How can I improve the processing efficiency of an electro-hydraulic servo press brake?

When installing an electro-hydraulic servo press brake, ensure that the wiring connections are secure and that all components are operating in harmony. A daily inspection is recommended before starting the machine to ensure processing accuracy and stability.

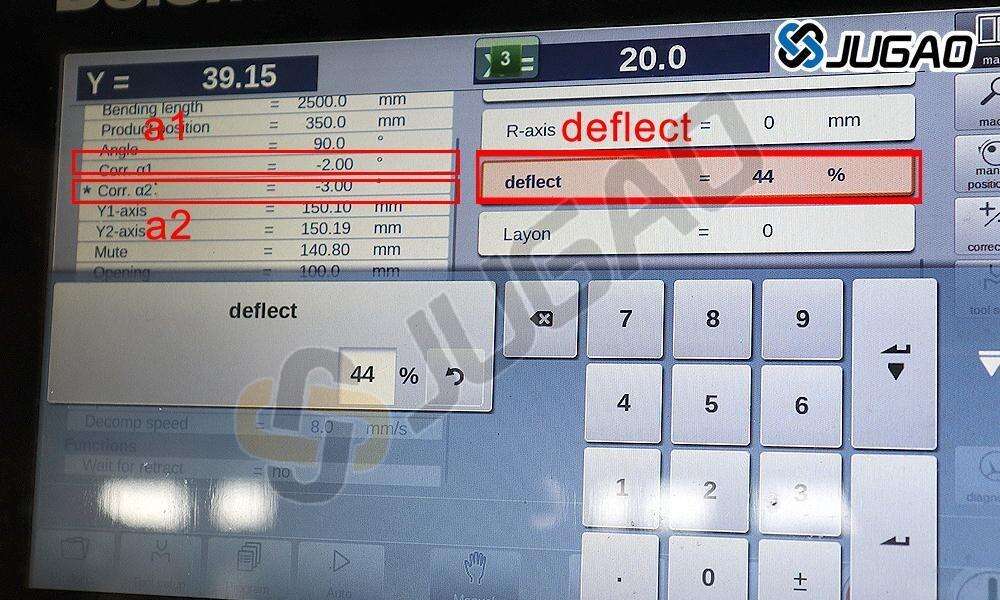

Electro-hydraulic servo CNC press brakes are typically equipped with an angle compensation function, which effectively corrects deviations during processing and significantly improves forming accuracy. Operators should strictly adhere to processing specifications, wear designated workwear and protective equipment, and ensure that processing is completed safely.

When processing metal materials, it is imperative to comply with installation process standards and strictly follow equipment operating requirements. Processing accuracy directly impacts the final installation and performance of the material. Electro-hydraulic servo CNC press brakes are specialized for bending materials. Users can pre-set parameters and then feed the material for processing, allowing for rapid completion of production tasks.

How can I resolve oil leakage issues in an electro-hydraulic press brake?

The hydraulic cylinder of an electro-hydraulic press brake primarily consists of a piston rod, chuck, cylinder body, and ball screw. Oil leakage is usually caused by aging or deformation of the piston rod seal and the seals within the hydraulic cylinder. A typical press brake hydraulic cylinder consists of a worm gear mechanism, with the worm gear connected to the cylinder piston rod via a leadscrew. Repairs require disassembly of this assembly, a process that requires assistance from equipment such as a crane or forklift, making it difficult and risky. Lifting the ball screw should be done slowly to avoid damaging the piston rod with excessive force.

Disassembly reveals multiple seals installed on the inner and outer walls of the piston rod, including dust seals, O-rings, and sealing rings. The main seal is the most critical, while the remaining seals generally do not require replacement unless they are severely damaged. After replacing the seal, external tools can be used to assist with cylinder installation.

The most direct way to resolve oil leakage in electro-hydraulic CNC press brakes is to remove and replace the seals. It is recommended to use durable sealing materials to ensure the hydraulic cylinder maintains its sealing properties long after repair and prevent recurring leaks.