×

×

Hey there! Do you know what metal press and bend is? It’s a neat way to produce things out of metal. Today, we're going to take a quick primer on Metal Press Forming, how it works, and how it deals with JUGAO.

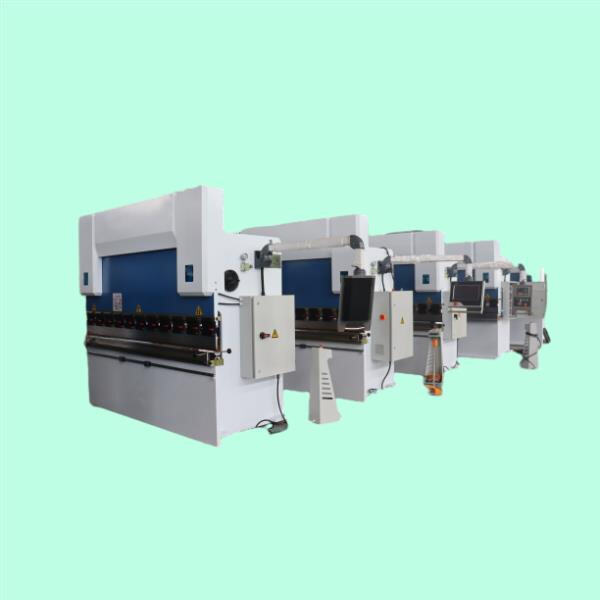

Metal press forming is a technology used to change the shape of metal by use of a press, the machine tool that forms the metal to the desired shape. This presses the metal into various shapes and sizes. It’s like cutting cookies with a cookie cutter, except with metal! This process goes on to generate parts of cars, kitchen gadgets, and even toys. It is crucial to making many types of products.

So, how does it work? First, there is the piece of metal in the press machine. Next, the machine applies a great deal of pressure to force the metal into the desired shape. This can occur either all at once, or by pressing the metal a few times until it is perfect. One major plus of metal press bender is that it serves to produce many products rapidly. It also ensures that each product is consistently the same shape and size.

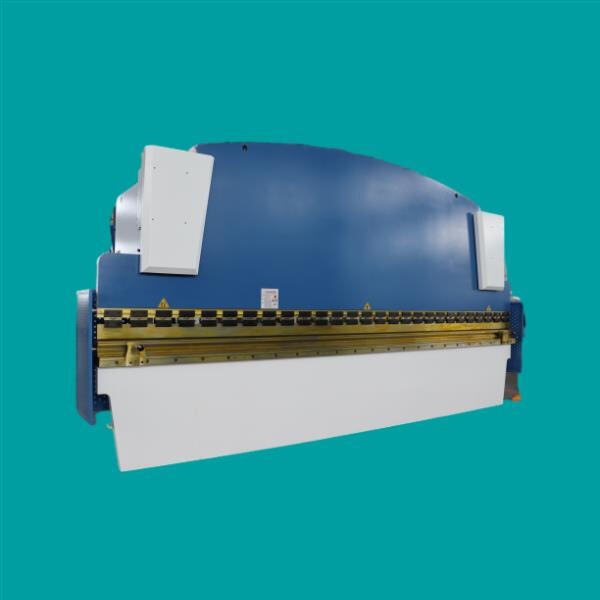

Metal Press Forming There are several methods used in metal press forming. One popular method is stamping, in which a special tool cuts the metal to the appropriate shape. Another technique is referred to as deep drawing, in which metal is stretched into a form. Each method would be used for different products depending on how they need to be shaped.

One of the nice things about metal press forming is that you can get very accurate shapes. That fact also means that products can be built to exact specifications, and they can all fit together seamlessly. It also cuts down on waste, since the metal is used efficiently without extra pieces that must be cut off. This precision, along with the speed, come in handy when you want to get the product in, done, and out quickly.

Metal press forming isn’t just a way to make things quickly; it can also help products look and function better. And makers can use various techniques to produce products that have distinctive shapes and characteristics that are not available with other methods. It results in greater freedom in product design where an object can look good and function well at the same time. Metal press forming is infinite!