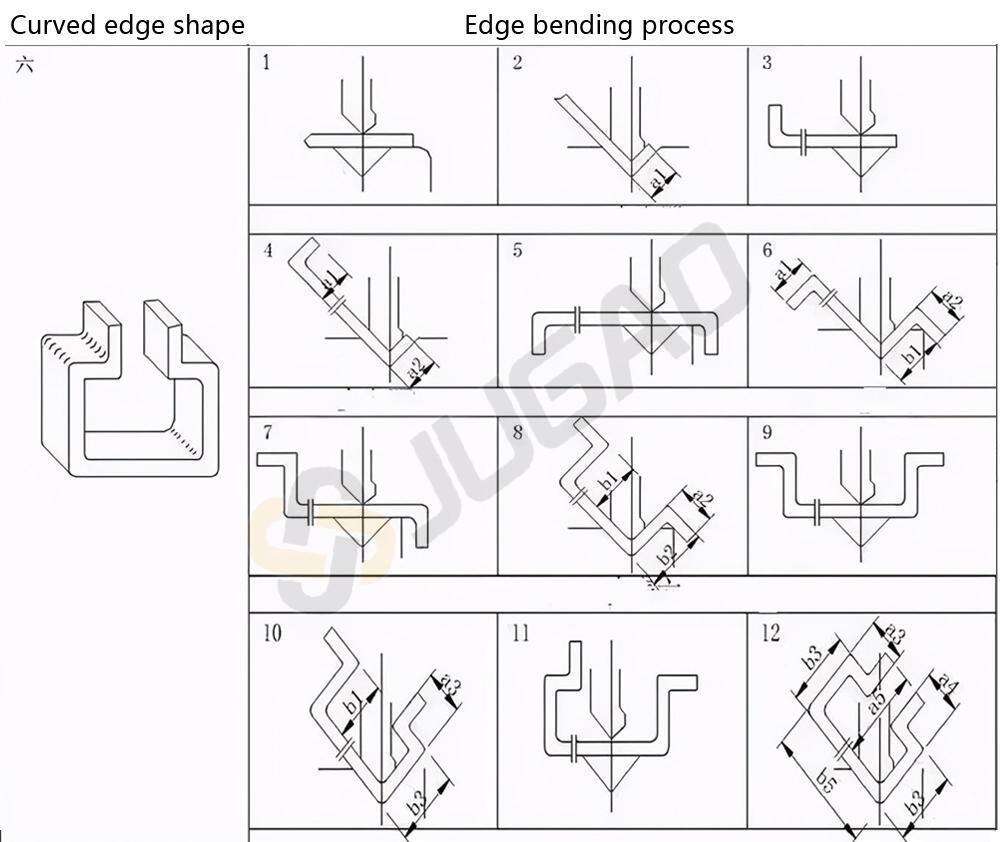

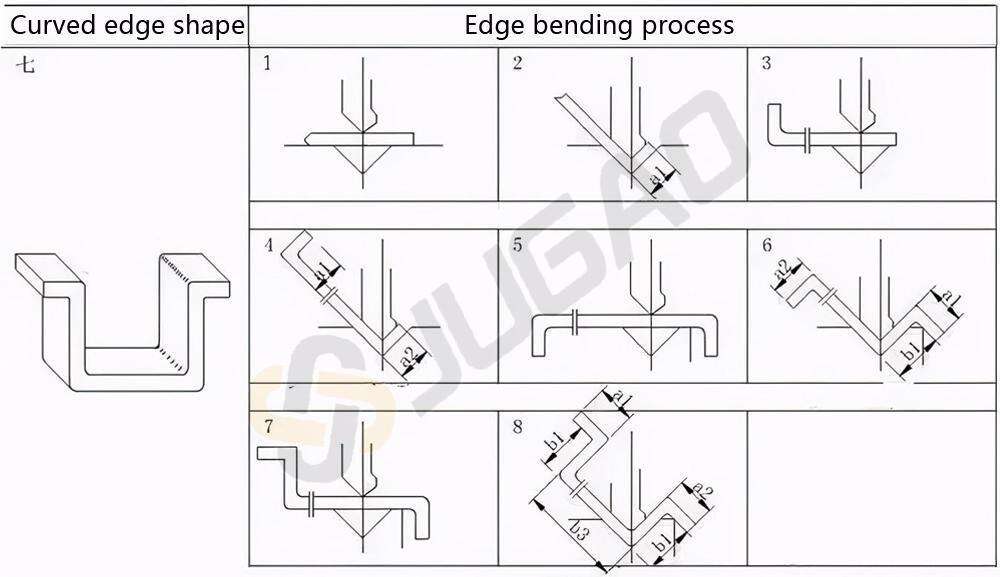

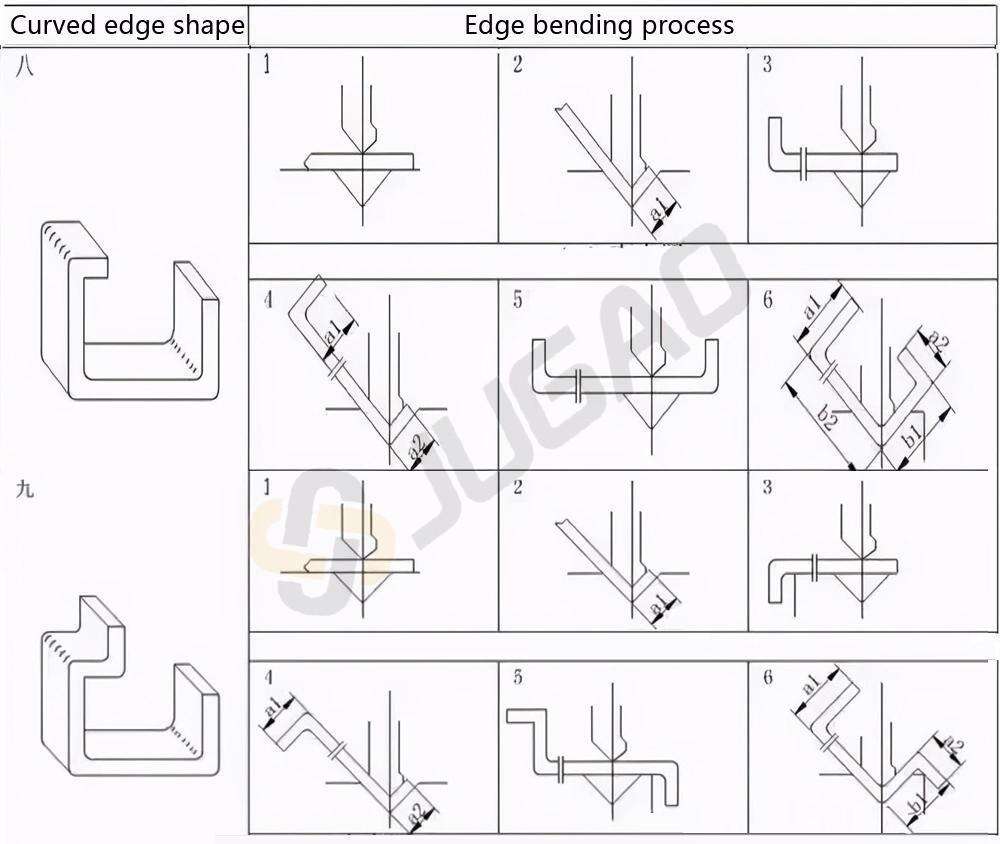

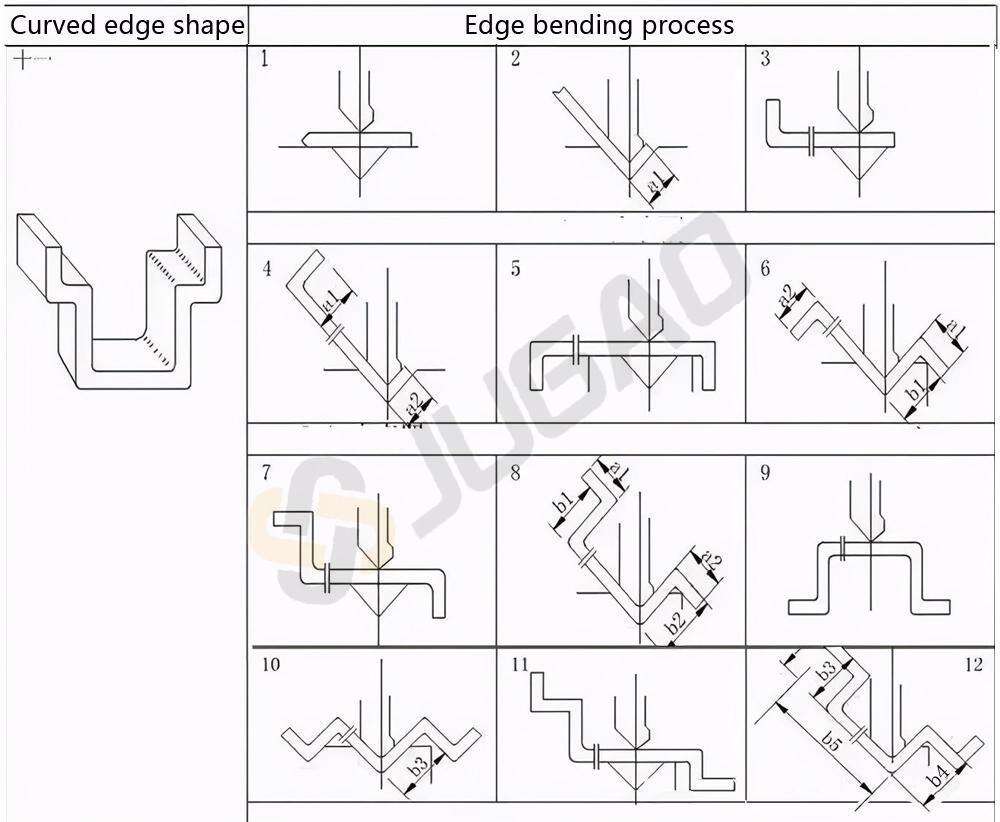

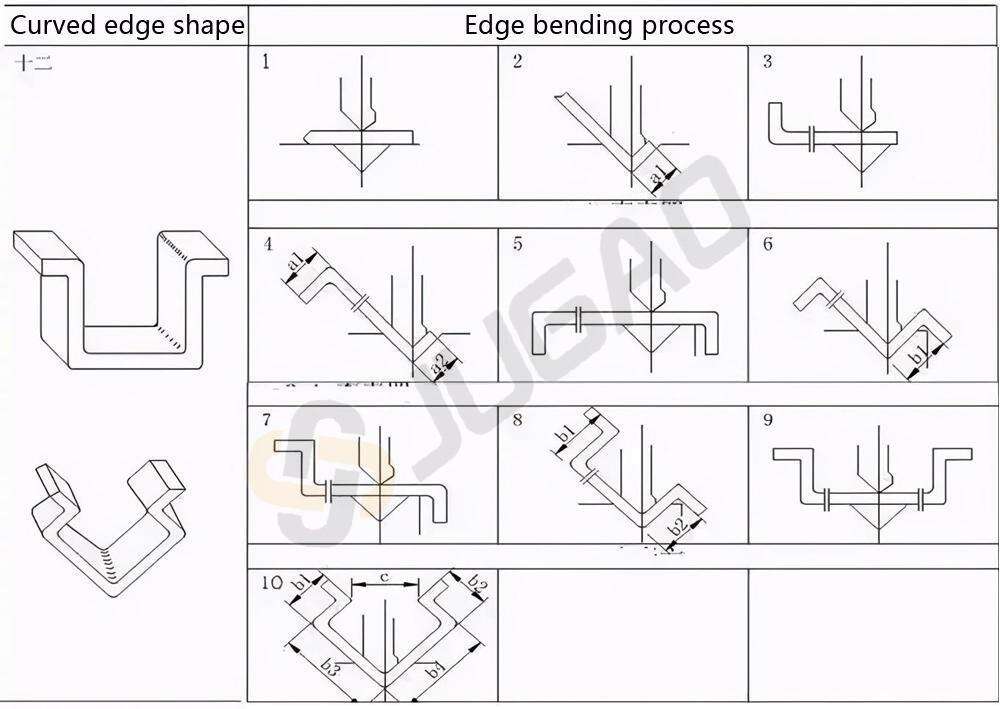

Sheet metal bending cutting sequence

The main considerations for sheet metal bending are: the principle that the previous bend should not affect the subsequent bend, and the principle that the bend should not push against the mold or machine tool.

The following is an explanation with reference to images:

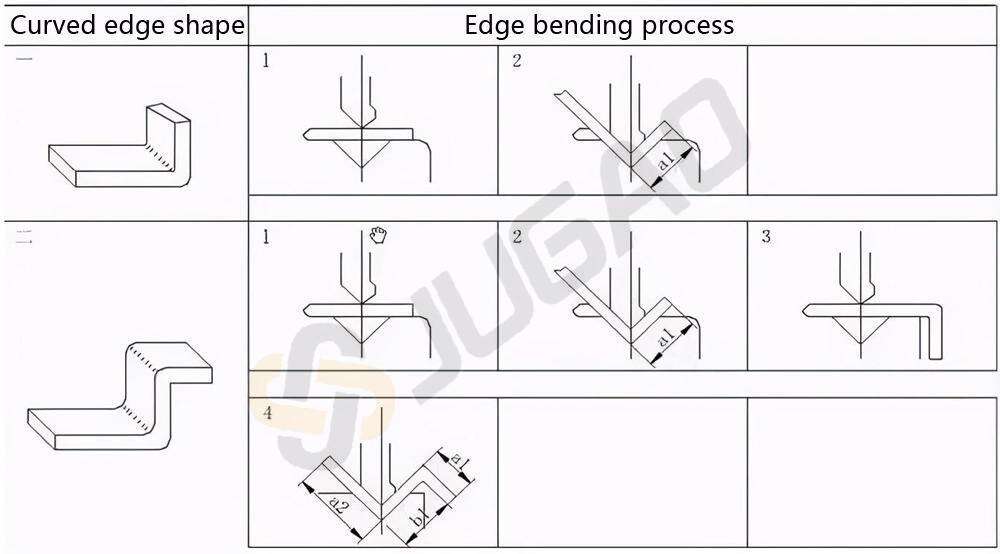

As shown in Figures 1 and 2: L-shaped bends mainly consider the minimum bending size; Z-shaped bends mainly consider the minimum bending size and the minimum height of the reverse bend.

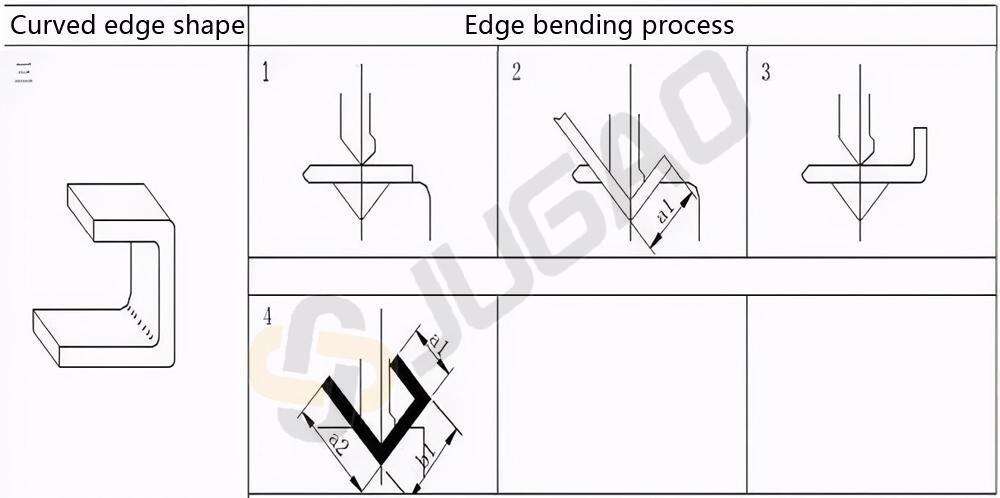

As shown in Figure 3: When bending channel steel, the main consideration is the ratio of dimension b1 to dimension a1. After bending, the first bend should not collide with the upper bending die.

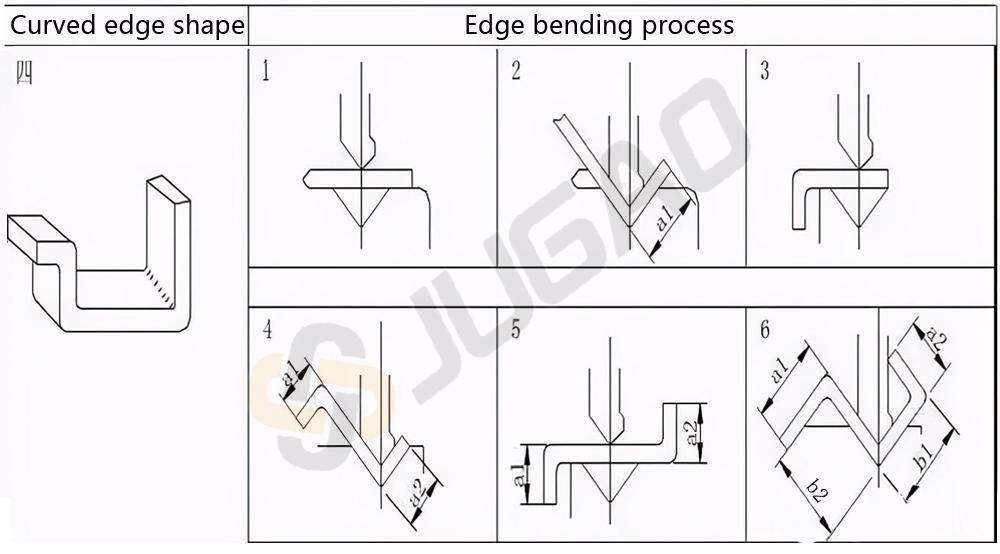

As shown in Figure 4: This bending requires consideration of various factors that appear in Figures 1, 2, and 3. Pay attention to the position of the hand holding the workpiece in step 5 to avoid pinching your hand.

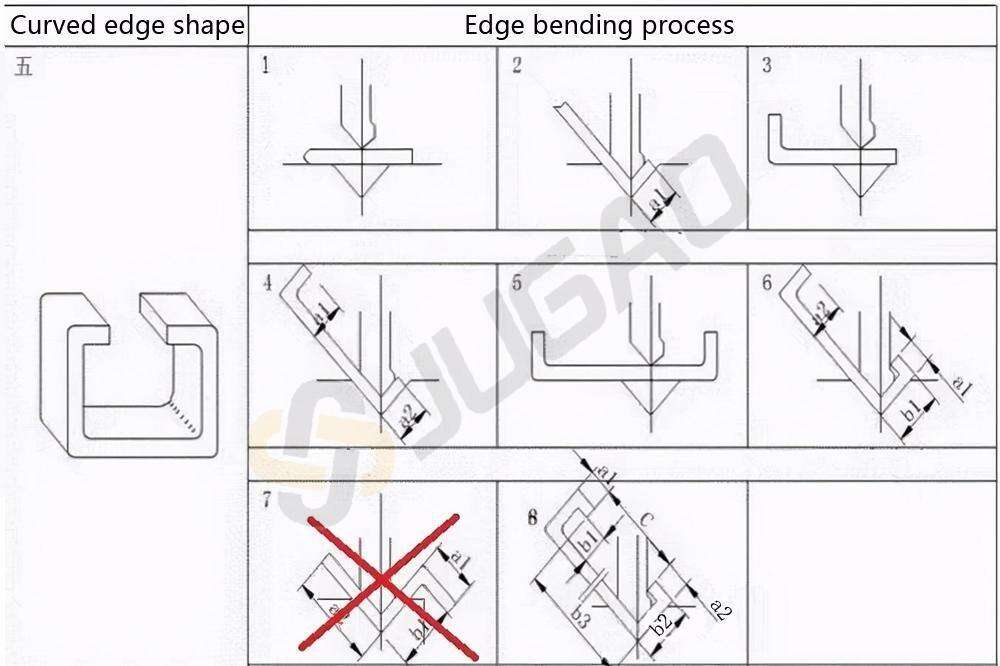

As shown in Figure 5: Step 7 is incorrect and unnecessary, and should be deleted.

As shown in Figure 6: Note that the length of the last step, b5, is relatively long. Any bend must not collide with the mold, let alone enter the mold. Exceptions apply to special molds.

As shown in Figure 7: This type of bend is a commonly used shape for reinforcing ribs, and the bending sequence must be learned.

Figures 8 and 9 show the bending sequence above; if you understand that, this shouldn't be difficult.

Figure 10 has been deleted because the bending shapes are repeated and the main image doesn't correspond to the bending sequence diagram.

As shown in Figure 11: Although there are many steps, bending is actually not difficult. Pay attention to the broken wire, think about it and you will understand. It is very simple.

Sheet metal bending requires experience; observe how experienced craftsmen bend sheets and why they do it that way. To learn more about bending machines or bending processes, please contact our JUGAO CNC MACHINE team.