Punching VS Laser Cutting: Which Is the Better Choice?

Punching? Think of it as using a powerful stamp to cut shapes out of metal.

Laser cutting? It uses a highly focused beam of light to slice through metalwith remarkable precision. Choosing the right cutting method is crucial for yourbusiness.

What is Punching?

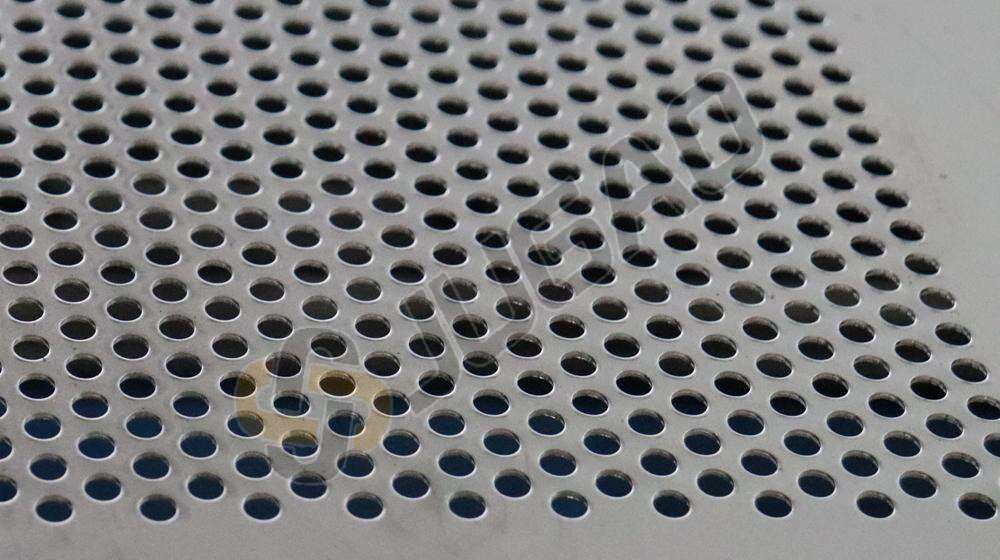

Punching uses controlled mechanical force to remove material from sheetmetal. A punching press drives a hardened steel die to punch through theworkpiece at high speed. This process can cleanly create holes, slots, andcomplex shapes in seconds.

Modern punching presses employ hydraulic or mechanical systems. The upper die(punch) descends through the material, while the lower die (die block) supportsthe workpiece. Material separation occurs when the punch penetratesapproximately 30% to 40% of the sheet's thickness.

Punching presses come in various configurations, from simple single-stationunits to complex turret systems. Turret presses can automatically rotatemultiple tools, enabling rapid pattern creation without manual die changes. CNCcontrol systems precisely position the workpiece, ensuring repeatableaccuracy.

How Does Punching Work?

The punching process systematically removes material through a shearingsystem. An operator positions the metal sheet on the press table, aligning itwith a guidance system. The punch descends at a controlled speed, typicallybetween 100 to 500 strokes per minute.

The punching process occurs in three distinct stages:

Penetration Stage: The punch contacts and begins to enter the material.

Shearing Stage: The material fractures as the punch reaches a criticaldepth.

Stripping Stage: The punch retracts, while a stripper plate prevents thematerial from sticking.

Tool selection determines hole quality and production efficiency.Well-maintained, sharp tools produce clean holes with minimal burrs. Dieclearance (the gap between punch and die) should match the material's thicknessand type for optimal results.

What Are the Advantages of Punching?

Punching offers numerous advantages, making it the best choice for certainmachining tasks. Key benefits include:

High Speed: Modern punching presses, like turret punch presses, can process500 to 1000 holes per minute—significantly faster than laser cutting—enablingrapid production of large part quantities.

Cost-Effectiveness for High Volumes: Punching becomes very cost-effectivefor large production runs. After the initial tooling cost, the per-part cost isvery low. It also removes only the necessary metal, minimizing materialwaste.

Versatility in Forming: Punching isn't limited to punching holes. It canalso create dimples, louvers, raised designs, and other formed features in asingle step. Some tools can perform multiple actions simultaneously, reducingprocessing time.

Consistency and Repeatability: Each part is identical. As it usesmechanical force without generating heat, there are no thermal alterations tothe metal's internal structure. It can easily maintain part geometry within±0.002 inches.

What Are the Disadvantages of Punching?

Despite its many benefits, punching has some limitations to consider:

High Initial Tooling Cost: Punching tools can be expensive. Custom dies forspecific patterns can cost between $500 and $5000, depending on size andcomplexity. For small production runs, recouping these high costs can bechallenging.

Material Limitations: Punching isn't suitable for all materials. Ittypically handles sheets between 0.010 inches and 0.500 inches thick, dependingon the metal's hardness. Very hard metals may require special equipment oralternative cutting methods.

Edge Quality Variation: The edges of stamped metal aren't always smooth.The final result depends on the metal type and tool condition. Some metals mayhave rough or cracked edges, potentially requiring secondary operations likedeburring.

Geometric Limitations: Punching has size constraints. Very small holesrelative to material thickness are not feasible. Creating intricate shapes orfine curves might require expensive progressive punching dies or multipleprocessing steps.

What is Laser Cutting?

Laser cutting uses a highly concentrated beam of light to melt, burn, orvaporize material along a predetermined cut path. The laser beam is extremelyfocused, allowing for high-precision cuts, though it causes a smallheat-affected zone (HAZ) in the immediate area.

CO2 lasers are commonly used for cutting sheet metal, emitting infrared lightat a 10.6-micron wavelength. However, fiber lasers are increasingly popular dueto superior cutting performance and higher energy efficiency.

The cutting process involves several simultaneous actions. The laser heatsthe metal until it melts or vaporizes. A assist gas, such as oxygen, nitrogen,or air, then blows the molten material away from the kerf. CNC machinery movesthe laser head along a precise path defined by the digital design.

Laser cutting can handle sheet metal from as thin as 0.005 inches up to 6inches thick, depending on laser power and material type.

Understanding the Laser Cutting Process

Laser cutting starts with preparing a Computer-Aided Design (CAD) file.Nesting software arranges parts on the sheet to minimize waste. CNC programmingthen converts the geometry into machine-readable instructions.

The Beam Delivery System transmits laser energy from the source to thecutting head. Fiber optic cables or mirrors guide the beam while maintainingfocus. A focusing lens concentrates the energy into a spot typically 0.006 to0.012 inches in diameter.

The Motion System positions the cutting head with extreme precision. Linearmotors or servo drives achieve positioning accuracy within ±0.001 inches.Multi-axis synchronized movement allows for high-speed cutting of complexcontours.

Process Monitoring ensures consistent cut quality. Sensors detectbreakthrough points, monitor assist gas pressure, and track beam alignment.Automatic height control maintains the optimal focal position relative to thematerial surface.

What Are the Advantages of Laser Cutting?

Laser cutting is renowned for its high precision and clean results, offeringseveral benefits for modern manufacturing:

High Precision and Accuracy: Laser cutting achieves tight tolerances,typically around ±0.002 inches, with minimal taper. It can produce highlyaccurate, intricate shapes without the need for expensive physical tooling.

Design Flexibility and Quick Turnaround: Design changes are implementedsimply by updating the machine program, often within minutes. This makes lasercutting ideal for prototyping and low-to-medium volume production.

Material Versatility: Laser machines can cut a wide range of materials,including metals, plastics, ceramics, and composites. They deliver high-qualityresults on both thin and thick sheets of steel.

Excellent Edge Quality: Edges are typically very smooth, often eliminatingthe need for secondary finishing. With correct settings, cuts are straight andclean with a small heat-affected zone.

No Tool Wear: As the laser beam doesn't physically contact the material,there is no tool wear. This eliminates the cost and downtime associated withreplacing punch and die sets.

What Are the Main Disadvantages of Laser Cutting?

While known for precision, laser cutting has some drawbacks that can impactproduction time, cost, and material selection:

Slower for Simple Shapes: Laser cutting is generally slower than punchingfor producing simple shapes and standard holes. For intricate designs requiringmultiple passes, overall speed decreases, which can be problematic forhigh-volume production with tight deadlines.

High Operational Costs: Laser cutters have high energy consumption andrequire regular maintenance. Components like laser tubes, lenses, and mirrorswear out and need replacement. The cost of assist gases like nitrogen or oxygenalso adds to operational expenses.

Material and Thickness Limitations: Cutting capabilities are limited bymaterial type and thickness, which depend on laser power. Reflective materialslike copper and aluminum can be challenging to cut. Very thick sections mayrequire multiple passes or specialized equipment.

Heat-Affected Zone (HAZ): The heat input during cutting can alter themetallurgical properties near the cut edge, potentially affecting the part'sperformance. Some applications may require post-processing to address theHAZ.

What is the Difference Between Punching and Laser Cutting?

The primary difference lies in how material is removed and thecharacteristics of the resulting cut.

Punching uses powerful mechanical force to shear the material. This creates acharacteristic edge with both sheared (smooth) and fractured (rough) areas. Theremoved material piece (slug) is completely pushed out of the main sheet.

Laser cutting, conversely, uses thermal energy to remove material. The lasermelts or vaporizes metal along the cut line, creating a smooth, narrow gap knownas the kerf and leaving a heat-affected edge. Unlike punching, laser removesmaterial in a continuous flow, enabling the creation of highly complex shapesthat are impossible with punching.

| PUNCHINGVS LASER CUTTING | ||

| PUNCHING | Vs | LASERCUTTING |

| SMOOTH,WORKHARDENED | EDGEQUALITY | SUPERIORFINISH |

| QUICKFORSTANDARD HOLES | SETUPTIME | MODERATEPROGRAMMINGTIME |

| HIGHVOLUMEPRODUCTION | BESTFOR | COMPLEXSHAPES&PROTOTYPES |

| 1000+HITS/MIN | SPEED | VARIABLESPEED |

| BRACKETS,PANELS,ENCLOSURES | IDEALAPPLICATIONS | DECORATIVEPARTS,PROTOTYPES |

Comparison table of punching and laser cutting:

| Category | Punching | LaserCutting |

| Speed | 500-1000holes/minute | CuttingSpeeds 100-2000 IPMM |

| PlatformAccuracy | ±0.002" (typical) | Achievable±0.001" |

| SetupTime | Toolingchanges required | ProgrammedChanges Only |

| MaterialThickness | Typicalvalues: 0.010"-0.500" | 0.005"-6.000"Possible |

| EdgeQuality | Suitablefor use with appropriate tooling | ExcellentResults After Optimization |

| OperatingCost | Lowunit price | ModeratePart Size |

| MachiningCost | $500-$5000per tool | NoTools Required |

| DesignFlexibility | Subjectto tooling limitations | UnlimitedGeometric Freedom |

| Heat-AffectedZone | None | ExtremelySmall, Yet Presence |

| MaterialWaste | Minimum | OptimizedNesting Reduces Waste |

From a manufacturing perspective, punching excels at high-speed creation ofdiscrete features like holes and simple shapes, while laser cutting offerssuperior geometric flexibility for complex contours and intricate details.

How to Choose: Punching or Laser Cutting?

The choice between punching and laser cutting depends on projectrequirements. Factors like volume, geometric complexity, material type, andoverall cost all play significant roles.

1. Based on Production Volume

For high-volume production runs (over 1000 parts), punching is often thebetter choice due to its speed and lower per-part cost. For testing designs orsmall batches, laser cutting is more flexible and cost-effective, as it avoidshigh tooling expenses.

2. Based on Part Size and Design

Part geometry is crucial. Punching is ideal for simple holes and basicshapes. If your design involves complex contours, fine details, or requires veryhigh precision, laser cutting is the superior option.

3. Based on Material Type

Both methods work well with thin sheet metal (under 0.125 inches). Forthicker materials, laser cutting generally performs better. Exercise cautionwith highly reflective metals like copper or bare aluminum, as they can posechallenges for laser cutters.

4. Based on Cost and Efficiency

To find the best value, consider the total cost—not just machine time.Punching may require costly custom tooling and setup time. Laser cutting mightbe slower per part but often requires fewer secondary operations. The betterchoice depends on your specific production requirements.

Punching is ideal for producing large quantities of parts with simple shapes.It's fast and offers a low per-part cost, especially for basic geometries likecircles or squares. Laser cutting is better suited for large, complex shapes,even for lower quantities. It provides greater precision and flexibility, albeitat a slightly higher cost per part.

The optimal choice ultimately depends on the number of parts needed, designcomplexity, and budget. Many savvy manufacturers utilize both methods, selectingthe best process for each specific job. Combining punching and laser cutting canoften yield the best overall results.