Optimizing Press Brake Productivity: A Performance Assessment Framework

In today's competitive metal fabrication landscape, press brake productivity directly impacts operational profitability and market responsiveness. This in-depth analysis presents a systematic approach to evaluating and enhancing press brake performance, combining technical metrics with operational best practices to drive measurable improvements in your manufacturing processes.

Critical Productivity Determinants for Press Brake Operations

1. Operational Efficiency Metrics

Modern press brake performance assessment requires monitoring three key indicators:

Cycle Time Analysis: Track actual bending cycles against theoretical machine capacity

Quality Yield Rates: Measure first-pass yield versus rework percentages

Energy Consumption Patterns: Monitor power usage per production unit

Advanced CNC models now incorporate built-in analytics dashboards that provide real-time OEE (Overall Equipment Effectiveness) scores, enabling data-driven decision making.

2. Workflow Optimization Strategies

Workflow Optimization

Implement lean manufacturing principles to eliminate non-value-added activities:

SMED (Single-Minute Exchange of Die) Techniques: Reduce tooling changeovers to under 10 minutes

Material Flow Mapping: Reorganize shop floor layouts to minimize handling distances

Digital Job Tracking: Implement MES systems for real-time production monitoring

These methods typically achieve 25-40% improvements in operational throughput.

3. Human Capital Development

Operator Training

Develop a tiered skills certification program covering:

Basic machine operation (Level 1)

Advanced troubleshooting (Level 2)

Process optimization (Level 3)

Cross-training operators on multiple machines creates workforce flexibility that can reduce downtime by up to 30% during shift changes or absences.

Advanced Techniques for Performance Enhancement

1. Predictive Maintenance Systems

Transition from scheduled maintenance to condition-based monitoring:

Vibration analysis for ram alignment

Hydraulic fluid quality sensors

Thermal imaging of electrical components

These technologies can predict 85% of potential failures before they cause unscheduled downtime.

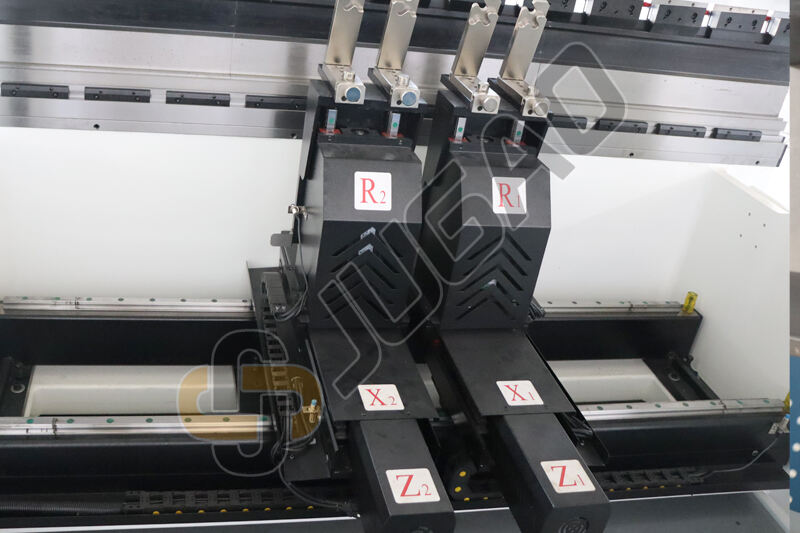

2. Smart Automation Integration

Automation Solutions

Evaluate automation opportunities across three levels:

Basic Automation: Automatic tool changers

Intermediate Systems: Robotic material handling

Advanced Solutions: AI-driven adaptive bending

ROI analysis typically shows payback periods of 12-18 months for comprehensive automation packages.

3. CNC Programming Optimization

Implement advanced programming techniques:

Nesting Algorithms: Maximize material utilization

Collision Simulation: Virtual testing of bending sequences

Cloud-Based Libraries: Centralized program storage and version control

These methods typically reduce programming time by 40% while improving process reliability.

Expert Q&A: Solving Press Brake Productivity Challenges

Q: What's the most impactful first step to improve press brake productivity?

A: Conduct a comprehensive time-motion study to identify your largest productivity bottlenecks before implementing solutions.

Q: How frequently should we benchmark our press brake performance?

A: Perform quarterly productivity audits with monthly KPI tracking to maintain continuous improvement momentum.

Q: What automation investments provide the fastest returns?

A: Automatic tool changing systems typically deliver the most immediate productivity gains with relatively low implementation complexity.

Strategic Roadmap for Continuous Improvement

Develop a 12-month productivity enhancement plan:

Months 1-3: Baseline assessment and bottleneck identification

Months 4-6: Operator training and basic automation implementation

Months 7-9: Advanced process optimization and predictive maintenance

Months 10-12: Full system integration and performance validation

Leading manufacturers who follow this structured approach typically achieve:

35-50% improvement in throughput

25% reduction in material waste

20% decrease in energy costs per unit

For organizations ready to transform their press brake operations, partnering with technology providers JUGAO CNC MACHINE who offer comprehensive productivity assessment services can accelerate results while minimizing implementation risks. The most progressive manufacturers are now combining these mechanical improvements with digital twin technology to simulate and optimize processes before physical implementation.