การวิเคราะห์ประสิทธิภาพของการตัดและแกะสลักด้วยเลเซอร์

เทคโนโลยีการตัดและสลักด้วยเลเซอร์มีการนำไปใช้อย่างแพร่หลายในอุตสาหกรรมการผลิต การสร้างสรรค์งานศิลปะ และอิเล็กทรอนิกส์ เนื่องจากมีความแม่นยำสูง มีประสิทธิภาพ และมีความสามารถในการประมวลผลแบบไม่สัมผัส รายงานฉบับนี้นำเสนอการวิเคราะห์อย่างละเอียดเกี่ยวกับหลักการ สมรรถนะที่สำคัญ ปัจจัยที่มีอิทธิพล การประยุกต์ใช้งาน และแนวโน้มในอนาคตของการตัดและสลักด้วยเลเซอร์

หลักการพื้นฐาน

1. การตัดด้วยเลเซอร์

การตัดด้วยเลเซอร์ใช้ลำแสงเลเซอร์ที่มีความหนาแน่นพลังงานสูงเพื่อทำให้วัสดุละลาย เผาให้ระเหิด หรือจุดระเบิด ในขณะที่ก๊าซช่วยเหลือ (เช่น ออกซิเจน ไนโตรเจน) จะพัดพาเศษวัสดุที่ละลายออกไป ทำให้สามารถแยกวัสดุได้อย่างแม่นยำ

2. การสลักด้วยเลเซอร์

การแกะสลักด้วยเลเซอร์เกี่ยวข้องกับการกัดเซาะแบบเฉพาะที่หรือปฏิกิริยาทางเคมีบนพื้นผิวของวัสดุ เพื่อสร้างเครื่องหมายหรือลวดลายที่คงทน ต่างจากการตัด การแกะสลักโดยทั่วไปจะไม่เจาะทะลุวัสดุ แต่จะเปลี่ยนแปลงพื้นผิวของวัสดุ เช่น พื้นผิวสัมผัส หรือสี

เมทริกการทํางาน

1. ความแม่นยำ

ความแม่นยำในการจัดตำแหน่ง: โดยทั่วไป ±0.01 มม. โดยระบบระดับสูงสามารถทำได้ถึง ±0.005 มม.

ความซ้ำได้: โดยทั่วไปอยู่ในช่วง ±0.02 มม. สำหรับการประมวลผลแบบชุดที่สม่ำเสมอ

ความกว้างเส้นต่ำสุด: ขึ้นอยู่กับขนาดจุดโฟกัสของเลเซอร์ (10–100 ไมครอน); เลเซอร์ความเร็วสูงสามารถทำให้เกิดการแกะสลักในระดับไมครอน

2. ความเร็วในการประมวลผล

ความเร็วในการตัด: ขึ้นอยู่กับความหนาของวัสดุและกำลังเลเซอร์ (เช่น เลเซอร์ CO₂ สามารถตัดเหล็กกล้าไร้สนิมหนา 1 มม. ได้ที่ความเร็ว 20 ม./นาที)

ความเร็วในการแกะสลัก: การแกะสลักแบบเวกเตอร์สามารถทำได้ถึง 1000 มม./วินาที ในขณะที่การแกะสลักแบบแรสเตอร์จะช้ากว่าเนื่องจากวิธีการสแกน

3. ความเข้ากันได้ของวัสดุ

| วัสดุ | LaserType | ประสิทธิภาพ |

| โลหะ (เหล็กกล้าไร้สนิม, อลูมิเนียม, ทองแดง) | เลเซอร์ไฟเบอร์, เลเซอร์ CO₂ กำลังสูง | การตัดความแม่นยำสูง การแกะสลักด้วยการช่วยของออกซิเดชัน |

| วัสดุที่ไม่ใช่โลหะ (ไม้ อคริลิก หนัง) | เลเซอร์ CO₂ (10.6 µm) | การตัดเรียบ แกะสลักได้ละเอียด |

| วัสดุคอมโพสิต (PCB เส้นใยคาร์บอน) | เลเซอร์ UV (355 nm) | เขตที่ได้รับผลกระทบจากความร้อนน้อยที่สุด (HAZ) การแกะสลักที่มีความละเอียดสูง |

4. คุณภาพพื้นผิว

ความหยาบของรอยตัด: โดยทั่วไป Ra < 10 µm (เลเซอร์ไฟเบอร์สามารถทำได้ Ra < 5 µm สำหรับโลหะ)

การควบคุมความลึกของการแกะสลัก: ปรับได้ผ่านกำลังและจำนวนรอบ (ความแม่นยำ ±0.01 มม.)

ปัจจัยสำคัญที่มีผลต่อประสิทธิภาพ

1. พารามิเตอร์เลเซอร์

ความยาวคลื่น: UV (355 นาโนเมตร) สำหรับสลักละเอียด; CO₂ (10.6 ไมครอน) สำหรับวัสดุที่ไม่ใช่โลหะ

กำลังไฟฟ้า: กำลังสูงเพิ่มความเร็ว แต่อาจทำให้เกิดการบิดงอจากความร้อน

ความถี่ของพัลส์ (เลเซอร์แบบพัลส์): ส่งผลต่อประสิทธิภาพและความร้อนที่เกิดขึ้น

2. ระบบออปติก

เลนส์โฟกัส: ความยาวโฟกัสกำหนดขนาดจุดและระยะชัดลึก (เลนส์โฟกัสสั้นเพิ่มความแม่นยำ)

คุณภาพลำแสง (M²): ลำแสงใกล้ค่าดิฟแฟรกชัน (M² ≈ 1) ให้รอยตัดที่เรียบเนียน

3.การปรับปรุงกระบวนการ

ก๊าซช่วยตัด: ออกซิเจนเพิ่มความเร็ว (แต่ทำให้ขอบเกิดออกซิเดชัน); ไนโตรเจนให้รอยตัดที่สะอาด

กลยุทธ์การสแกน: แรสเตอร์สำหรับการแกะสลักพื้นที่ขนาดใหญ่ เวกเตอร์สำหรับเส้นขอบ

Applications

1. การผลิตอุตสาหกรรม

การผลิตแผ่นโลหะ: ตัดชิ้นส่วนยานยนต์/อากาศยาน

อิเล็กทรอนิกส์: การตัด FPC (Flexible PCB), การเจาะไมโคร PCB

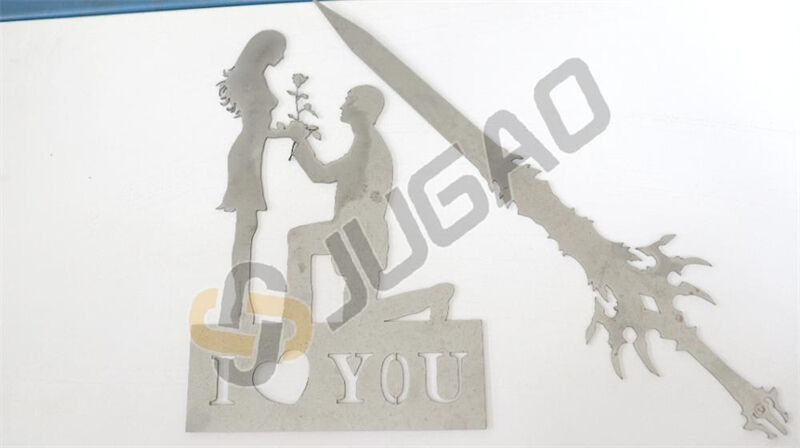

2. งานสร้างสรรค์และการออกแบบเฉพาะ

งานศิลปะ: การสลักบนไม้/อะคริลิก, การสลักบนหนัง

ภาพนูน 3 มิติ: การสลักแบบเกรย์สเกลเพื่อให้ได้เอฟเฟกต์ความลึก

3. งานการแพทย์และวิจัย

เครื่องมือผ่าตัด: เครื่องมือสเตนเลสสตีลที่ถูกตัดด้วยความแม่นยำ

ไมโครโปรเซสซิ่ง: เลเซอร์แบบอัลตราฟาสต์ (เฟมโตวินาที/พิโกวินาที) เพื่อสร้างไมโครสตรัคเจอร์

แนวโน้มในอนาคต

1. พลังงานและประสิทธิภาพสูงขึ้น: การประมวลผลด้วยหลายลำแสงเพื่อเพิ่มอัตราการผลิต

2. การทำงานอัตโนมัติอัจฉริยะ: การปรับแต่งพารามิเตอร์โดยใช้ AI

3. เลเซอร์สีเขียว: เลเซอร์ไฟเบอร์ที่ประหยัดพลังงาน

4. การนำเลเซอร์ความเร็วสูงมากมาใช้: การขยายตัวในด้านการแพทย์และเซมิคอนดักเตอร์

สรุป

การตัดและแกะเลเซอร์ให้ความแม่นยำและความหลากหลายที่เหนือชั้น ทำให้เป็นสิ่งที่ขาดไม่ได้ในการผลิตยุคใหม่ ความก้าวหน้าในแหล่งกำเนิดเลเซอร์ ระบบอัตโนมัติ และการควบคุมกระบวนการทำงาน จะช่วยเพิ่มประสิทธิภาพและการประยุกต์ใช้งานของเลเซอร์ให้มากยิ่งขึ้น