Bilis ng laser welding, lakas ng laser, at kapal ng materyal

Ang ugnayan sa pagitan ng bilis ng laser welding, lakas ng laser, at kapal ng materyal ay mahalaga upang matukoy ang kalidad at kahusayan ng proseso ng pagwawelding. Ang tatlong salik na ito (bilis ng pagwelding, lakas ng laser, at kapal ng materyal) ay magkakaugnay at dapat i-optimize upang makamit ang matibay at walang depekto na mga weld. Mahalaga ang pag-unawa sa kanilang interaksyon para sa mga industriya tulad ng automotive, aerospace, at manufacturing, kung saan napakahalaga ng presisyon at integridad ng materyal.

Pangunahing introduksyon sa makina ng laser welding

Ginagamit ng makina para sa laser welding ang mataas na enerhiyang laser pulse upang mainitan nang lokal ang materyal sa maliit na lugar, at sa pamamagitan ng pagkakalat ng init ay natutunaw ang materyal, upang magawa ang welding. Ang prinsipyo ng paggana nito ay kabilang ang mga sumusunod:

Optikal na pocus: Ginagamit ng makina para sa laser welding ang sinag ng laser na galing sa laser, sa pamamagitan ng mga lens o salamin at iba pang bahagi ng optika, upang ipokus ang enerhiya ng laser sa punto ng pagwewelding.

Pagdaloy ng init: Kapag ang sinag ng laser ay tumama sa ibabaw ng workpiece, ang enerhiya ng laser ay sinisipsip at nagiging enerhiya ng init. Ang enerhiyang ito ay dahan-dahang naililipat kasama ang bahagi ng metal na konduktor ng welding joint sa pamamagitan ng pagkakalat ng init, kaya lumalaki ang temperatura.

Pagkatunaw at paghahalo: Kapag ang ibabaw ng metal ay nailantad sa sapat na mataas na temperatura, nagsisimulang matunaw ang metal at nabubuo ang isang kumukulong pulo. Sa ilalim ng epekto ng sinag ng laser, kumakalat at mabilis na nahahalo ang kumukulong pulo upang magtagpo ang metal na pinag-uugnay.

Paggawa at pagsisid: Matapos itigil ang sinag ng laser, unti-unting lumalamig ang natunaw na pool at nabubuo ang welded joint sa panahon ng proseso ng pagsisid. Sa panahon ng pagsisid, ang mga molekula ng metal ay nagrere-arrange at nagkikristal upang makabuo ng matibay na welded connection.

Mga Kahalagahan ng Laser Welding Machine

Mataas na katiyakan: kayang maabot ang katumpakan sa pagwelding sa antas ng micron, lalo na angkop para sa mga pangangailangan sa pagwelding ng maliit at kumplikadong istruktura.

Mabilis na bilis: Lalo na sa deep melting welding mode, dahil sa pagsusunod-sunod ng laser energy, maliit ngunit malalim ang pool, na nagdudulot ng mabilis na pagwelding at mataas na kahusayan sa produksyon.

Maliit na depekto: Kumpara sa tradisyonal na paraan ng pagwelding, ang laser welding ay may mas mababang init na ipinasok at mas kaunting epekto sa paligid na materyales, na nakakatulong upang bawasan ang pagde-deform pagkatapos mag-weld.

Maliit na thermal affected zone: nakakabawas sa thermal damage sa paligid na materyales at nagpapabuti sa kalidad ng mga welded joint.

Lakas ng laser welding, bilis at kapal ng materyal

1. Laser welding power supply

Ang lakas ng laser ang pangunahing salik na nagtatakda sa lalim ng pagbabad at kabuuang enerhiyang ipinasok habang nagweweld. Ito ang nagtatakda sa init na kailangan upang patunawin ang base na materyales at bumuo ng welding pool. Para sa mas makapal na plato, karaniwang kailangan ang mas mataas na lakas ng laser upang makamit ang sapat na lalim ng pagbabad, samantalang ang manipis na materyales ay mapoprotektahan mula sa labis na pagkatunaw o pagkabutas gamit ang mas mababang lakas.

Mas mataas na lakas: nakakamit ang mas malalim na pagbabad, na angkop para sa pagweweld ng mas makapal na materyales. Gayunpaman, kung sobrang lakas sa manipis na plato, magdudulot ito ng hindi matatag na butas, scattershot (spatter), at kahit mga depekto dahil sa pagkabutas.

Mas mababang pagkonsumo ng kuryente: Higit na angkop para sa manipis na plato, na nagbibigay ng mas mahusay na kontrol at nag-iwas sa labis na pag-init na maaaring magdulot ng pagbaluktot o pagkatunaw ng materyal.

Dapat maingat na piliin ang lakas ng laser batay sa kapal ng materyales upang matiyak ang tamang pagsanib at maiwasan ang mga depekto.

2. Bilis ng paghuhusay

Ang bilis ng pag-weld ay tumutukoy sa bilis na naglalakbay ng laser sa isang welded joint. Ito ay nakakaapekto sa init na input bawat yunit ng haba at isang pangunahing kadahilanan sa pagtukoy sa kalidad ng welding. May direktang kaugnayan sa pagitan ng bilis ng welding at lakas ng laser, dahil ang pagtaas ng isa ay karaniwang nangangailangan ng pag-aayos ng iba upang mapanatili ang ninanais na pagganap ng welding.

Mas mataas na bilis ng welding: Binabawasan ang init na input bawat yunit ng haba ng welding, na kapaki-pakinabang para sa manipis na mga materyales at iniiwasan ang overheating at deformation. Gayunman, kung ang bilis ay masyadong mataas para sa isang naibigay na lakas, ang weld ay maaaring walang pag-agos, na nagreres

Bawasan ang bilis ng welding: Dagdagan ang init na input upang matunaw nang higit at tumawid nang mas malalim sa substrate. Ito ay kapaki-pakinabang para sa mas makapal na mga plato, ngunit maaaring maging sanhi ng sobrang pag-init ng manipis na mga materyales o labis na daloy ng nabubulok na metal.

Ang paggamit ng pinakamahusay na bilis ng welding ay mahalaga upang balansehin ang input ng init at maiwasan ang mga karaniwang depekto sa welding (tulad ng porosity, pag-crack o deformation).

3. Kapaki-pakinabang na mga sangkap

Ang kapal ng mga materyales sa pagwelding ay may mahalagang papel sa pagtukoy ng kinakailangang lakas at pinahihintulutang bilis ng pagwelding. Ang mas makapal na plato ay nangangailangan ng higit na init upang makamit ang buong panlilipad, na nangangahulugan na dapat gumana ang laser sa mas mataas na antas ng kapangyarihan at maaaring kailanganin nitong bawasan ang bilis ng pagwelding upang bigyan ng sapat na oras para sa pagsipsip ng init.

Mas makapal na plato: Kailangan ang higit na enerhiya upang makamit ang buong panlilipad. Dapat magbigay ang laser ng mas mataas na kapangyarihan at dapat mas mabagal ang bilis ng pagwelding upang mailipat ang sapat na enerhiya sa materyal.

Mas manipis na plato: Mas kaunti ang kailangang enerhiya, kaya maaaring bawasan ang kapangyarihan ng laser at palakasin ang bilis ng pagwelding. Ang manipis na materyales ay mas madaling maapektuhan ng pagbaluktot dahil sa init, kaya napakahalaga ng eksaktong kontrol sa mga salik na ito.

Ang interaksyon sa pagitan ng puwersa, bilis at kapal

Ang ugnayan sa pagitan ng bilis ng laser welding, kapangyarihan, at kapal ng sheet ay isang pagbabalanse. Para sa bawat kapal ng materyal, mayroong optimal na kombinasyon ng kapangyarihan ng laser at bilis ng welding upang matiyak ang mataas na kalidad ng welding, tamang lalim ng penetration, at minimum na mga depekto.

Halimbawa, kapag nag-wewelding ng makapal na bakal na plato, ang pagtaas ng kapangyarihan ng laser nang hindi inaayos ang bilis ng welding ay maaaring magdulot ng labis na init, na nagbubunga ng mga depekto tulad ng pagkabaluktot o sobrang lapad ng weld beads. Sa kabilang banda, ang pagbaba ng bilis ng welding nang walang dagdag na kapangyarihan ay maaaring magdulot ng sobrang lalim ng weld, na posibleng magpaso sa materyal. Para sa manipis na materyales, ang sobrang kapangyarihan na pinares sa mabagal na bilis ng welding ay maaaring magdulot ng sobrang pagkatunaw o burn-through ng materyal.

Ugnayan sa pagitan ng bilis ng laser welding at kapal ng plato

Ang makapal na plato ay nangangailangan ng mas mabagal na bilis ng welding

Kapag laser welding ng mas makapal na plato, kailangan ng mas maraming init upang makamit ang buong pagbabad at matiyak ang sapat na lakas ng koneksyon. Kaya naman, mahalaga na bawasan ang bilis ng pagw-welding upang bigyan ng sapat na oras ang sinag ng laser na ilipat ang init sa kabuuang kapal ng materyal. Kung sobrang mabilis ang bilis ng pagw-welding, hindi lubusang mapapasok ng enerhiya ng laser, na maaaring magdulot ng hindi sapat na lalim ng pagsisid, putol-putol na tahi, o hindi sapat na lakas ng joint.

Makapal na plato (>6mm): Dapat mabagal ang bilis ng pagw-welding upang matiyak na ang enerhiya ng laser ay lubusang makakalusot sa kabuuang kapal ng plato upang makabuo ng matatag at mataas na lakas na tahi.

Mas manipis na plato ay maaaring i-weld nang mas mabilis

Kumpara sa makapal na plaka, ang manipis na mga sheet na materyales (mas mababa sa 2mm) ay nangangailangan ng mas kaunting init, na nagbibigay-daan sa mga laser na tumagos nang buong kapal nang mas madali. Nito ay nagpapahintulot sa mas mabilis na bilis ng pagwelding na epektibong pinipigilan ang sobrang pag-init o labis na pagkatunaw, na nag-iwas sa pagbaluktot ng weld o pagkabasag. Bukod dito, ang mas mataas na bilis ng pagwelding ay maaaring makabuluhan sa kabuuang kahusayan.

Manipis na plaka (<2mm): dapat mabilis ang bilis ng pagwelding upang bawasan ang pagbaluktot, pagbasag, at iba pang depekto sa pagwelding na dulot ng sobrang init ng materyal.

Epekto ng lakas ng laser sa bilis ng pagwelding at kapal ng plaka

Ang lakas ng laser ang nagtatakda sa enerhiyang ipinasok habang nagwewelding. Ang mga mataas na lakas na laser ay naglalabas ng mas malakas na init, na siya pong angkop para sa pagwelding ng mas makapal na materyales, samantalang ang mababang lakas na laser ay higit na angkop para sa manipis na mga plaka. Habang pinipili ang bilis ng pagwelding, mahalaga na isabay ang lakas ng laser sa kapal ng plaka upang matiyak ang sapat na pagtagos nang hindi nagdudulot ng sobrang pag-init ng materyal.

Pagwelding ng makapal na plaka gamit ang mataas na lakas na laser

Kapag pinagsasama ang mas makapal na plato, kailangan ng mas mataas na lakas ng laser upang matiyak ang sapat na paglipat ng init sa materyal upang makabuo ng matatag na natunaw na pulo. Kapag pinagsama ito sa mas mabagal na bilis ng pagwawelding, ang enerhiya ng laser ay maaaring mainitan nang pantay ang materyal sa loob ng mas mahabang panahon upang matiyak ang lalim ng pagsusunog.

6kW kapangyarihan ng pagwelding ng makapal na plato (10mm): karaniwang nasa pagitan ang bilis ng pagwelding ng 0.5-1.2m/min.

Pagwawelding ng manipis na plato gamit ang mababang kapangyarihan ng laser

Sa pagwawelding ng manipis na plato, ang mas mababang kapangyarihan at mas mabilis na bilis ay nakakatulong upang maiwasan ang sobrang pag-init at pagbaluktot ng weld. Karaniwan, kapag nasa hanay ng 2-3kW ang kapangyarihan ng laser, ang mga plating may kapal na hindi hihigit sa 2mm ay maaaring maproseso.

2kW kapangyarihan ng pagwelding ng manipis na plato (1mm): karaniwang nasa pagitan ang bilis ng pagwelding ng 5-10m/min.

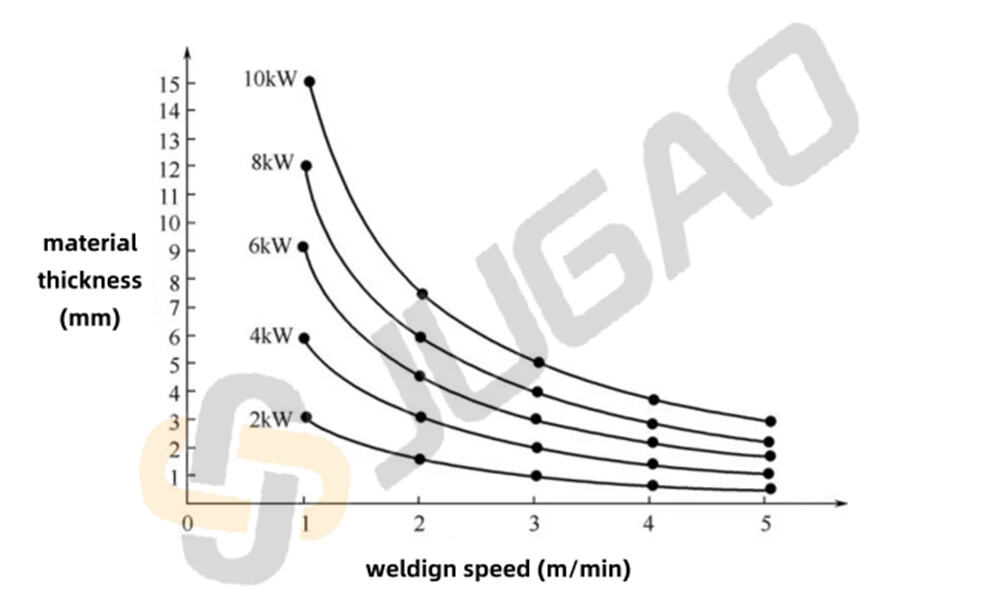

Talahanayan ng paghahambing ng kapangyarihan at bilis ng makina sa pagwawelding gamit ang laser

Narito ang isang paghahambing ng kapangyarihan ng makina sa pagwawelding gamit ang laser at bilis ng pagwelding sa ilalim ng iba't ibang kondisyon ng kapal ng plato:

| Kapal ng materyal (mm) | Laser kapangyarihan (kW) | Bilis ng pagwelding (m/min) |

| 1.0 | 2.0 | 7.0 |

| 2.0 | 3.0 | 4.5 |

| 4.0 | 4.0 | 2.5 |

| 6.0 | 6.0 | 1.2 |

| 8.0 | 8.0 | 0.8 |

| 10.0 | 10.0 | 0.6 |

Manipis na plato (1-2mm): Ang pagsasama ng mababang kapangyarihan (2-3kW) at mataas na bilis ng pagbabakal (5-10 m/min) ay angkop para sa ganitong uri ng pagbubuklod, tinitiyak ang mabilis na operasyon nang hindi nagiging sanhi ng labis na pagkakainit.

Katamtamang kapal at makapal na plato (4-6mm): ang katamtamang kapangyarihan (4-6kW) na pinagsama sa katamtamang bilis ng pagbabakal (1-3 m/min) ay nakatitiyak sa lalim ng pagsusunog at nag-iwas sa labis na lugar na apektado ng init.

Makapal na mga plato (>6mm): Para sa makapal na plato, gumamit ng mataas na kapangyarihan (8-10kW) na pinagsama sa mabagal na pagbabakal (0.5-1 m/min) upang matiyak na sapat ang init na tumatagos sa materyal at nabubuo ang matibay na pagkakakonekta.

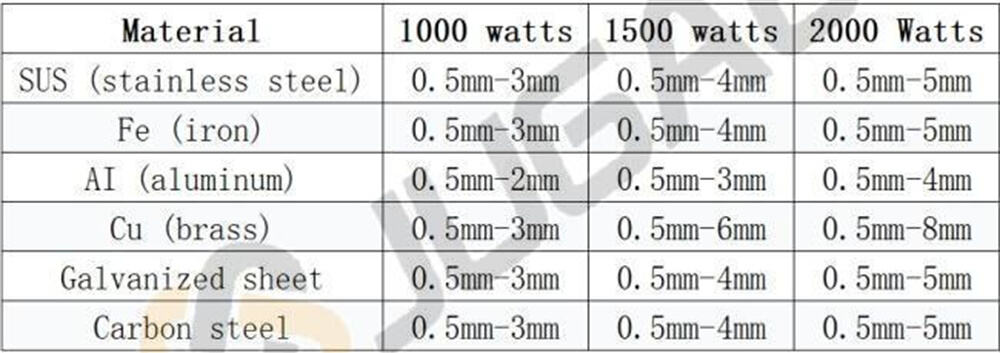

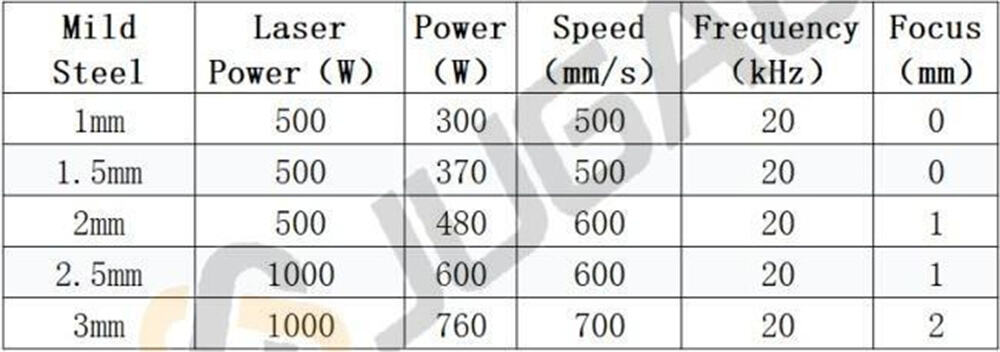

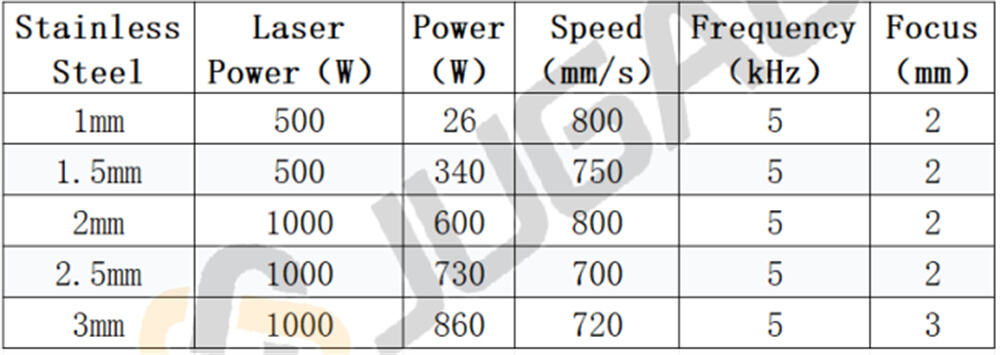

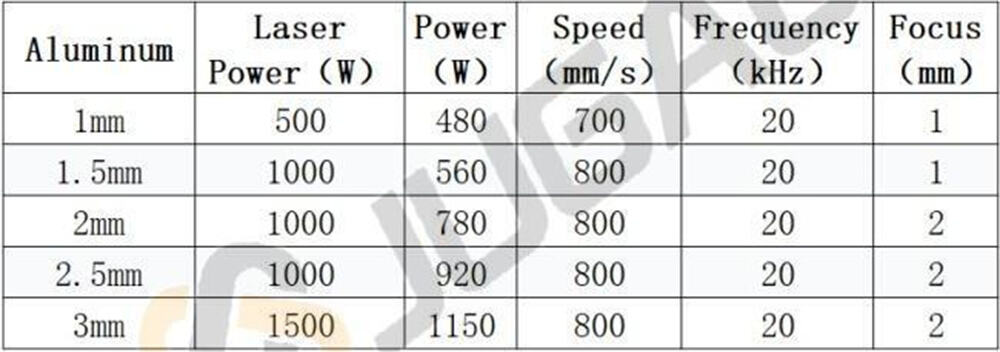

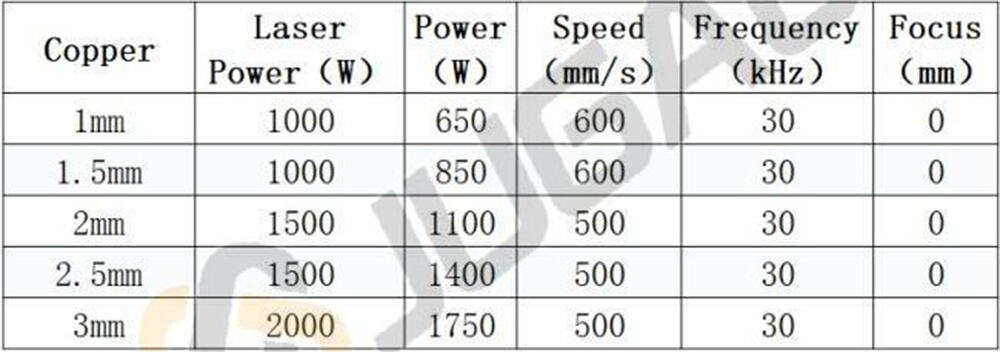

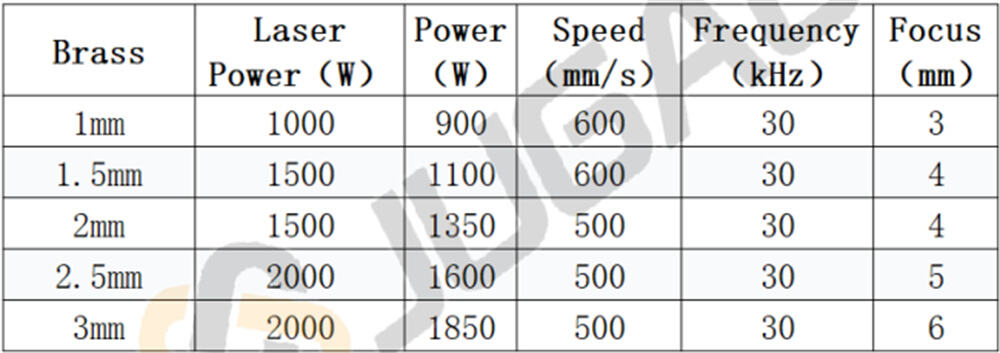

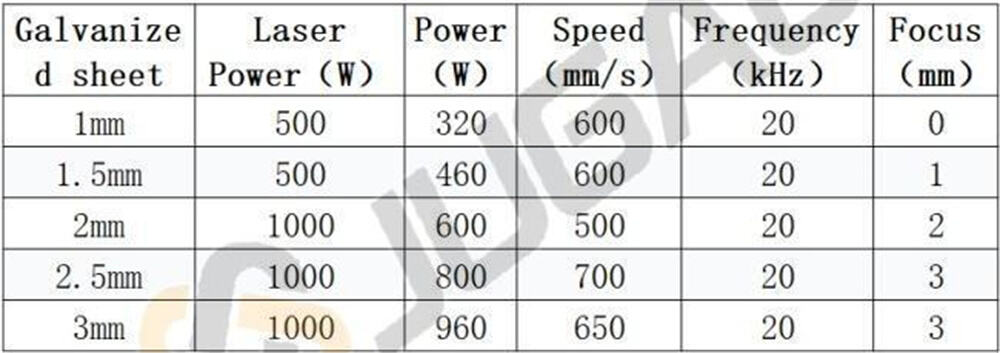

Larawan ng kapangyarihan, kapal, at bilis ng laser welding

Ang laser welding ay isang teknolohiyang pang-precision na nagbibigay ng mabilis at mataas na kalidad na pagbubuklod para sa iba't ibang kapal ng metal. Mahalaga ang ugnayan sa pagitan ng kapangyarihan ng laser, kapal ng materyal, at bilis ng pagbabakal upang makamit ang pinakamahusay na resulta. Ito ay isang komprehensibong tsart na naglalahad ng mga parameter na ito para sa karaniwang mga materyales.

Banayad na Bakal

Stainless steel

Aluminium

Copper

Dilaw na metal

Galvanized Sheet

Kesimpulan

Sa kabuuan, karaniwang nangangailangan ang mas makapal na plato ng mas mataas na kapangyarihan at mas mabagal na bilis ng pagpuputol, habang ang mas manipis na materyales ay nangangailangan ng mas mababang kapangyarihan at mas mabilis na bilis ng pagpuputol. Ang sensitibong balanse na ito ay nagagarantiya ng epektibong paggamit ng enerhiya at mahusay na kalidad ng pagpuputol. Ang pag-unawa sa mga ugnayang ito ay nagbibigay-daan sa mga tagagawa na i-optimize ang kanilang proseso para sa tiyak na aplikasyon, materyales, at kapal, na nagreresulta sa mas matibay at mas maaasahang mga selyo na may mas kaunting depekto.