In a modern world it's technology that helps things happen faster, more accurately, more efficiently. One of these engineering wonders that are changing the way things are made is the industrial laser cutter. The incredible piece of machinery utilises a high-powered beam of light to slice through materials with extremely high accuracy. Here’s a deeper dive into how industrial laser cutters are revolutionizing manufacturing

The main advantage of using an industrial laser cutter is that it significantly speed ups the production process while ensuring the accuracy of the work. Conventional techniques of cutting work may take time and/or may not give accurate results. Material Cutting: Speed and precision are the two key factors in the field of materials cutting, and industrial laser cutting machines process materials with both efficiency and precision, sparing valuable time and reducing waste. This means that products can be produced at faster speeds and with fewer mishaps, which means that companies have gotten more productive and more efficient in terms of costs.

Industrial laser cutting can be used in many different industries, such as aerospace, automotive, electronics and more. One of the great things about using an industrial laser cutter in these industries is the fact that it can work with many different materials. Whether it is metal, plastics, or wood, you’ll find an industrial laser cutter can accommodate your material with ease. It is this flexibility that has manufacturers in a wide range of industries turning to the laser cutter for their industrial needs

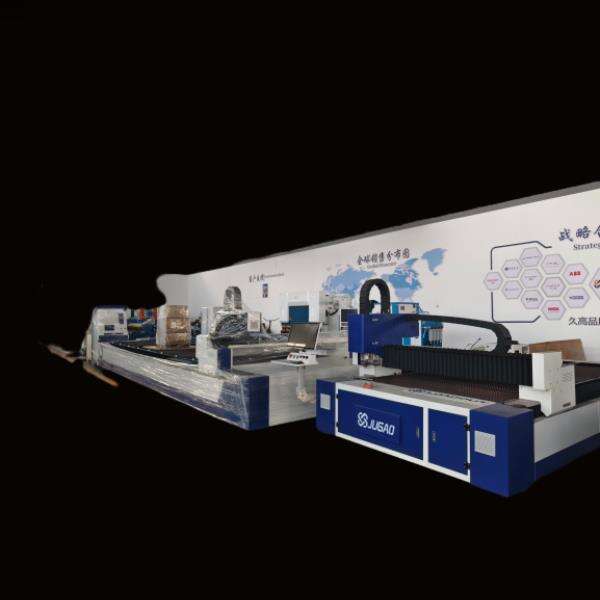

Learn More here Industrial laser cutters are changing the manufacturing industry and how we work by providing speed, precision, and so much more! These JUGAO laser cutting table are able to process materials at high speed and precision, which in turn enables manufacturers to create high quality items in a shorter period of time. This not only results in savings in term of costs, but also enables the companies to respond to customer requirements more rapidly. With the help of an industrial laser cutter, manufacturers can remain competitive and continue to lead the charge in their given industries.

The Technology Of Industrial Laser Cutters Activated by a computer, their release and focusing of its beam allows fact and precise cutting of all kinds of materials.

JUGAO laser cnc cutting machine function by using a highly powerful laser beam to cut everything. The beam is pointed at the material and is melted and vaporized, creating a clean, high-quality cut. The precision of the cut depends on the intensity of the laser beam, which is itself due to the power of the beam, and the speed of the beam itself. This enables very fine cuts that would not be possible through traditional cutting methods.

Manufacturers are able to increase efficiency in their production process with JUGAO fiber laser machine. These instruments can rapidly trim materials with precision that’s hard to believe, making for increased production speeds and improved quality products. Furthermore, industrial laser cutters can be programmed to perform a multitude of cutting jobs, making it easier for businesses to manufacture a plethora of products. Flexibility and efficiency like this mean that industrial laser cutters are an asset to any company needing to streamline their production processes and compete in today's whirlwind of an economy.

recognize significance RD Industrial laser cutter. laser cutting machines, rolling machines pipe bending machines, products, provide entire range after-sales services includes Spanish after-sales service ensure customers enjoy hassle-free use. addition continue invest research development, help promote latest technology product development meet ever-changing needs customers, assist customers maintain position marketplace.

Quality Builds Industrial laser cutter: Dedicated sheet metal machinery meticulously supervise each machine's quality ensure it line industry standards. strive provide highest quality products clients. laser cutters press brakes, pipe bending, rolling, rolling machines.Rapid Market Response: leveraging efficient production supply chain management, swiftly meet market demands. With large inventory, delivery times reduced one week, allows rapid equipment acquisition market advantage.

Press Brakes known reliability precision Industrial laser cutter various metal sheet processing; Laser Cutting Machines perform high-speed, high-precision cutting satisfy most complex requirements pattern design; Rolling Machines specialized forming metal sheets ensure high-quality production; Pipe Bending Machines offers flexible pipe bending solutions. product range focused accuracy, efficiency, stability enhance production efficiency quality products.

precision efficiency, Industrial laser cutter cutting machines able deal range materials. Rolling machines thanks amazing forming capabilities high-efficiency production, meet requirements many clients. Pipe bending machines employed mass production thanks flexibility stability. products essence industrial technology, enable manufacturing sector respond different challenges ensuring accuracy, efficiency flexibility.