If you are in a special project, you are probably in need of bending a sheet metal, then you may be needed the 12’ sheet metal brake. A sheet metal brake is a machine that allows you to make precise bends in sheet metal easily. So today we have a new guide for you, and we are going to learn how to use a 12 ft sheet metal brake, covering its essentials and also some helpful tips that you can use to get better at it.

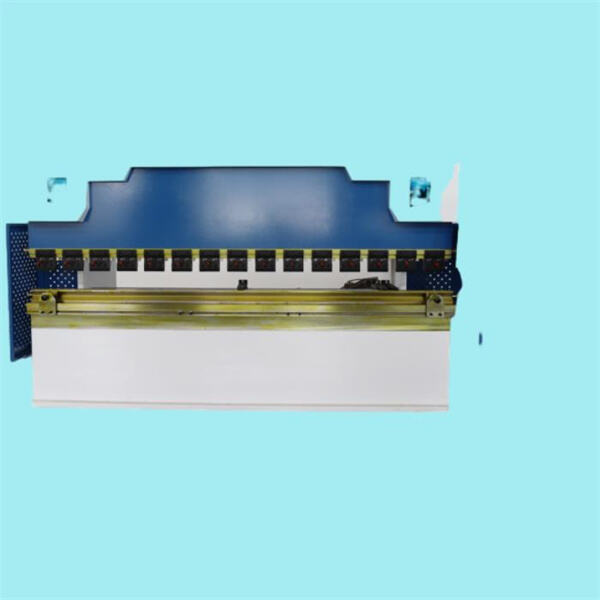

How does a 12 ft sheet metal brake work works Before you utilize a 12 ft sheet metal brake, you should know how it works. A sheet metal brake has a flat surface onto which you place your sheet metal. It also has a clamping bar to keep the metal in place while you bend it. Using the brake: to use the brake the sheet metal is placed on the flat surface and the clamping bar is set to the angle you want the sheet to be bent to then simply pull the handle down and the metal will bend.

When attempting to make precise bends on a 12 foot sheet metal brake, ensure that your sheet metal lines up with your desired bend line before bending. Use a square or ruler to verify that the edge of the metal is level with the edge of the brake. And be sure to use the appropriate pressure when bending. You press too gently, the bend is fragile. With too heavy a hand, metal can be made to crack.

Operating a 12 ft sheet metal brake If you want to use a 12ft metal sheet efficiently with a metal brake, there are a few things to plan for before you start forming your bends. As you consider the sequence of bends you have to make, set the clamping bar to the appropriate angle for each one. It’s important to take your time bending – rushing can result in mistakes that are difficult to correct.

A pair of 12 ft sheet metal brakes are useful in a large number of applications, such as fabricating custom pieces to go on a roof or fabricating ductwork for heating and cooling systems. This is a great tool for someone who either works with metal sheeting for a living or likes to take on their own do-it-yourself projects.

When choosing a material to use for your project, consider how thick the sheet metal is that you’ll be bending. Thinner metals are easier to bend, and thicker ones are harder. Also consider the metal’s finish. Some metals, such as stainless steel, may require special tools to bend properly.