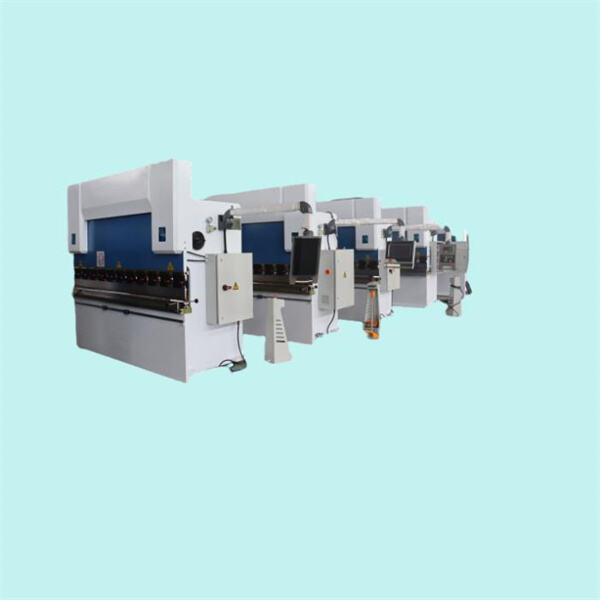

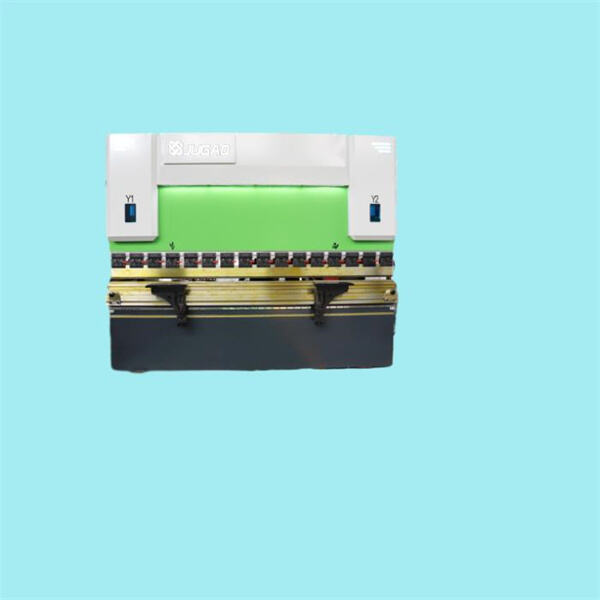

CNC Press machines are super cool devices for making stuff in a factory. They use specific technology to press metal and other substances into various forms. JUGAO is one brand that produces them. What Are CNC Press Machines and How Do They Work/Area of Application

CNC Press machines are programmed with a computer program that tells them how to press down on a material. That means you can tell the machine what to do, and it will do that thing the exact same way, every time. The machine’s special tools press metal sheets and related materials into various shapes and sizes. This ise technology ensures that the things we’re making are juuust right, no matter what.

There are a lot of advantages to using a CNC Press in 40t aluminum production line. One of the biggest pluses is that it saves time and money. Because the machine is computer-controlled, it is faster and more precise than a person can be. That way, the products could get made faster and with fewer mistakes. Plus, CNC Press machines can create more sophisticated shapes than standard manual press, meaning there’s no limit to what can be made.

CNC Press machines are very accurate, so they can do everything exactly the same way every time. This accuracy stems from the computer program that runs the machine. The program instructs the machine how much pressure to apply, how long to press and where to press. This might be a detail that in some way ensures that each product comes out perfect, without any accidents or variations.

The great thing about CNC Press machines is that they are so versatile. In other words, they’re suitable for all sorts of products. Whether they’re producing car parts, domestic appliances, or even toys, CNC Press equipment can handle anything. They can also be used for a variety of materials, including metal, plastic and wood. This versatility is what most makes CNC Press Brakes beneficial machines in numerous industries.

This is one of the reasons why so many production processes are made better by CNC Press machines. For one, they can operate more quickly than manual presses, allowing for more products to be made in a shorter period. Secondly, and most notably, CNC Press machines can work tirelessly with little or no mistakes. Meaning production can run smoothly without issues. And, last but not least, CNC Press machines can be configured so that they can also work unattended, when no one is at the facility. This helps companies save time and money by not needing to keep an eye on the production process 24/7.