CNC Press Brake TechnologyWe've been in awe of the cut-it-out-with-lasers-for-real process, a really cool machine that bends metal plates into various shapes. Picture a gigantic robot that can be directed to make precise bends in metal. CNC Press Brake Machines There is a lot to learn about how CNC press brake machines work and why they are amazing!

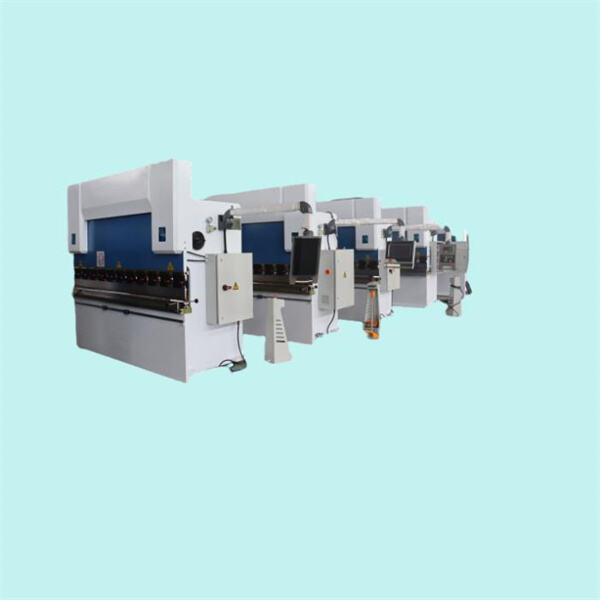

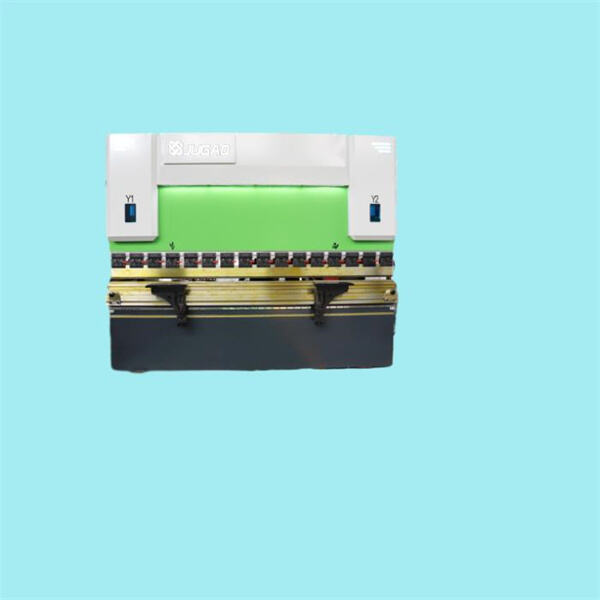

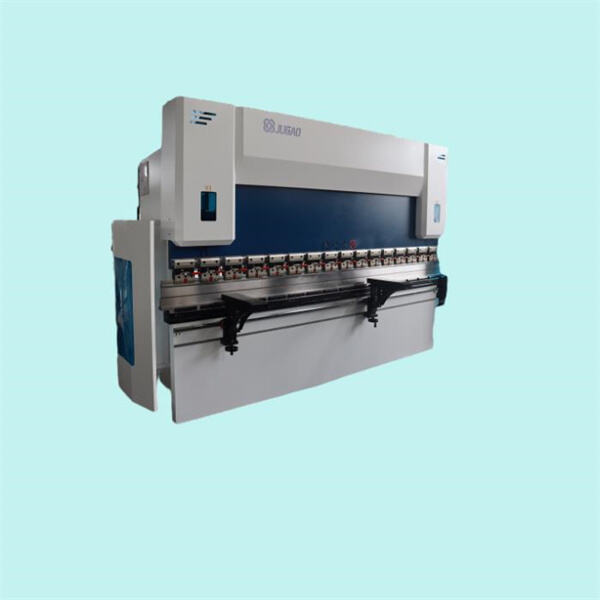

Factory and workshop metal plate CNC press brake machines bending machine The serial press brake machine is widely used in stainless steel, mild steel, brass, copper, aluminum, alloy and other sheet metal bending. They program computers to determine how metal should be bent, to ensure that every bend is the right bend. This technology allows for the easy fabrication of complex shapes and is very useful for making things.

The accuracy in the CNC Press Brake is one of the greatest things about them. The machine can bend metal to the nearest millimeter, so there is never a piece that’s not made just right. This in turn saves time and money, because workers don’t have to go back and correct mistakes as frequently. Moreover, CNC Press Brakes are capable of bending a variety of materials, whether you are dealing with thin sheets or thick plates.

CNC Press Brake machine employs hydraulic or electricity to push the metal plates into the shape you want. The computer program directs how much the metal should bend, so the finished product is exactly what’s called for. This accuracy is highly crucial for the aerospace, the cars and the constructions sectors, it is important to be precise.

CNC Press Brake machines make factories work faster and more effective. These machines can bend metal plates faster and more precisely than by hand, enabling more pieces to be produced more rapidly. This can help companies stay on time and in big orders seamlessly. Also, CNC Press Brakes don’t require to take breaks and can be programmed to run for long periods of time, adding further productivity.

And just as technology will get better, so will CNC Press Brake machines. The future of these cameras might bring artificial intelligence that makes them both more accurate and faster — and robots that can do it all automatically. These advances will continue to make CNC Press Brakes crucial for metal forming in the years to come.