Øke produksjonseffektivitet med DELEM DA-53T-produktmodus

For bedrifter som ønsker å øke produktiviteten i metallbearbeiding, gir DELEM DA-53T Products Mode en strategisk fordel. Som en kjernefunksjonell komponent integrerer den avanserte teknologiske funksjoner som er utformet for å effektivisere arbeidsflyt, forbedre bøyeav presisjon og redusere driftsforstyrrelser betydelig.

Denne artikkelen undersøker hvordan systematisk bruk av DA-53T Products Mode fører til målbare produktivitetsgevinster – noe som gjør at verksteder kan optimalisere prosesseffektivitet, opprettholde konsekvent produksjonskvalitet og styrke helhetlig produksjonsytelse.

Forståelse av DELEM DA-53T Products Mode

DELEM DA-53T Produkter-modus er en revolusjonerende funksjon som er utviklet for å effektivisere arbeidsflyten i metallbearbeidingsmiljøer. Med avanserte programmeringsfunksjoner lar denne modusen operatører håndtere komplekse bøyesekvenser effektivt med minimal manuell inngripen. Den forenkler bruk av bøyepresser ved å gi intuitive kontrollsystemer, slik at operatører kan konsentrere seg om produktivitet i stedet for prosesskontroll.

I Produktmodus kan eksisterende, tidligere produserte produkter velges for å starte produksjon eller for å bli endret for å lage et lignende produkt. For å lage et nytt program kan Nytt Program brukes fra denne modusen.

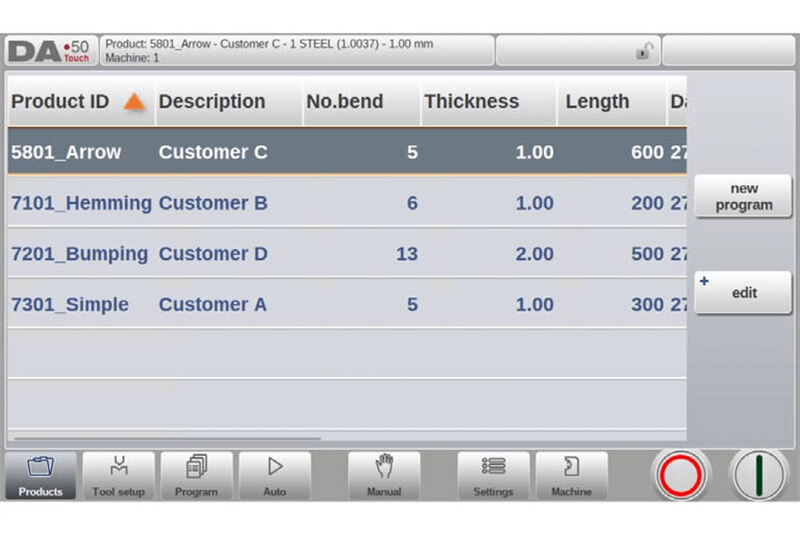

Hovedvisning

DELEM DA-53T-produktmodus gir operatører en klar og oversiktlig visning av programbiblioteket direkte gjennom kontrollgrensesnittet. Denne modusen muliggjør rask valg og lasting av produktprogrammer, og viser viktige detaljer – inkludert produkt-ID, beskrivelse, antall bøyninger og dato for siste endring eller bruk – for å støtte effektiv programhåndtering og informerte beslutninger.

Når et produktprogram er aktivt, vises ID-en tydelig øverst på skjermen for enkel referanse. Å laste et program er intuitivt: trykk bare på produkt-ID-en eller en hvilken som helst oppføring i raden. Hvis biblioteket inneholder flere produkter enn det som kan vises om gangen, kan listen rulles glatt for å finne ønsket element. Et enkelt trykk velger produktet og aktiverer det i kontrollsystemet.

Ved å lette rask navigering og valg innen biblioteket for programmer, forbedrer DELEM DA-53T Products-modus betydelig arbeidsflyt effektivitet og reduserer ikke-produktiv tid – en avgjørende fordel i miljøer med presisjonsdreven produksjon.

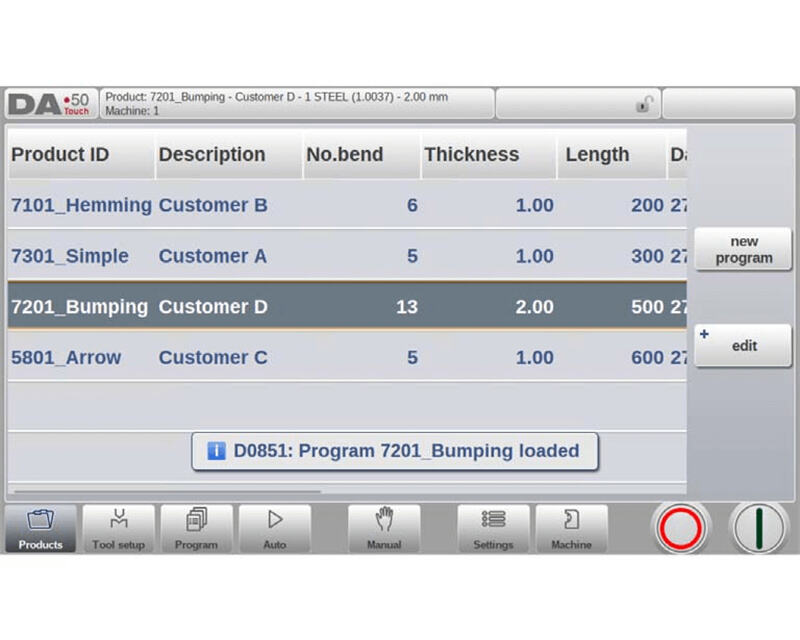

Produktutvalg

DELEM DA-53T Products-modus øker produktivitet ved å forenkle produktvalg. Med ett enkelt trykk lastes produktene inn i minnet, noe som tillater umiddelbar produksjonsstart ved å velge «Auto». Denne strømlinet tilnærming, kombinert med enkel navigering gjennom verktøyoppsett og numerisk program, øker driftseffektiviteten i metallbearbeidelse.

Nøkkelfunksjoner i DELEM DA-53T Products-modus

Effektiv programmeringsfunksjonalitet

DELEM DA-53T Produkter-modus er utstyrt med forbedrede programmeringsfunksjoner som gir nøyaktig kontroll over produksjonsprosesser. Operatører kan enkelt legge inn ulike bøyingparametere og sette dem til gjentakelse, noe som sikrer konsistens mellom serier. Denne funksjonen bidrar ikke bare til å redusere oppstartstider, men også til å minimere feil, noe som direkte øker produktiviteten.

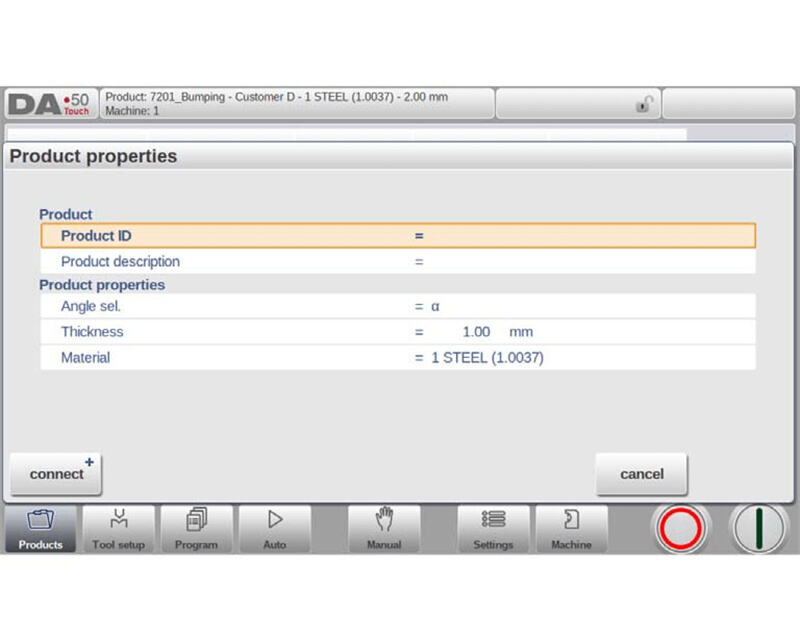

For å starte et nytt numerisk program, trykk på Nytt program. Når Nytt program er valgt, starter programmeringen med generelle detaljer som f.eks. produkt-ID, tykkelse og materiale.

Redigere, kopiere og slette et produkt eller program

I DELEM DA-53T Produkter-modus er effektiv håndtering av produkter avgjørende for å øke produktiviteten.

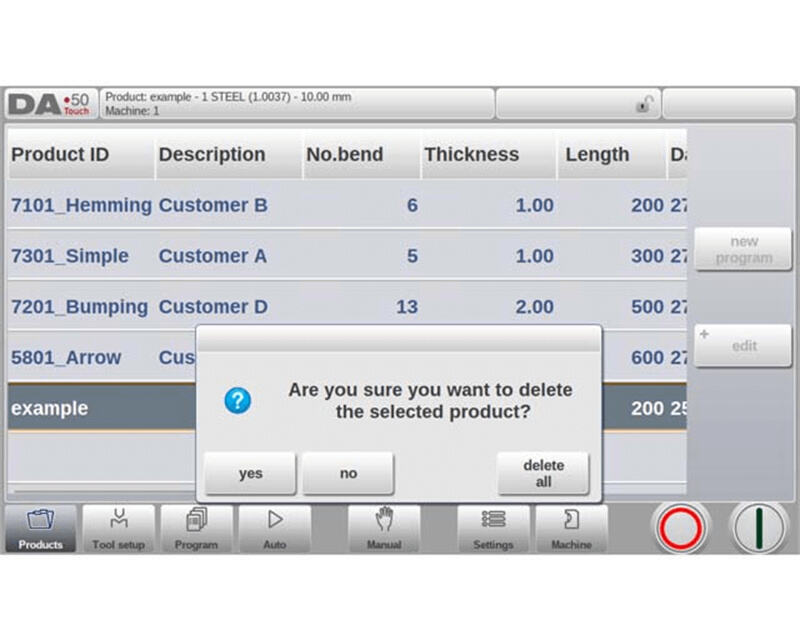

For å slette et produkt, velg det ved å trykke på det, og bruk deretter Rediger-menyen for å initiere og bekrefte sletting. For massesisering er alternativet Slett alle tilgjengelig.

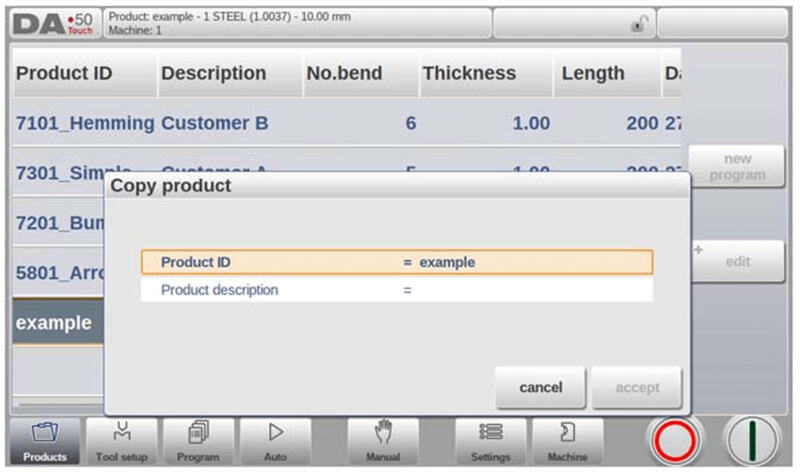

Å kopiere et produkt er like enkelt – velg programmet, trykk på Rediger og velg Kopier. Denne handlingen oppretter en nøyaktig kopi, inkludert alle verktøysoppsett, noe som muliggjør rask duplikering uten manuell omprogrammering.

Ved å forenkle disse prosessene, effektiviserer DELEM DA-53T Produkter-modus driftsprosesser og blir dermed et uvurderlig verktøy for å øke produktiviteten i enhver metallbearbeidingsomgivelse.

Endre produktnavn

DELEM DA-53T Produkter-modus inkluderer en intuitiv funksjon for å endre produktnavn som bidrar til strømlinjeformet verkstedhåndtering. For å endre navn på et produkt, velg ønsket program, aktiver funksjonen 'Rediger' og velg 'Endre navn' fra menyen. Det nye navnet kan deretter tilordnes i én enkel operasjon.

Denne bevisst enkle men kraftige funksjonen minimerer driftskompleksitet, hjelper til med å forhindre identifikasjonsfeil og støtter helhetlig prosesseffektivitet – noe som muliggjør jevnere integrering av arbeidsflyt og mer organiserte metallbearbeidingsoperasjoner.

Fordeler med DELEM DA-53T-produktmodus i daglig drift

Redusert oppsettid

Ved å bruke DELEM DA-53T-produktmodus kan operatører raskt lagre og laste inn etablerte programmer, noe som betydelig reduserer innstillingstid for gjentatte oppgaver. Denne funksjonen er spesielt nyttig i masseproduksjon der hvert sekund teller, og maksimerer maskinens oppetid og produksjonskapasitet.

Økt produksjonsnøyaktighet

DELEM DA-53T-produktmodus er utviklet for å øke presisjonen i bøyeoperasjoner. Ved å automatisere mange parametere og gi operatører avanserte overvåkingsverktøy, sikrer denne modus høyere nøyaktighet og reduserer avfall, noe som fører til kostnadsbesparelser og bedre resultat.

Forbedret brukervennlighet og opplæring

Denne modusen er ikke bare kraftfull, men også intuitivt designet, noe som reduserer læringskurven for nye operatører. Det brukervennlige grensesnittet akselererer opplæringsprosessen, slik at teamene raskt kommer i gang og kan fokusere på å forbedre produktiviteten uten omfattende nedetid.

Konklusjon

Kort fortalt gir DELEM DA-53T Products-modus betydelige produktivitetsgevinster i metallbearbeidelse gjennom sin effektive programmeringsmiljø og intuitive produktadministrasjonsverktøy – inkludert redigering, kopiering, sletting og omdøpingsfunksjoner. Disse integrerte funksjoner forkorter oppsettssykluser, forbedrer produksjonsnøyaktighet og øker operativ tilgjengelighet, noe som muliggjør rask opptak av nye operatører. Ved å implementere disse funksjonene systematisk kan verksteder oppnå en mer strømt foretatt arbeidsflyt og optimalisert ytelse på bøyepresser.

For å fullt ut utnytte fordelene med DELEM DA-53T Products-modus, anbefaler vi grundig kjennskap med dets funksjonssett og konsekvent bruk i daglige operasjoner. For ytterligere tekniske detaljer eller spesialisert veiledning, står vårt supportteam JUGAO CNC MACHINE til rådighet. Vi oppfordrer også til å utforske vår utvidede samling av driftsressurser for å ytterligere utvikle din ferdighet innen bøyepresssystemer og produksjonsoptimalisering.