A lézeres vágás befolyásoló tényezői és teljesítményértékelése

A lézeres feldolgozó berendezések piacán a lézeres vágás kiemelkedő alkalmazástechnológiának számít. 2024-ben Kínában körülbelül 3000 lézeres vágógépet adtak el, ami azt mutatja, hogy egyre inkább elterjedőben van a hagyományos eszközök, mint például ollók és sajtóprés gépek helyettesítése. A lézeres jelölés széleskörű elterjedése után a nagy teljesítményű lézeres vágógépek piaca – amelyeket magas vágási sebesség, pontosság, vastag lemezfeldolgozási képesség és nagy vágási formátumok jellemez – jelentős bővülés előtt áll.

A lézeres vágást befolyásoló főbb tényezők

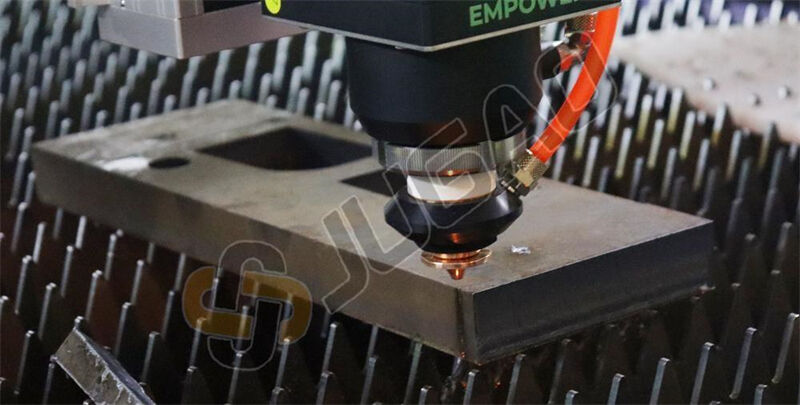

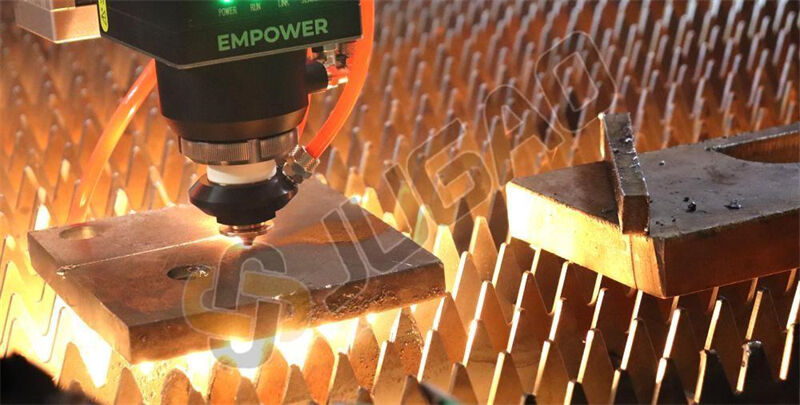

A lézeres vágás során a lézerforrás által kibocsátott lézersugár a vágófej lencserendszerén keresztül kollektálódik és egy finom pontra (fókuszpont) fókuszálódik. A kezelőnek biztosítania kell, hogy a lézersugár pontosan igazodjon a fúvókához, valamint a fúvóka és az anyag közötti távolságot az anyag vastagságának megfelelően kell beállítani. A fúvókából nagy nyomású gáz áramlik ki, amely együttműködik a lézersugárral a vágási folyamat befejezéséhez. A legfontosabb befolyásoló tényezők a következők:

1.Fókuszpont Átmérője

Egy kisebb átmérő keskenyebb vágást eredményez, de korlátozza a vágási vastagságot.

Egy nagyobb átmérő lehetővé teszi a vastagabb anyagok vágását, de szélesebb vágást eredményez.

2.Fókuszpont Pozíciója

Meghatározza a folt méretét az anyag felületén és a vágás alakját.

Az optimális pozíció az anyag típusától és vastagságától függ.

3.Lézer Teljesítmény

Befolyásolja a maximális anyagvastagságot, amit vágni lehet.

Befolyásolja a feldolgozási hatékonyságot és a hődeformáció mértékét.

4.Vágási sebesség

A teljesítménnyel és a gáz áramlási sebességével való egyensúlyban kell lennie.

Túl lassú: hiányos vágások vagy túlzott szélek képződése.

Túl gyors: csökkent vágási minőség vagy a behatolás képtelensége.

5.Szórófej átmérője

A kisebb szórófejek ideálisak vékony anyagokhoz.

A nagyobb szórófejek jobban alkalmazhatók vastag anyagoknál.

6.Segédgáz

A gáz tisztasága hatással van a szélképződésre és a vágási felület oxidációjára.

A vékonyabb anyagokhoz nagyobb gáznyomás szükséges az eredményes vágáshoz.

7.Beam mód

Egymódú sugarak (1500 W alatt) kiválóan alkalmasak vékony lemezvágásra.

Többmódú sugarak (1500 W felett) nagyobb foltméretet és egyenletes energiaeloszlást biztosítanak, így alkalmasak vastag lemez vágására.

Lézervágási teljesítménymutatók

A lézervágó berendezések kielégítik az iparágak összetett igényeit, mint például a gépjárműipar, a repülőgépipar, az egészségügy, a műanyagipar, az elektronika és a textilipar, magas sebesség, pontosság és minőség biztosításával. A lézervágás hatékonysága az alábbi szempontok szerint értékelhető:

1.Felületi érdesség

A vágási él csíkozott; sekélyebb csíkozottság utal alacsonyabb érdességre és simább felületre.

Általában vékonyabb anyagok eredményeznek alacsonyabb érdességet.

A nitrogén vagy argon gáz simább vágást eredményez oxigénhez képest.

2.Vágás merőlegessége

A fókuszált nyaláb divergenciája miatt a foltméret változhat a anyagvastagság mentén, ami eltérést okoz a tökéletes 90°-os szögtől.

Vékonyabb anyagok és magasabb nyalábminőség javítja a merőlegességet.

Az anyagvastagsághoz viszonyított fókuszpont helyzete is kritikus szerepet játszik.

3.Szegélyképződés

A nagy minőségű vágásnak szegélymentesnek kell lennie a posztprocesszálás minimalizálása érdekében.

A szegélyeket a folyamatparaméterek, az anyagtípus és a nyalábminőség befolyásolja.

4.Hődeformáció

Mint hőtechnológiai folyamat, a lézervágás elkerülhetetlenül anyagdeformációt okoz.

A deformáció minimalizálása különösen a vékony anyagok esetében kritikus.

Nagyobb vágási sebesség, keskenyebb rések és magasabb gázáramlási sebesség csökkenti a deformációt.

Alkalmazások és felszerelések

A lézersugaras vágás széles körben alkalmazott precíziós feladatokra, például:

Rézötvözet finomvágása.

304-es rozsdamentes acél vágása.

Szárazacél megmunkálása.

Például a JUGAO Laser 500W–3000W egymódusú folyamatos hullámú szálkábelei vízhűtéssel rendelkeznek, nagy teljesítményt nyújtanak, kiváló sugárt minőségűek, karbantartásmentesen működnek, valamint magas elektrooptikai hatásfokkal rendelkeznek. Ezek a lézerek ideálisak rozsdamentes acél, szénacél, alumínium és réz vágásához, hegesztéséhez és fúrásához, alkalmazási területeik közé tartozik a lemezalkatrész-gyártás, fémfeldolgozás, háztartási gépek gyártása és autóipari termelés.

A JUGAO CNC MACHINE fő termékei laser-vágó gépek, CNC hidraulikus hajlító gépek, laser-zúzó gépek, vágó gépek és csövegyenesítő gépek stb., amelyeket lapos acélprocesszorozás, karosszerék, fémes áramkörök, világítás, mobiltelefonok, 3C, konyhaeszközök, fürdőszoba, autószerelési részek és fémipari alkalmazásokban használnak. Online konzultációra üdvözöljük a gép-információkat illetően.