Optimizing Press Brake Performance with the DELEM DA-66T Control System

The DELEM DA-66T represents a technological leap in press brake control systems, delivering unmatched precision and operational efficiency for modern metal fabrication. This advanced CNC controller combines intuitive operation with powerful programming capabilities to transform your bending operations.

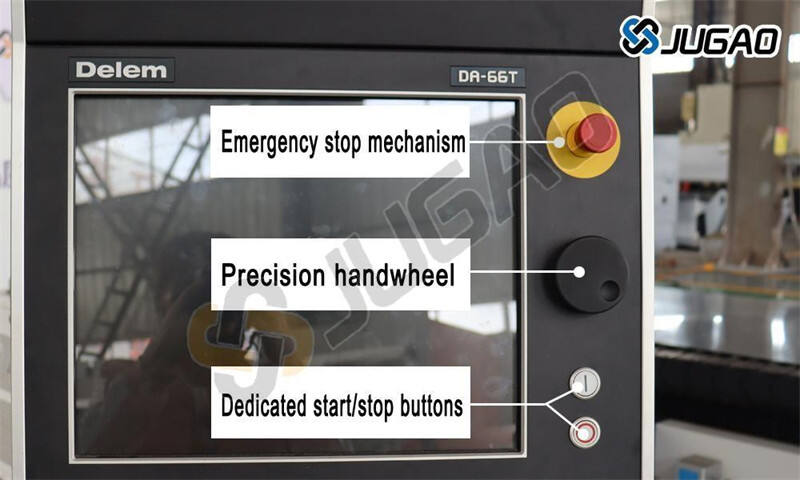

Mastering the Control Unit Interface

As the operational nucleus of your press brake, the DA-66T control unit features a sophisticated yet user-friendly touchscreen interface complemented by essential physical controls:

Emergency stop mechanism for immediate safety response

Precision handwheel for manual axis adjustment (Y-axis and backgauge)

Dedicated start/stop buttons for seamless operation control

Dual USB ports for expanded connectivity and data management

The system's modular design allows for custom function key integration based on specific manufacturer configurations.

Intuitive Touchscreen Navigation

The DA-Touch interface organizes workflow into logical sections:

1. Title Panel: Displays critical operational data including active programs, bend sequences, and machine status indicators

2. Information Panel: Provides real-time visualization and functional controls for selected operations

3. Navigation Panel: Features one-touch access to nine primary operational modes through icon-based controls

Key operational modes include:

Product Programming: Create and manage bending programs

Graphical Editing: Develop 2D/3D product designs with touch gestures

Tool Configuration: Set up and modify tool libraries

Bend Sequencing: Optimize bending order and simulate operations

CNC Programming: Direct numerical control editing

Production Execution: Initiate automated bending processes

Advanced Product Programming Workflow

The DA-66T streamlines program development through a structured approach:

1. Material Setup

Configure material properties in the digital library

Establish tooling parameters for accurate bending calculations

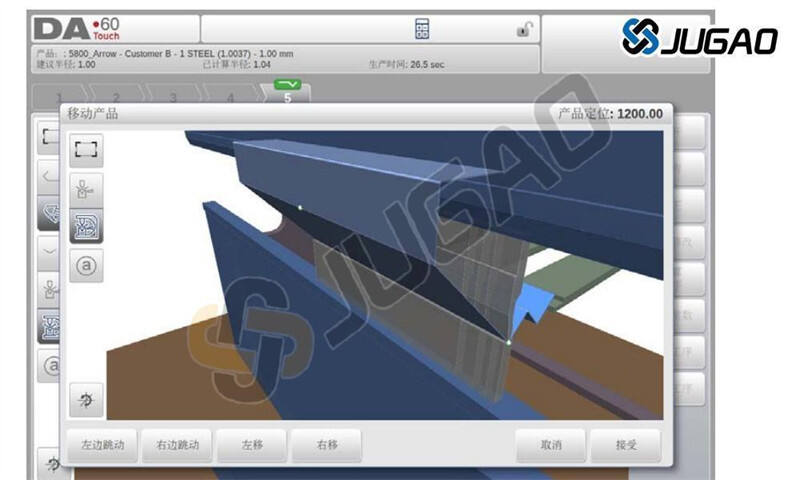

2. Graphical Design

Sketch product profiles with intuitive touch controls

Precise dimensioning through value input fields

Advanced features include:

Pinch-zoom and pan functionality

Real-time angle/length adjustment

Hemming and bumping operations

3D visualization capabilities

3. Bend Sequence Optimization

Automatic sequence generation for maximum efficiency

Interactive simulation with collision detection

Manual sequence customization

Production time estimation

4. CNC Program Finalization

Automatic program generation from graphical input

Direct numerical editing capability

Force calculation and machine parameter optimization

Enhanced Operational Features

The DA-66T incorporates numerous productivity tools:

Context-Sensitive Help System: Instant access to operational guidance

Smart Search Functionality: Rapid program/tool/material location

Advanced Input Options:

Adaptive keyboard (numeric/alphanumeric/special characters)

Multiline text editing

Integrated calculator with engineering functions

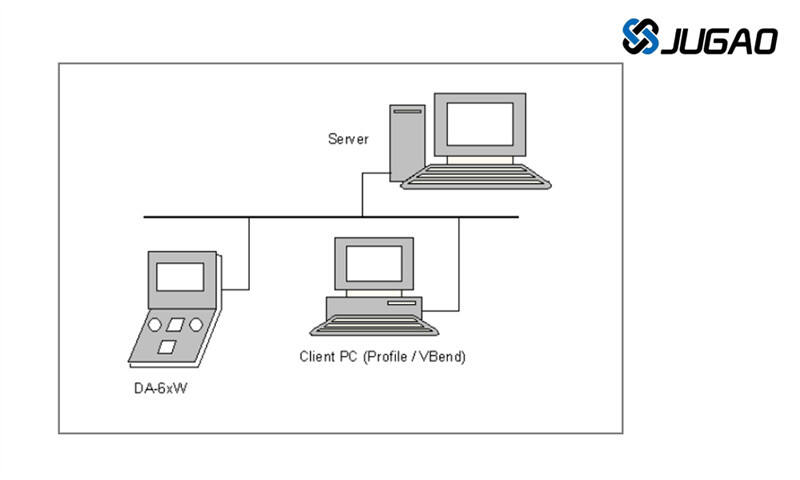

Data Management:

USB and network connectivity

Comprehensive backup/restore functionality

Security Features:

Program and machine lock functions

Customizable access codes

System Maintenance:

Software version tracking

OEM-specific function panels

Frequently Asked Questions

Q: Can the DA-66T accommodate complex custom bending operations?

A: Absolutely. The system's flexible programming environment supports fully customized bending sequences, including specialized operations like hemming and bumping.

Q: How does the DA-66T integrate with existing press brake systems?

A: Designed for seamless integration, the controller features standardized interfaces and comprehensive documentation to ensure smooth implementation with most modern press brakes.

Conclusion

The DELEM DA-66T establishes a new benchmark in press brake control technology, offering fabricators an unparalleled combination of precision, efficiency, and user-friendly operation. By leveraging its advanced features and intuitive interface, manufacturers can significantly enhance productivity while maintaining the highest quality standards in metal forming operations.

For optimal implementation and ongoing support, Please consult JUGAO CNC MACHINE to customize a system according to your specific production needs.