Optimering av ESA S630 böjhantering: Nyckelstrategier och praktiska tips

Innehållsförteckning

• Att utnyttja senaste böjningsfunktionen

• Att dra nytta av maskinens funktionssida

• Praktiska metoder för att spara program

• Förbättra verktygsstrategier

• Navigera andra menysidor

• Använda fjärrprogramval

• Vanliga frågor (FAQ)

◦ Vad är de första stegen för att konfigurera ESA S630 Bend Management på en ny maskin?

◦ Kan ESA S630 Bend Management stödja anpassade böjningsprogram?

◦ Hur använder man fjärrval av program effektivt med ESA S630 Bend Management?

• Slutsats

För professionella som syftar till att förbättra sina arbetsflöden för böjningshantering erbjuder ESA S630-systemet oöverträffade optimeringslösningar. Du kanske undrar hur du kan tillämpa bästa praxis för att maximera effektiviteten och effektivisera operationerna – och den här guiden är utformad för att besvara det.

Denna artikel delar konkreta strategier för att låsa upp hela potentialen i ESA S630 Bend Management. Genom att anta dessa metoder omvandlar du dina böjningsoperationer: öka precisionen, minska driftstopp och slutligen öka produktionsvolymen. Låt oss utforska de steg som förvandlar vanlig böjningshantering till en effektiv, högpresterande process.

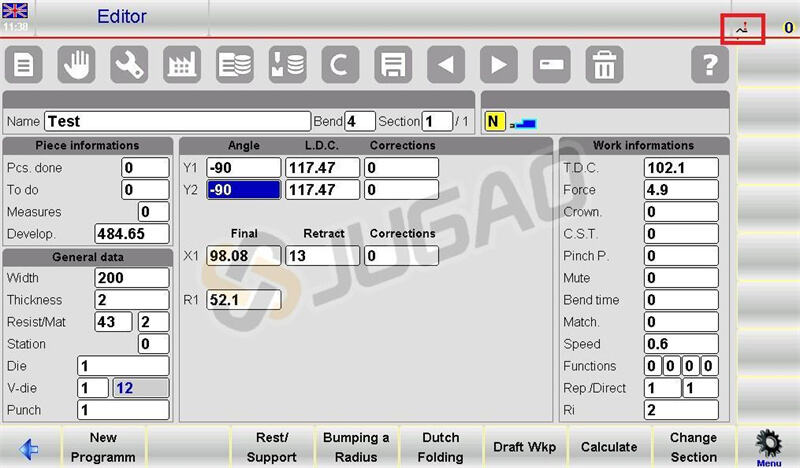

Utnyttja funktionen Senaste böjning

För att öka effektiviteten i bögningsoperationer är det avgörande att behärska funktionen "Sista böj" i ESA S630:s bögningsstyrningssystem. Denna funktion fungerar som en skyddsmekanism genom att markera den sista böjen i ett bearbetningsavsnitt, vilket förhindrar oavsiktlig infogning av ytterligare böjar. När den används korrekt hjälper den operatörer att upprätthålla exakta, felfria bearbetningssekvenser – du kan identifiera den via ikonen för sista böjen placerad i övre högra hörnet i figuren nedan:

Genom att integrera funktionen "Sista böj" i din arbetsflöde med ESA S630 kan noggrannheten förbättras avsevärt, särskilt vid hantering av komplexa bögningssekvenser med flera steg.

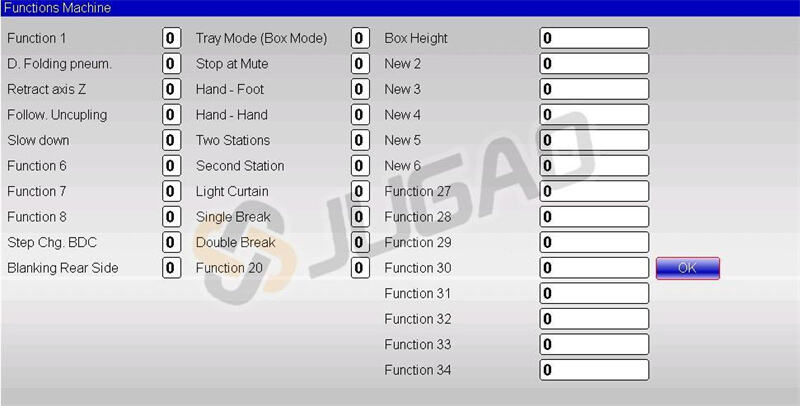

Maximera fördelarna med maskinfunktionsfönstret

I ESA S630:s bögningsstyrningsprogram är sidan "Maskinfunktioner" nyckeln till förbättrad maskinkontroll under bögning. Här kan operatörer ställa in anpassade funktioner för varje böj för att anpassa prestanda till specifika uppgifter.

För att komma åt den här funktionen: Tryck på motsvarande knapp på redigerarsidan och välj sedan alternativet 9>> Maskinfunktioner. Popup-fönstret erbjuder en rad inställningar för att finjustera operationer:

• D. Funktion för pneumatisk vikning: Aktiverar pneumatisk lyftning av verktyg, vilket säkerställer precision vid holländska vikbuktar.

• Z-axelns retraktionsfunktion: Justerar axlarna Z1 och Z2 baserat på "Z-avvikelsevärde" för att bibehålla bearbetningsprecision.

• Följaravkopplingsfunktion: Utför en frigörelsecykel för att styra rörelsen hos följarkomponenten.

• Saktas ner-funktion: Håller stöten i en låg hastighet under nedåtgången, vilket förbättrar kontrollen under buktcykeln.

• BDC-stegsförändringsfunktion: Möjliggör böjningsjusteringar vid det undre dödpunkten, vilket ökar noggrannheten.

• Bakre sidobalkens avstängningsfunktion: Fungerar tillsammans med MCS-säkerhetssystem för att inaktivera den bakre balken när det behövs.

• Fackläge (Boxläge) och Boxhöjdsfunktioner: Säkerställer säker böjning av boxformade arbetsstycken med hjälp av "laser safe"-system.

• Stanna vid tystningsfunktion: Möjliggör paus när hastighetsförändringar sker inom "laser safe"-systemet.

• Hand-fot och hand-hand-funktioner: Ger manuell stoppkontroll vid tystningspunkter för flexibel drift.

• Två stationer och andra stationens funktioner: Hanterar dubbel-pedaldrift när "laser safe"-systemet används.

Sidan "Maskinfunktioner" är avgörande för exakt kontroll i ESA S630 böjhantering – den låter dig anpassa operationer efter specifika arbetsstyksbehov, vilket säkerställer både effektivitet och säkerhet.

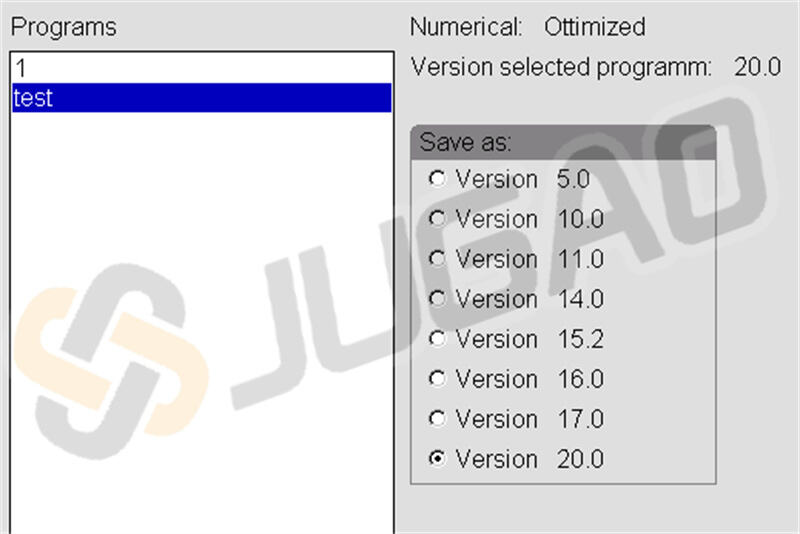

Praktiska metoder för att spara program

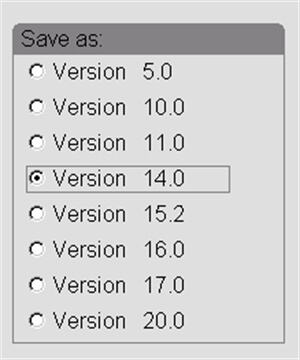

Effektiv programhantering är avgörande för smidig drift i ESA S630 böjhantering. Från och med version 10.1 har formaten för arbetsprogram utökats till att inkludera 20 funktioner. Även om version 10.x stödjer äldre programformat saknas stöd för bakåtkompatibilitet – därför måste du spara program i format som är kompatibla med tidigare versioner när det behövs.

Översikt över versionshantering

Versionssparningssidan förenklar programhantering genom att visa aktuella program, deras versionsindex, kryssrutor för att välja målversioner att spara samt funktionsknappar som [Spara som…] och [Spara ALLA som…].

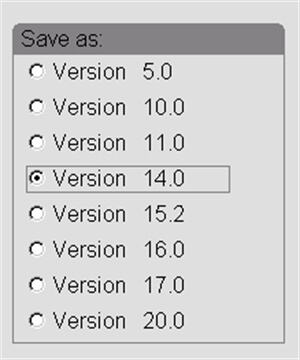

Spara ett enskilt numeriskt program

För att spara ett program i ett format som är kompatibelt med en äldre version:

1. Navigera till gränssnittet Programlista.

2. Klicka på [Spara version] för att öppna sparsidan.

3. Använd pekskärmen för att välja önskat format (till exempel Version 14.0).

4. Tryck på [Spara som…] för att namnge programmet och slutföra sparandet.

Spara alla program

För att spara alla befintliga program samtidigt:

1. Öppna Programlistan.

2. Gå till sparasidan genom att klicka på [Spara version].

3. Använd pekskärmen för att välja önskat format (till exempel Version 14.0).

4. Koppla in en formaterad USB-enhet i maskinen.

5. Välj [Spara allt som…] för att spara alla program på USB-enheten.

Dessa metoder ökar tillförlitligheten och effektiviteten i ESA S630 Bend Management, vilket säkerställer enkel åtkomst till program och kompatibilitet mellan olika systemversioner.

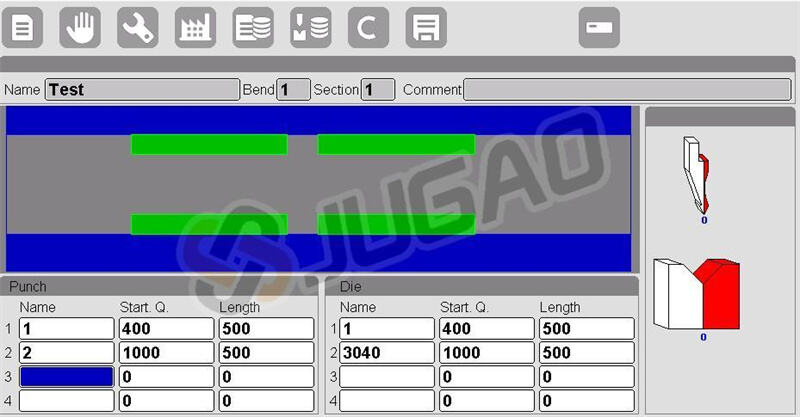

Förbättra verktygsstrategier

Effektiv ESA S630 Bend Management bygger på skicklig användning av sidan "Verktyg" – som hanterar arbetsstationer och automatiskt beräknar Z-axelpositioner. För att öppna denna sida: Gå till redigeraren och välj sedan alternativ 11 >> Verktyg. Gränssnittet visar en framsida av maskinen, där ikoner i form av "Tänder" representerar verktygen, och kontrollfönster finns på höger sida.

Längst ner på sidan visar två huvudfönster information för upp till fyra arbetsstationer, inklusive:

• Arbetsstationsnummer: Ange vilken arbetsstation som är aktiv (från 1 till 4).

• Verktygsidentifiering: Matcha namnen på die och punsch till de listade verktygen.

• Mått: Ange initiala mått – beräknade från punkt 0 om "Avstånd 0-inifrån axel" är aktiverat.

• Verktygslängder: Ange längden på verktyg för varje arbetsstation.

Genom att använda dessa funktioner kan du förbättra ESA S630 Bend Management: säkerställa exakt verktygsval, förenkla underhåll och öka den totala effektiviteten inom metallbearbetning.

Navigering av andra menysidor

Smidig drift av ESA S630 Bend Management kräver kunskap om hur man navigerar bland viktiga menyer. Här är hur du använder de viktigaste funktionerna:

Stänga av NC

För att säkert stänga ner CNC-systemet:

1. Tryck två gånger på den avsedda knappen för att öppna menyn.

2. Välj alternativet 5>> Stäng ner.

Visa programvaruversion

För att kontrollera programvaruinformation (inklusive SW-version):

1. Tryck två gånger på den avsedda knappen för att komma åt menyn.

2. Välj alternativ 6 >> Version.

Visa eller ändra logotypen

För att kontrollera eller ändra logotypvisning:

1. Tryck två gånger på den avsedda knappen för att öppna menyn.

2. Välj alternativ 7 >> Logotyp.

Genom att behärska dessa grundläggande menyfunktioner säkerställer du personlig och effektiv kontroll över ESA S630 Bend Management-systemet.

Använda fjärrprogramval

För att använda fjärrprogramval måste du först förbereda de nödvändiga resurserna och konfigurera CNC korrekt. För detaljerade steg om konfiguration, se maskintillverkarens handbok för maskinparametrar – detta säkerställer att läget fungerar som avsett.

Frågor som ofta ställs (FAQ)

Vad är de första stegen för att konfigurera ESA S630 Bend Management på en ny maskin?

Börja med att läsa maskinens användarhandbok för initiala installationsanvisningar. Konfigurera sedan CNC-parametrarna för att säkerställa kompatibilitet med ESA S630 Bend Management. Kontrollera slutligen alla anslutningar för att säkerställa smidig programintegrering och undvika driftproblem.

Kan ESA S630 Bend Management hantera anpassade böjningsprogram?

Ja, ESA S630 Bend Management är utformat för att hantera anpassade böjningsprogram. Du kan konfigurera CNC:n att acceptera dessa anpassade program och exekvera dem noggrant – denna flexibilitet hjälper till att möta unika produktionsbehov och förbättrar övergripande kapaciteter.

Hur använder man fjärrval av program effektivt med ESA S630 Bend Management?

För att effektivt använda fjärrprogramval, förbered först alla nödvändiga resurser (enligt tillverkarens riktlinjer). Konfigurera sedan CNC:n enligt anvisningarna i handboken för maskinparametrar. Korrekt konfiguration minimerar driftstopp och förbättrar driftseffektiviteten.

Slutsats

När du optimerar ESA S630 Bend Management kan en uppsättning kärnstrategier avsevärt öka driftseffektiviteten och minska driftstopp. Genom att prioritera exakt installation, utnyttja fjärrprogramval och genomföra regelbunden systemunderhåll kommer din vikbänksanläggning att leverera optimal prestanda. Dessa strategier samverkar för att effektivisera vikoperationer, förbättra precisionen och öka den totala produktiviteten.

För omfattande support och för att fullt ut kunna låsa upp potentialen i ESA S630 Bend Management, kontakta vårt expertteam. Vi står redo att erbjuda djupgående insikter, skräddarsydda lösningar och ytterligare dokumentation för att vägleda dig genom varje steg. Tveka inte att kontakta oss för konsultationer, extra resurser eller för att utforska relaterad dokumentation på vår webbplats. Genom att samarbeta med oss kan du säkerställa att din maskin fungerar med högsta effektivitet och konsekvent levererar exceptionella resultat.