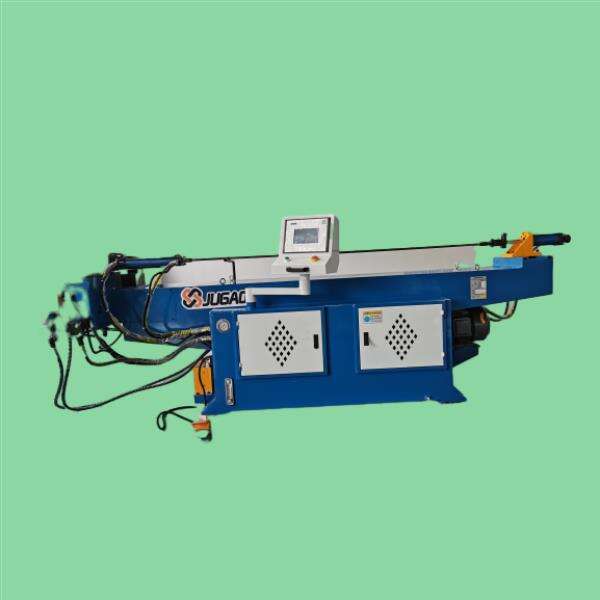

Tubing metal bending has become a lot more creative because of the incredible CNC bender. This powerful model allows you to accurately and efficiently bend metal tube, an essential tool for many businesses. Today we are going to get to know what a CNC bender is capable of in metalworking and how you can make your workshop work better with all the tips to use it well.

Zu the CNC bender The CNC bender is very precise bung and t. This machine is programmed by a computer to bend metal tubes with fantastic precision. No more manual bending or estimating—no matter what, the CNC bender is there to make sure your tube gets bent exactly how it is supposed to be bent. Such precision is important in industries where the smallest screwup can create major problems.

One of the best ideas in metalworking is of using a CNC bender. With this machine you are able to make intricate shapes and designs that would be difficult to produce with old methods. No matter if you are manufacture furniture, car components, ornaments, or you are a small business owner, the CNC bender can make your design hope come true soon.

To increase the productivity of your workshop with a CNC bender is a HUGE deal! You can easliy save time and labour by this machine.. That means you can handle more work and meet tight deadlines without sacrificing the quality of your work. You can produce more items while maintaining a nice finish with a CNC bender.

Here are some tips and tricks from the pros to maximize your CNC bender. First, do what you can so that your machine does its job well. Clean, oil the moving parts and inspect it some more. Second, improve your bending programs to waste less material and be more efficient with your time. With the ability to tweak your settings, you’ll be drawing and typing faster while more accurate. Third, train your operators well so that they operate the machine properly. Good training can reduce the potential for errors and increase productivity.