Enhancing Bending Accuracy with DELEM DA-53T Machine Mode

Enhancing Bending Accuracy with DELEM DA-53T Machine Mode

In precision metalworking, achieving consistent and exact results is critical—this is the core capability delivered by the DELEM DA-53T Machine Mode. If you are looking to understand how this advanced function enhances operational precision in press brake applications, you’ve found the right resource.

This article examines how the DELEM DA-53T Machine Mode improves bending accuracy through enhanced control and repeatability. You will gain practical insights into applying this technology to elevate production quality and maintain tight tolerances across batches. Whether you currently operate DELEM systems or are evaluating performance upgrades, the following overview will demonstrate the tangible advantages of integrating the DA-53T Machine Mode into your metalforming processes.

Introduction

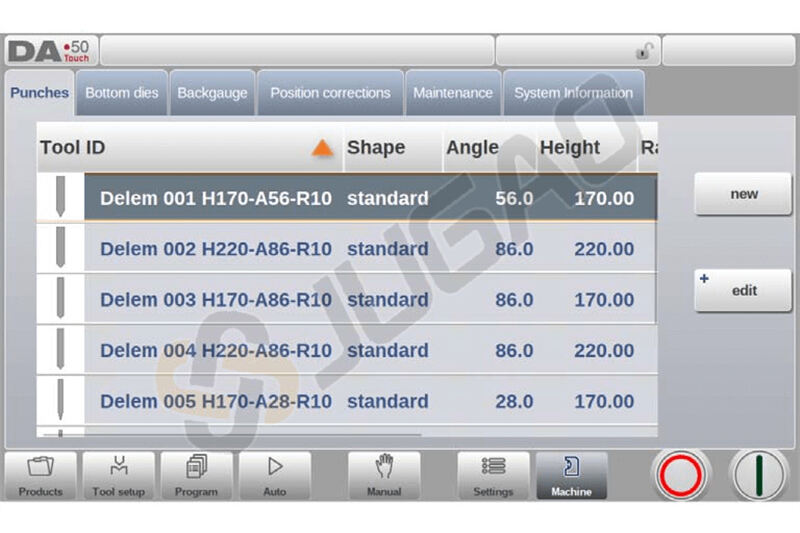

By tapping the navigation button Machine the control is switched to Machine mode.

The DELEM DA-53T Machine Mode, easily accessible through the navigation panel, allows you to configure machine settings and characteristics that impact calculations and behavior.

These settings are organized into several tabs for easy navigation. To adjust any item, simply tap the desired tab. If more tabs exist than can be displayed at once, you can drag horizontally to view and select all available options.

Optimized Backgauge Functionality

The DELEM DA-53T enhances precision in backgauge settings by considering dimensions like backgauge finger size, R-axis, and X-axis movements. Through DELEM DA-53T Machine Mode, it calculates potential workpiece-backgauge collisions and allows R-axis offset adjustments for optimal positioning outside the die safety zone.

Strategies for Maximizing Backgauge Accuracy with the DELEM DA-53T:

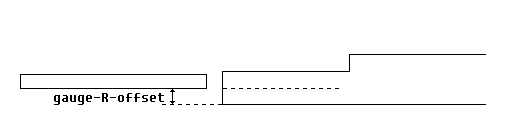

Gauge R offset: An offset value for the R-axis can be set if the backgauge is positioned against the sheet edge and the X-axis position is outside the die safety zone. A negative value gives a lower backgauge position. This offset is only valid for gauge position 0.

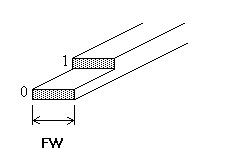

Finger Width: Use the Machine Mode to set precise finger dimensions, especially with an automatic Z-axis, for enhanced alignment and collision prevention.

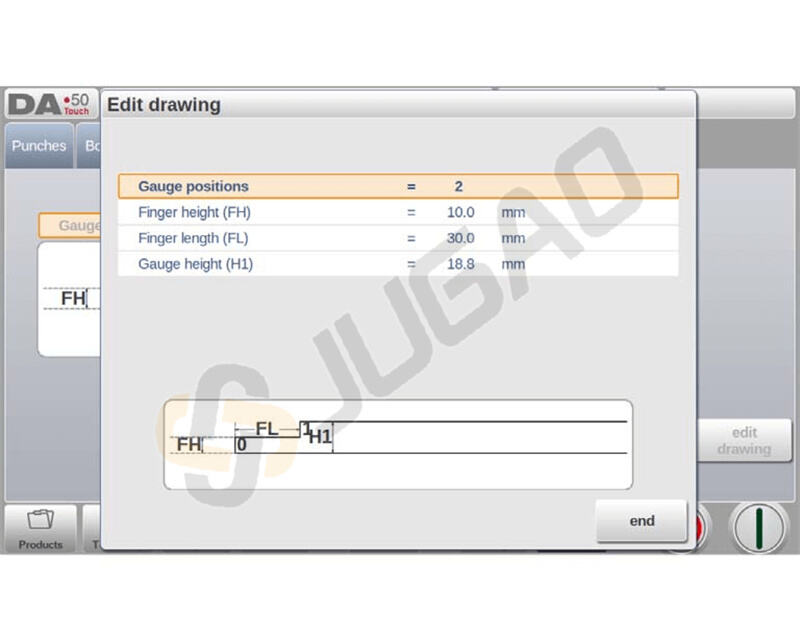

Tap “Edit Drawing” to display the backgauge drawing, allowing you to program the dimensions of the backgauge finger within the DELEM DA-53T Machine Mode.

The parameters provided describe the dimensions and lay-on positions of the backgauge. The number of parameters required will depend on the gauge positions you program. As more gauge positions are set, additional parameters will be available, and the illustration at the bottom of the screen will update accordingly.

Gauge Positions: Utilize up to four customizable gauge positions, allowing the system to adapt finger geometry for each scenario.

Finger Parameters: Set finger height (FH), length (FL), and gauge height (H1) accurately to maintain precise lay-on positions.

The DELEM DA-53T Machine Mode significantly boosts backgauge accuracy and efficiency in sheet metal operations.

Advanced Position Corrections

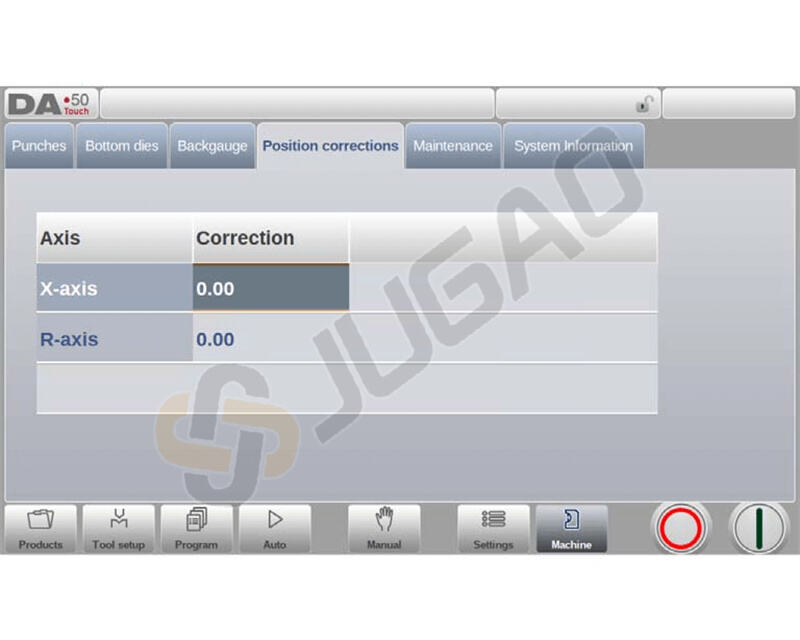

The DELEM DA-53T controller offers tools for correcting positional errors when the actual mechanical axis position doesn’t match the displayed value. This is achieved by adjusting the position correction parameter:

If the displayed value is 250 and the actual position is 252, set the correction to -2.

If the displayed value is 250 and the actual position is 248, set the correction to +2.

Corrections apply to all auxiliary axes and should be used temporarily. In DELEM DA-53T Machine Mode, ensure normal corrections are zero to maintain precision.

Best Practices for High-Precision Operations:

1. Regular Calibration: Calibrate frequently to minimize the need for corrections.

2. Temporary Corrections: Use position corrections as a short-term fix. Persistent issues may require service.

3. Zeroing Corrections: Aim to keep corrections at zero during normal operation.

4. Documentation: Record and monitor corrections to identify patterns or maintenance needs.

By following these guidelines, you can optimize machine precision and performance.

Proactive Maintenance and System Monitoring

The DELEM DA-53T Machine Mode streamlines maintenance management with critical tools like the machine hour counter and stroke counter for monitoring usage.

These features guide regular maintenance schedules and prevent unexpected breakdowns. The diagnostic mode, which can be activated for in-depth troubleshooting, is available through a special code provided by the manufacturer.

Additionally, the Lock Screen function aids maintenance without altering settings, and the system can create a .dat-file to store important data for service support.

System Information and Troubleshooting

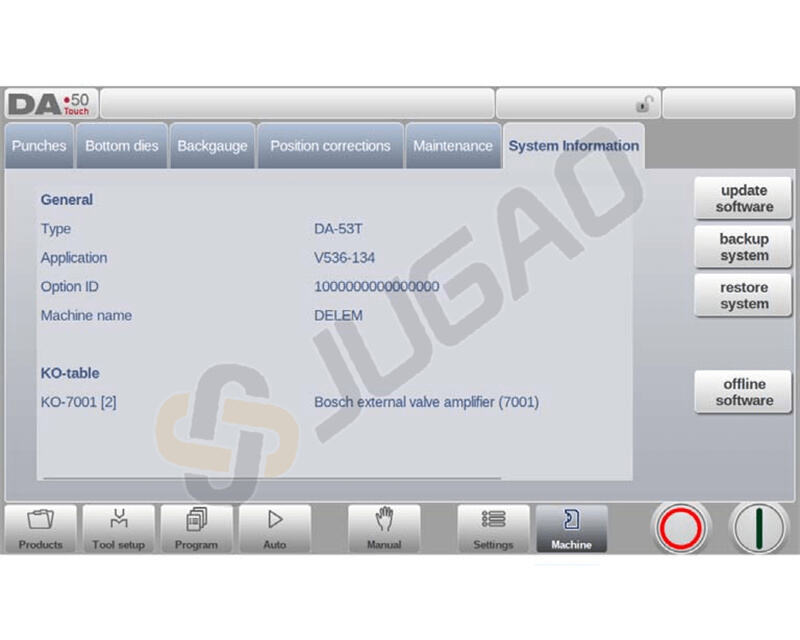

In the realm of enhanced problem-solving, utilizing system information is crucial. On the DELEM DA-53T Machine Mode, system information can be accessed for a comprehensive overview of the control system, including version details of the software and the IDs of installed modules. Additionally, information about OEM-specific files can also be obtained, which is invaluable for service and maintenance purposes.

This screen shows detailed information about the control system. This information is useful for service purposes.

Application: The version of the current application

Option ID: The unique option ID of the control

Sequencer: The version number of the running sequencer

Delem.def: The version number of the running delem.def file

Update software

For improved machine accuracy, keeping software updated is essential. Within the DELEM DA-53T Machine Mode, users can find software update functionalities that enable the installation of update sets directly from a USB stick.

Backup system and Restore system

Moreover, the machine mode also offers options for backup and restoration. Users can create a complete system backup that includes Delem software, OEM-specific data, and user files, which is saved as a uniquely timestamped file on a USB stick.

Conclusion

In summary, the DELEM DA-53T Machine Mode delivers measurable improvements in press brake accuracy through precise system monitoring, streamlined software maintenance, and reliable data management. These integrated features work systematically to maintain peak operational performance while minimizing production interruptions.

To further explore how the DELEM DA-53T can optimize your specific applications or to receive tailored technical guidance, we welcome you to consult our specialists. Implementing proper configuration and scheduled maintenance is essential for extending equipment service life and sustaining process efficiency. By following prescribed operational protocols and performing regular system checks, you can effectively reduce unplanned downtime and enhance overall output.

For project-specific assistance or additional technical information, please contact our support team or access our expanded library of operational resources and system documentation.