Comprehensive Guide to Changing V-Openings on Multi-V Dies

Pre-Change Preparation Checklist

Before beginning the V-opening change process, complete these essentialpreparations:

1. Review Work Order Requirements

Verify material type and thickness

Confirm required bend angles and radii

Identify optimal V-opening size (typically 6-12× material thickness)

2. Gather Necessary Tools

Correct wrench sizes for die clamps

Lifting equipment (for dies over 15kg)

Alignment pins or gauges

Calibration tools

3. Workspace Setup

Clear adequate working space around press brake

Ensure proper lighting

Prepare scrap material for test bends

Detailed Step-by-Step Procedure

1. Machine Safety Lockout

Engage main power disconnect switch

Install physical lockout devices with personal safety locks

Verify zero energy state by attempting to cycle machine

Place "DO NOT OPERATE" tags at all control points

*Safety Note: According to OSHA 1910.147, all servicing and maintenanceactivities require proper lockout/tagout implementation.*

2. Die Clamp Adjustment

Identify clamp type (mechanical, hydraulic, or pneumatic)

For mechanical clamps:

Use calibrated torque wrench for consistent tension

Loosen in star pattern to prevent uneven stress

For hydraulic/pneumatic systems:

Release pressure slowly using bleed valve

Monitor pressure gauges during release

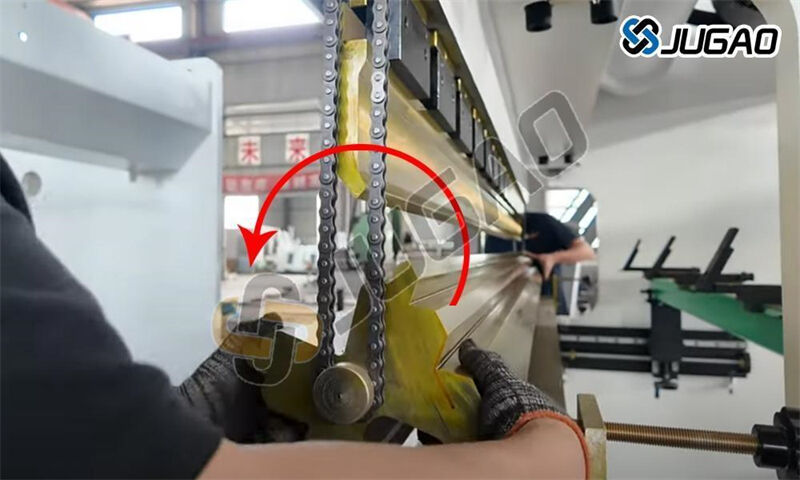

3. Die Rotation Process

1) Lifting Technique

Use balanced lifting points on die

For manual handling:

Maintain straight back posture

Lift with legs, not back

Use team lift for dies over 25kg

2) Rotation Guidance

Clean die grooves before rotation

Align rotation marks with reference indicators

For indexed dies, listen for positive "click" engagement

4. Precision Alignment Verification

Use dial indicators to check:

Vertical alignment (±0.05mm tolerance)

Horizontal parallelism (±0.1mm/m)

Die-to-punch centering

Advanced techniques:

Laser alignment for critical applications

Profile projectors for complex tooling

5. Control System Configuration

1) CNC Parameter Updates

Input exact V-opening dimension

Update material database with:

Elastic modulus

K-factor

Springback coefficients

2) Backgauge Calibration

Perform touch-off procedure

Verify repeatability (±0.02mm)

Compensate for tooling offsets

6. Validation and Testing

Three-Stage Test Protocol:

①Dry run without material

②Test bend on sacrificial material

③Production sample verification

Inspection Criteria:

Bend angle accuracy (±0.5°)

Surface finish quality

Dimensional consistency

Troubleshooting Common Issues

| Symptom | Possible Cause | Corrective Action |

| Uneven bends | Misaligned die | Recheck alignment with precision level |

| Excessive tonnage | Wrong V-opening | Verify material thickness vs. V-width |

| Marked material | Dirty die grooves | Clean and polish contact surfaces |

| Inconsistent angles | Loose clamps | Retorque to manufacturer specs |

Post-Change Maintenance

1. Tooling Care

Apply anti-corrosion coating

Inspect for edge wear

Document usage hours

2. Machine Checks

Verify hydraulic pressure

Test safety interlocks

Clean work area

3. Process Documentation

Record setup parameters

Note any adjustments made

Document test results

Advanced Pro Tips

1. For High-Volume Production:

Implement quick-change die systems

Use RFID-tagged tooling for automatic parameter recall

2. Precision Applications:

Temperature-stabilize tooling

Consider micro-ground dies for critical finishes

3. Safety Enhancement:

Install proximity sensors for die position verification

Implement dual-verification systems for critical setups

This enhanced procedure ensures optimal results while maintaining the highestsafety standards. Always refer to your specific machine's operation manual formanufacturer-recommended practices.