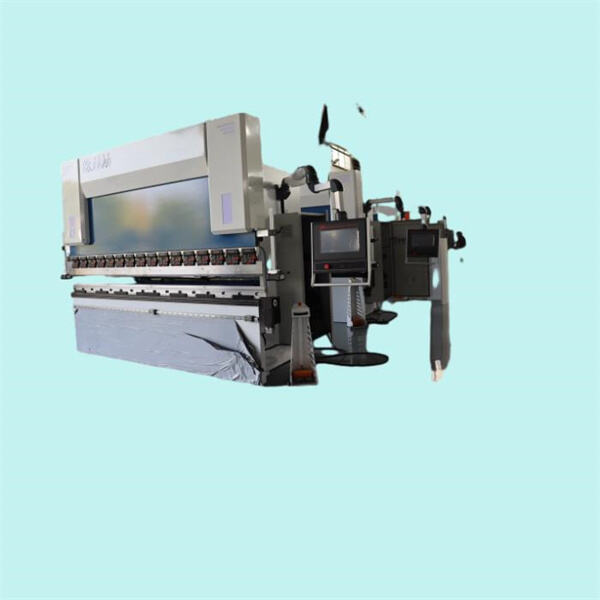

Automatic press brakes are bad ass machines that help to bend metal quickly and with precision. These machines use robots to do the bending, which means it all happens faster and more precisely. So how can these amazing machines help businesses produce great products?

One of the most impressive things about using automatic press brakes (like the ones produced by JUGAO) is that they enable companies to work quickly. On a typical press brake, workers must prepare the machine and adjust it for every single bend. This can be time-consuming, and can sometimes result in errors. And in the fiber laser welder, robots can do this work in short order, and that will make everything nice and simple.

Automated press brake equipment is very accurate so it can produce true bends in metal items. The robots are programmed to bend the metal at precisely the right angle and in just the right place each time. Such precision is critical to making sure products are good quality and up to standard.

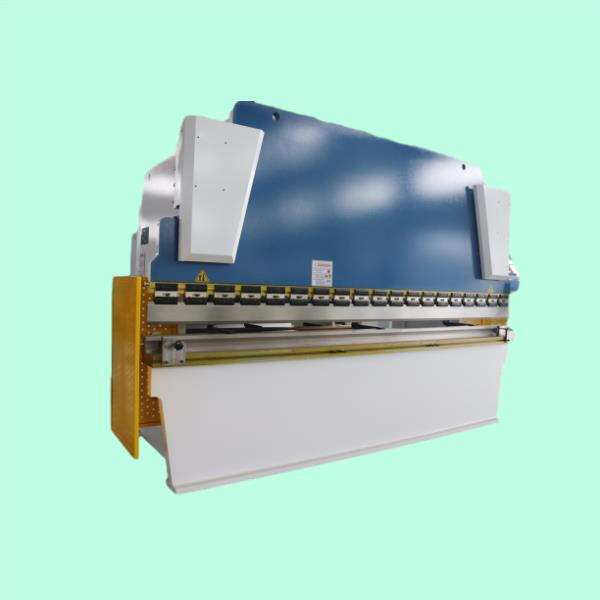

Companies can run their production easily with the help of automated press brake systems. Because the robots are fast and precise, companies can produce more goods in less time. This allows them to satisfy customer needs and also raise their profits. And when everything operates smoothly, employees can concentrate on other important work.

Automatic press brake controls also allow you more accuracy and repeatability One major advantage to having automatic press brake controls is that they give you that extra accuracy and repeatability. People can make mistakes on regular press brakes, and mistakes on a press brake can be a problem. But with automated controls that guide the process, companies can ensure that every bend is the same every time. This makes the products better than they would have been and saves both time and cost by minimizing the need to correct errors.