Hur man förbättrar DELEM DA-58T-prestanda med effektiva systemunderhållstips

Innehållsförteckning

• Introduktion

• Kärnunderhållsfunktioner

• Maximal utnyttjande av maskintimmar och slagräknare

• Modulbyte och lagring av diagnostikdata

• Åtkomst till och tolkning av systeminformation

• Förståelse av modul-ID:n och OEM-specifika filversioner

• Vanliga frågor (FAQ)

◦ Vilka systemunderhållsåtgärder bidrar till förbättrad prestanda hos DELEM DA-58T?

◦ Hur ofta bör tryckbromsunderhåll utföras?

◦ Vad är den optimala metoden för att kalibrera en tryckbroms för precision?

• Slutsats

Om du vill förbättra prestandan för din DELEM DA-58T-maskin är det grundläggande att förstå praktiska systemunderhållsmetoder. I denna guide delar jag nyckeltips för systemunderhåll som kan märkbart förbättra din utrustnings effektivitet och livslängd. Oavsett om ditt mål är att maximera maskintid eller effektivisera dagliga operationer kommer de råd som ges här att ge dig kunskapen att hålla DELEM DA-58T igång smidigt. Genom att tillämpa dessa underhållsstrategier kan du säkerställa att maskinen fungerar på topp, minska driftstopp och öka den totala produktiviteten.

Introduktion

Att integrera systemunderhåll i DELEM DA-58T:s arbetsflöde börjar med att lära sig använda maskinläget, vilket är tillgängligt via navigeringsknappen.

Genom att trycka på denna knapp växlar kontrollpanelen till maskinläge, vilket ger operatörer tillgång till kritiska konfigurationsinställningar och maskinkarakteristik – båda två viktiga för att optimera prestanda och schemalägga underhåll effektivt.

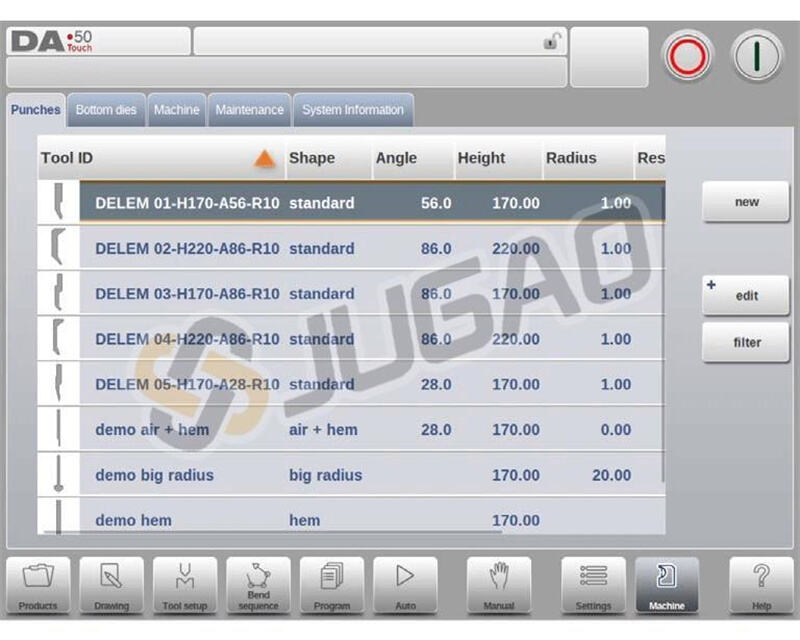

Inom maskinläget är inställningarna organiserade i flera flikar, där varje flik grupperar relaterade ämnen om maskinens drift. Denna strukturerade layout gör inte bara navigering enklare utan förenklar också underhållet: användare kan snabbt hitta specifika inställningar som kan påverka maskinens prestanda och tillförlitlighet.

Reguljär systemunderhåll är viktigt för DELEM DA-58T för att upprätthålla optimal prestanda och lång livslängd. Med Machine-läge kan operatörer enkelt justera inställningar som påverkar maskinens beteende och beräkningsnoggrannhet. Funktionen för horisontell dra-and-släpp gör det möjligt för användare att komma åt alla konfigurationsflikar, vilket säkerställer en komplett översikt över maskinens inställningar. Detta strukturerade tillvägagångssätt vid underhåll hjälper till att minimera driftstopp och hålla effektiviteten hög.

Dessutom har underhållspanelen och systeminformationspanelen en central roll för att övervaka maskinens hälsa och distribuera systemuppdateringar. Regelbundna uppdateringar åtgärdar programvaruproblem och lägger till nödvändiga förbättringar, medan panelerna ger insikter i prestandatrender och potentiella problem. Genom att vara proaktiv med underhåll och uppdateringar kan operatörer säkerställa att DELEM DA-58T förblir tillförlitlig och funktionsduglig på lång sikt.

Kärnfunktioner för underhåll

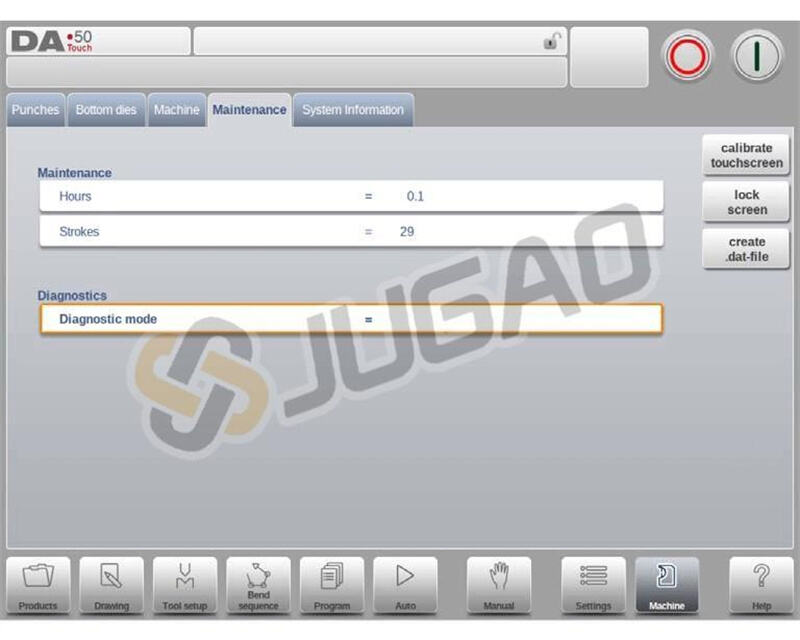

Systemunderhållsfliken innehåller viktiga verktyg och data, inklusive räknare för maskintimmar, slagräknare, verktyg för modulbyte samt funktioner för lagring av diagnostikdata.

Nyckelfunktioner – översikt:

• Timmar: Visar den totala antalet timmar som maskinen har varit i drift.

• Slag: Anger hur många slag pressbommen har utfört.

• Diagnostikläge: Detta läge kan aktiveras eller inaktiveras för underhållsändamål med hjälp av en unik åtkomstkod. För information och åtkomstkoder, kontakta tillverkaren direkt.

• Kalibrera pekskärm: Justera skärmens kalibrering enligt operatörens preferenser.

• Lås skärm: Tillfälligt låser skärmen så att du kan rengöra den utan att oavsiktligt ändra inställningar. Skärmen låses upp automatiskt efter 10 sekunder.

• Skapa .dat-fil: När diagnostikläge är aktivt sparar denna funktion kritiska produkt- och styrdata till en ansluten USB-enhet – detta underlättar underhållsunderstöd.

Maximera maskintimmar och slagräknare

DELEM DA-58T levereras med inbyggda maskintimmar- och slagräknare som spårar hur maskinen används. Dessa räknare ger viktig information om användningsnivåer, vilket gör att operatörer kan schemalägga underhåll vid rätt tillfälle. Genom att följa dessa mått blir det enklare att planera förebyggande underhåll och säkerställa att maskinen förblir i gott skick.

Modulbyte och lagring av diagnostikdata

Modulbyte är en viktig underhållsåtgärd som måste följa tillverkarens rekommenderade procedurer. Det är också viktigt att lagra diagnostikdata korrekt – detta underlättar snabb felsökning när problem uppstår. Effektiv lagring av diagnostikinformation snabbar upp problemlösningen och minskar driftstopp. Båda dessa steg är avgörande för att förlänga livslängden på DELEM DA-58T och bibehålla dess tillförlitlighet.

Få tillgång till och tolka systeminformation

Fliken Systeminformation på DELEM DA-58T är en ovärderlig resurs för operatörer, eftersom den ger viktiga detaljer som stödjer underhåll och prestandaoptimering. Nedan följer en översikt över dess huvudsakliga funktioner:

• Information om programvaruversion: Den här fliken visar den programvaruversion som för närvarande är installerad på maskinen. Att hålla programvaran uppdaterad är avgörande för att undvika prestandaproblem och säkerställa att maskinen använder de senaste funktionerna och förbättringarna.

• Installerade moduler och deras ID:n: Operatörer kan se ID:n för de installerade modulerna – detta är viktigt för att identifiera komponenter och säkerställa att eventuella uppdateringar eller integrationer är kompatibla.

• Versioner av OEM-specifika filer: Att känna till vilka OEM-specifika filer som är installerade hjälper till att bibehålla kompatibilitet och funktionalitet mellan alla systemkomponenter.

• Uppdateringsfunktioner: Fliken innehåller även verktyg för att uppdatera programvara, vilket gör det enkelt att hålla systemet aktuellt och minimera driftstopp.

För att hålla systemet igång effektivt bör operatörer regelbundet kontrollera denna flik. Genom att proaktivt komma åt och förstå den här informationen kan de åtgärda potentiella problem innan de påverkar maskinens prestanda.

Även om de tekniska detaljerna vid första anblick kan verka komplexa förenklar det långsiktigt underhållet. Regelbundna programvaruuppdateringar och korsreferenser med de senaste versionerna säkerställer att DELEM DA-58T håller jämna steg med både program- och hårdvaruframsteg. Detta proaktiva tillvägagångssätt minskar oväntade driftstopp avsevärt och förbättrar maskinens totala funktion.

Förståelse av modul-ID:n och OEM-specifika filversioner

DELEM DA-58T använder modul-ID:n och OEM-specifika filversioner för att identifiera och hantera olika systemkomponenter. Att känna till dessa ID:n och versioner underlättar effektiv felsökning och säkerställer att rätt uppdateringar och moduler används. Att förstå dessa aspekter bidrar till att öka utrustningens prestanda och tillförlitlighet.

Nyckelkomponenter:

• Programversion: Visar den aktuella versionen av maskinens programsystem.

• Alternativ-ID: Visar det unika ID:t för kontrollsystemets valfria funktioner.

• Sekvens- och delem.def-versioner: Anger versionsnummer för den aktiva sekvensen och konfigurationsfilen delem.def.

Funktionen Uppdatera programvara låter dig uppdatera programvaran med hjälp av en USB-enhet – detta inkluderar en katalogbrowser som hjälper till att välja och installera rätt uppdatering.

Backup-systemfunktionen skapar en fullständig systembackup på en USB-enhet, vilket genererar en tidsstämplad fil som innehåller Delem-programvara, OEM-data och användarfiler.

Återställningssystemfunktionen å andra sidan låter dig återställa systemet från en tidigare backup, med möjlighet att välja specifika data att återställa.

Slutligen genererar Offline-programvarufunktionen en installationsfil för att uppdatera befintlig offline-programvara, så att den förblir kompatibel med maskinens kontrollprogramvara.

Dessa funktioner i avsnittet för systemunderhåll är avgörande för att upprätthålla DELEM DA-58Ts prestanda och kompatibilitet.

Frågor som ofta ställs (FAQ)

Vilka systemunderhållsåtgärder hjälper till att förbättra DELEM DA-58Ts prestanda?

Regelbundet systemunderhåll – inklusive programvaruuppdateringar och regelbundna besiktningar – är nödvändigt för optimal prestanda hos DELEM DA-58T. Se till att styrsystemet kör den senaste programvaruversionen och kontrollera alla rörliga delar på tecken på slitage eller skador.

Hur ofta bör underhåll av böjpress utföras?

Rutinmässigt underhåll bör utföras var 500:e drifttimme. Detta inkluderar att inspektera nyckelkomponenter, rengöra maskinen och smörja rörliga delar.

Vad är den optimala metoden för att kalibrera en böjpress för hög precision?

För att kalibrera en böjpress noggrant måste du först säkerställa att maskinen är ordentligt nivellerad. Använd sedan ett digitalt mätinstrument för att mäta vinkeln på böjdosen och justera den enligt tillverkarens anvisningar.

Slutsats

Sammanfattningsvis är konsekvent underhåll och systemuppdateringar nyckeln till DELEM DA-58T:s optimala effektivitet och lång livslängd. Genom att effektivt använda maskintimmar- och slagräknare, byta ut moduler korrekt och förstå systeminformation kan operatörer hålla sina maskiner i bästa skick. Vi uppmuntrar operatörer att följa ett regelbundet underhållsschema – detta kommer inte bara att förbättra maskinens prestanda utan också förlänga DELEM DA-58T:s livslängd.

För att få ut mesta möjliga av din maskin, överväg att kontakta vårt team för personlig support eller utforska ytterligare resurser. För mer information eller hjälp, tveka inte att kontakta oss eller gå igenom vår andra relaterade dokumentation.