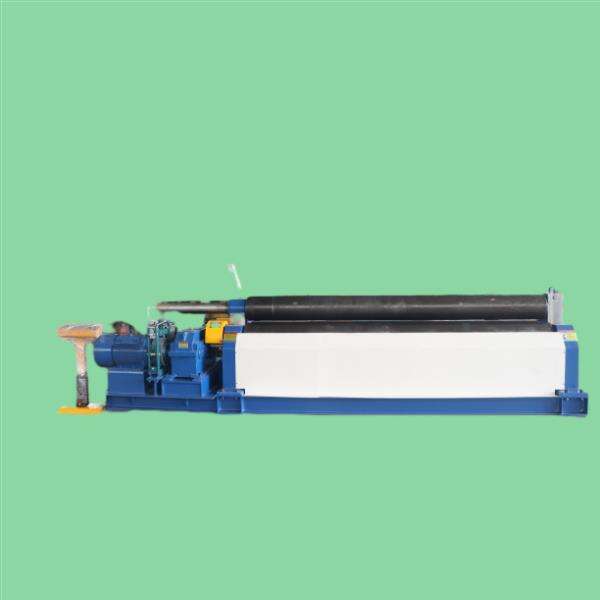

Plate bending rolls can ride the curve of the metal. They’ve got big rollers, which press down on the steel plates to bend them. Factories and workshops use the devices to fabricate things like pipes, tubes and cylinders out of steel.

There are lots of reasons why you would want to use a steel plate rolling machine. One is that it’s relatively fast and inexpensive. In place of hand-bending steel, a machine is faster and more accurate. There’s another reason, too: These machines can bend and cut very precisely and accurately, a useful feature when you’re trying to create something that needs to fit together perfectly.

One thing that many forget to consider is the size and diameter of the actual steel plates you will be working on. You may also want to think about how frequently you will be using the machine and the shapes you will be needing to cut. It’s wise to consult a machine expert, like those at JUGAO, to guide your search for the right machine for your requirements.

Maintaining a steel plate rolling machine Some of the rules in Maintaining a steel plate rolling machine.include: Taking care of a steel plate rolling machine is important so as to have it work well. You need to keep the machine clean and lubricate the moving parts to prevent rusting. It’s also wise to look for any loose bolts or screws, and tighten them if necessary. If you notice any issues, have it repaired as soon as possible to prevent further damage.

In technology, everything gets better, including steel plate rolling machines. Technological developments have enabled these machines to become more efficient and accurate. Some machines these days also come with computer controls that can make accurate bends and shapes at the push of a button. These advancements make it simpler for us to produce steel elements in a fast and precise manner.