Laserlõiketerade suuruste üldine klassifitseerimine

Tööstusliku klassi laser süsteemi kategooriatsoon

Laserlõikeseadmed on süsteemselt jaotatud kolme peamisse kategooriasse, lähtudes toimimisvõimest ja füüsilistest mõõtudest. Selline klassifikatsiooni raamistik võimaldab täpset vastavust seadme võimete ja konkreetsete tööstuslike nõuete vahel erinevates tootmisulatustes.

1. Kompaktne täppislasersüsteemid

Tehnilised kirjeldused:

Tööpiirkond: 300×200 mm kuni 600×450 mm (12"×8" kuni 24"×18")

Laseri võimsus: 30 W–100 W (CO₂/kiud)

Asendustäpsus: ±0,01 mm

Pindala: <1,5 m² integreeritud suitsuimega

Täiendavad funktsioonid:

Kõrge eraldusvõimega galvanomeeternihe (kuni 5000 dpi)

Õhu jahutusega laserallikad energiasäästuks

Puuteekraaniga HMI koos erialase disainitarkvaraga

Automaatne fookuse reguleerimine (±0,1 mm)

Sihipraktikad ja rakendused:

| Tööstus | Tüüpilised rakendused | Tehnilised eelised |

| Joonestus ja valmistamine | Mikrogravüür, hõbe ja hinnaliste metallide lõikamine | 20 mikroni täppide suurus keeruliste detailide jaoks |

| Elektroonika | PCB depaneling, mikrokomponentide valmistamine | Vibratsioonivaba graniitpind |

| Meditsiiniseadmed | Kirurgiliste instrumentide märgistamine | Class1 puhtsusklassi ruumiga ühilduvus |

| Haridus | Inžennerprototüüpimine | Turvalisuslukud ja vähendatud võimsuse režiimid |

2. Keskma otsa tootmisega laserlõikurid

Tehnilised kirjeldused:

Tööpiir: 600×450 mm kuni 1200×900 mm (24"×18" kuni 48"×36")

Laseri võimsus: 100W-300W (Kiud/Ketas)

Lõikamise kiirus: kuni 20 m/min (1 mm kerge teras)

Pindala: 3-5 m² koos materjalikäitlemise süsteemiga

Täiendavad funktsioonid:

Kahe laseriga hübriidkonfigureerimise valikud

Automaatne duši vahetamise süsteem

Reaalajas kiirguse diagnostika

Ennustava hoolduse liides

Tööstuslikud rakendused:

Autotööstuse teise astme tarnijad:

Keelpilli prototüüpimine

Sisustuse komponentide valmistamine

Puhusakkude tootmine

Müügikoha ekraanid:

Mitmekihilised akrüülikonstruktsioonid

Metall-puu komposiitstruktuurid

Kiirendatud vektorkärme

Tekstiilitööstuse täiustatud tootmine:

Tehnilise kangastöötlemine

Komposiitmaterjali paigaldamine

Automaatne mustri paigutamine

3. Raske töökindlusega tööstuslaserplatvormid

Tehnilised kirjeldused:

Tööpiir: 1200×900 mm kuni 2500×1500 mm+ (48"×36" kuni 100"×60"+)

Laseri võimsus: 300 W–15 kW (kiud/CO₂)

Materjali maht: kuni 50 mm kerge teras

Pindala: 8–15 m² perifeersüsteemidega

Täiendavad funktsioonid:

Vardasüsteemi liigutusjuhtimissüsteemid (0,05 mm/m täpsus)

Mitme paleti automaatne laadimine

Adaptiivse lõiketera tehnoloogia

Integreeritud kvaliteedikontrolli moodulid

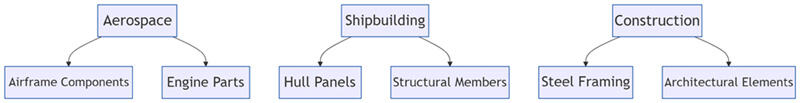

Raskurahanduse rakendused:

Tehniline võrdlusmaatriks:

| Parameeter | Kompaktne | Keskmine | Tööstus |

| MaxSheet paksus* | 3mm | 10mm | 50mm |

| Tavaline tolerants | ≤0,02 mm | ≤0.05mm | ≤0.1mm |

| Võimsustarbe | 2-5 kVA | 10-20kVA | 30-100kVA |

| Automatiseerimise tase | Käsiraamat | Poolautomaat | Täisautomaat |

| Tsükliaeg (1m2) | 2-4 tundi | 30-60 min | 5-15min |

*Kergele terasele O₂ abiga

Valikumeetodika

Nelja sammu otsustusraamistik:

1. Materjali profiilianalyys

Tehke metallurgiline testimine

Mõõta soojusjuhtivust

Määrata peegeldusindeks

2. Tootmismahu hindamine

Arvutage aastast läbipääsu nõuded

Hindage töövahetuste mustreid

Projekteerige kasvusenaareid

3. Seadme auditi

Mõõda saadavalolev põrandapind

Kinnita elektrivarustuse infrastruktuur

Hinda materjalide liikumise teed

4. Omanduskulude kogumudel

Põhivaradega seotud kulud

Kulutusmaterjalide kulu

Hooldustöö tundide arv

Energia kulutus

Uue tehnoloogia integreerimine

Nutikate tootmisseadmete funktsionaalsus:

Internet of Things (asjade interneti) abil võimaldatav jõudluse jälgimine

Pilveteenuses põhinev tööde ajakava koostamine

Täiendatud reaalseisu hooldusjuhendid

Masinõppe protsessi optimeerimine

Keskkonnasäästlik toimimine:

Energia taaskasutuse süsteemid

Suletud veesoojendus

Purilise filtreerimine >99,97%

Müra vähendavad korpused

See klassifikatsioonisüsteem võimaldab tootjatel:

Vähendada seadmete valikuaega 40–60%

Optimeerida kapitalikulu ROI-d

Vähendage tootmisahelate kitsendusi

Tehnoloogiainvesteeringud tulevikku silmas pidades

Parimate tulemuste saavutamiseks pidage nõu laseri rakendusinseneridega, et läbi viia täielik tootmeanalyys enne seadmete tehniliste näitajate kinnistamist.